9 月 . 14, 2024 12:03 Back to list

dual diaphragm differential pressure gauges factory

Understanding Dual Diaphragm Differential Pressure Gauges

Dual diaphragm differential pressure gauges play a crucial role in various industrial applications by precisely measuring pressure differences between two points. These devices are essential in maintaining the efficiency and safety of processes in fields such as oil and gas, pharmaceuticals, and waste management.

The core mechanism of a dual diaphragm differential pressure gauge involves two flexible diaphragms that separate the high and low-pressure chambers. When there is a pressure difference, the diaphragms deform accordingly, causing a mechanical movement that is then translated into a readable measurement on the gauge dial. This design enhances accuracy and reliability, as each diaphragm is crafted to minimize the effects of temperature fluctuations and other environmental factors.

One of the key advantages of dual diaphragm gauges is their ability to handle corrosive and extreme conditions. Many models are constructed from robust materials such as stainless steel or specialized alloys, making them suitable for challenging environments. This robustness extends the lifespan of the gauge and decreases the need for frequent recalibrations or replacements, making them a cost-effective solution for industries requiring consistent performance.

dual diaphragm differential pressure gauges factory

These gauges come with a variety of features to cater to specific application needs. For instance, some models are equipped with built-in temperature compensation to enhance measurement accuracy further. Others may offer digital interfaces, allowing for easy integration with modern control systems and providing real-time monitoring and data logging capabilities. These advancements make dual diaphragm differential pressure gauges not only reliable but also adaptable to the increasing demands of modern industrial processes.

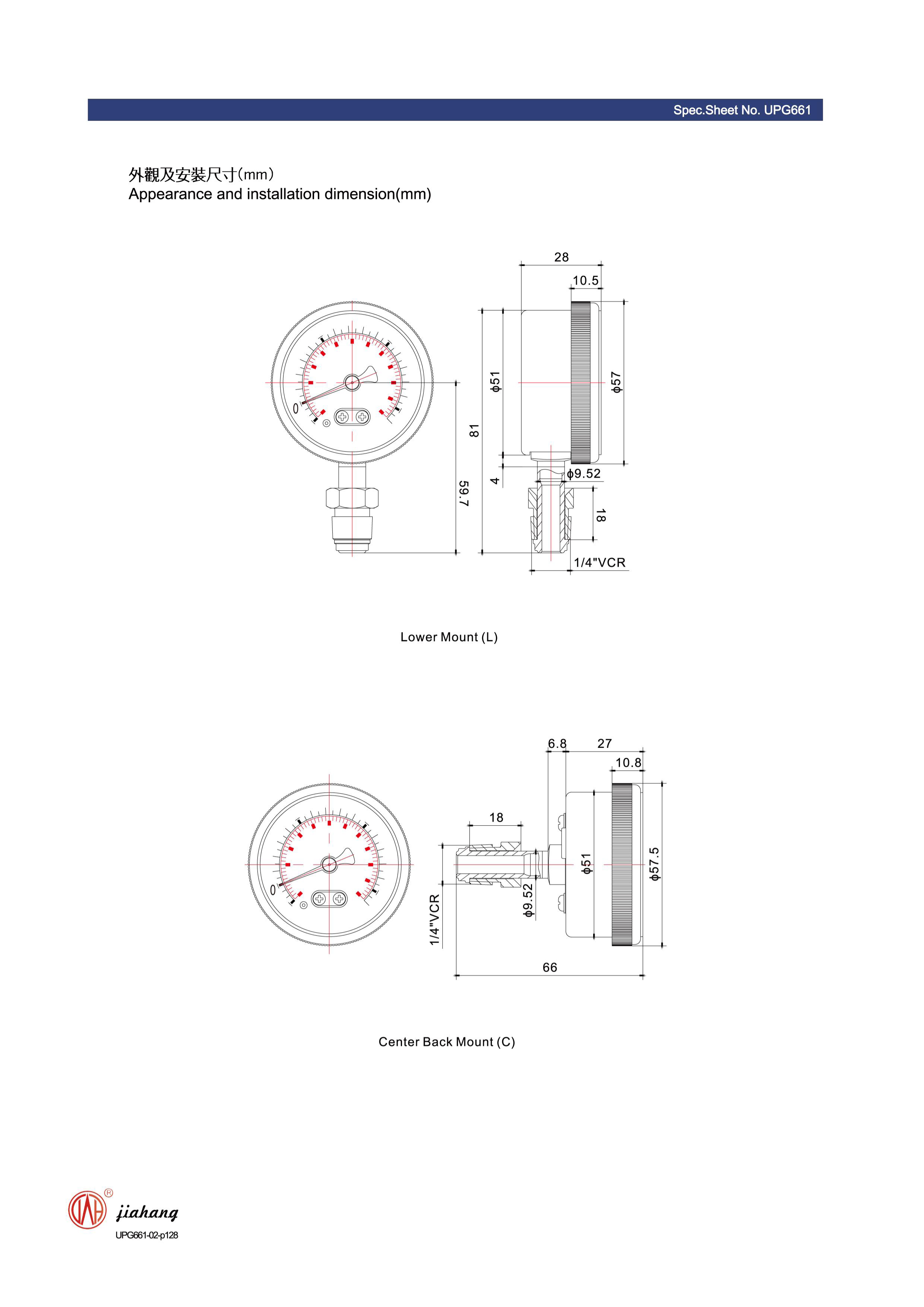

Installation of these gauges is straightforward, thanks to their standard connections and mounting options. However, proper calibration and regular maintenance are vital for ensuring optimal performance. Industries typically conduct routine checks to verify the accuracy of the readings, especially in critical applications where even minor pressure deviations can result in significant operational issues.

In summary, dual diaphragm differential pressure gauges represent a fundamental component in the monitoring and control of pressure in various industrial environments. Their design promotes durability and precision, making them suitable for a wide range of applications. As technology continues to advance, these gauges will likely evolve further, incorporating digital features that enhance their functionality and user-friendliness. For industries looking to improve efficiency and ensure safety, investing in high-quality dual diaphragm differential pressure gauges is an essential step towards achieving operational excellence.

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025