10 月 . 30, 2024 19:07 Back to list

differential pressure gauge with needle for water filter quotes

Understanding Differential Pressure Gauges with Needle Valves for Water Filters

In the world of water filtration systems, precise measurements and control are critical to ensuring optimal performance and efficiency. One essential tool for monitoring pressure differences within filtration systems is the differential pressure gauge, often equipped with a needle valve. This article delves into the importance of these gauges and their components, highlighting their role in maintaining effective water filtration.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument designed to measure the pressure difference between two points in a fluid system. In the context of water filters, this instrument enables operators to monitor the pressure drop across the filter media. A notable feature of these gauges is their ability to provide insights into the condition of the filter as a filter becomes clogged with particulates, the pressure differential increases. Thus, by observing the gauge, operators can determine when maintenance or replacement is necessary, preventing reduced flow rates and ensuring water quality.

The Role of the Needle Valve

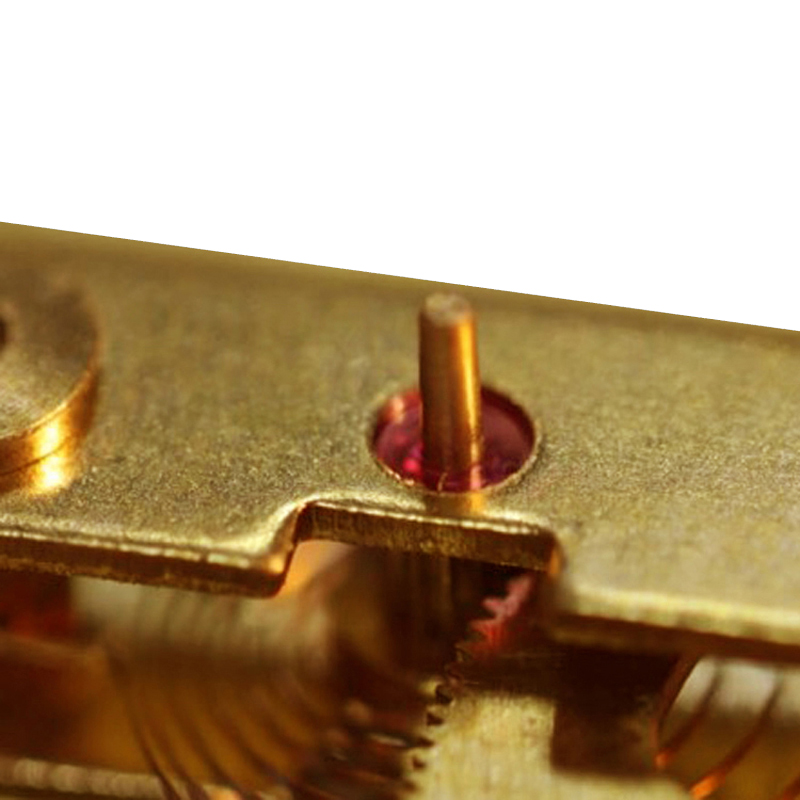

When paired with a needle valve, the functionality of a differential pressure gauge is further enhanced. A needle valve allows for fine control of fluid flow, enabling precise adjustments to the system's pressure. This is particularly beneficial in applications where accurate pressure settings are critical, as it allows operators to calibrate the pressure differential to ensure optimal flow characteristics through the filter.

Moreover, the needle valve can assist in isolating the pressure gauge from the system during maintenance or calibration. By shutting off the flow, technicians can safely and easily remove the gauge for cleaning or replacement without disrupting the entire system. This minimizes downtime and maintains system efficiency.

differential pressure gauge with needle for water filter quotes

Benefits of Using Differential Pressure Gauges in Water Filtration

1. Performance Monitoring By providing real-time data on filter performance, differential pressure gauges help operators identify issues before they lead to failures or inefficiencies.

2. Cost Efficiency Regular monitoring can extend the life of filters by ensuring they are not operated beyond their optimal capacity, thus reducing replacement costs.

3. Enhanced Water Quality Maintaining appropriate filtration conditions directly contributes to the quality of the water output, ensuring compliance with health and safety standards.

4. Preventative Maintenance By establishing routine checks based on pressure readings, operators can implement preventative strategies, reducing emergency repairs and improving overall system reliability.

Conclusion

In summary, differential pressure gauges equipped with needle valves are invaluable components in water filtration systems. They provide critical data that informs operational decisions, improves maintenance strategies, and ensures water quality. As the demand for efficient water purification increases, leveraging such technology will be essential for both residential and industrial applications. Investing in high-quality differential pressure gauges and understanding their operational significance will ultimately lead to better filtration outcomes and enhanced water safety.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025