11 月 . 24, 2024 11:02 Back to list

Differential Pressure Gauges for Various Applications from General Instruments

Understanding Differential Pressure Gauges A Focus on General Instruments Products

Differential pressure gauges are crucial instruments in various industries, where they provide vital information about the pressure difference between two points in a system. These gauges are essential in applications ranging from HVAC systems to industrial processes, where monitoring the pressure drop across filters, pumps, and other components is critical for optimal performance and safety.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points. This capability is significant as it helps operators understand fluid flow, detect blockages, and monitor equipment performance. The fundamental operation of these gauges relies on the physical principle of pressure differentials, where two separate pressure measurements are compared. The resulting measurement can indicate whether a system is functioning correctly or if maintenance is required.

The Importance of Differential Pressure in Industrial Applications

In industrial settings, differential pressure measurement is vital for several reasons. Monitoring differential pressure can help predict system failures, optimize energy efficiency, and maintain the desired process conditions. For instance, in HVAC systems, maintaining specific pressure differentials across filters is crucial to ensuring clean air delivery and efficient operation. In hydraulic systems, differential pressure readings can indicate whether a pump is operating within its optimal range or if there are blockages requiring attention.

Features of General Instruments Differential Pressure Gauges

General Instruments offers a range of differential pressure gauge products designed for accuracy, reliability, and ease of use. Below are some notable features that set these gauges apart

1. High Accuracy General Instruments’ differential pressure gauges are known for their precision, enabling users to obtain accurate measurements essential for monitoring and control processes.

2. Durability Constructed with robust materials, these gauges are designed to withstand harsh industrial environments. This durability ensures a longer lifespan and reduces the need for frequent replacements.

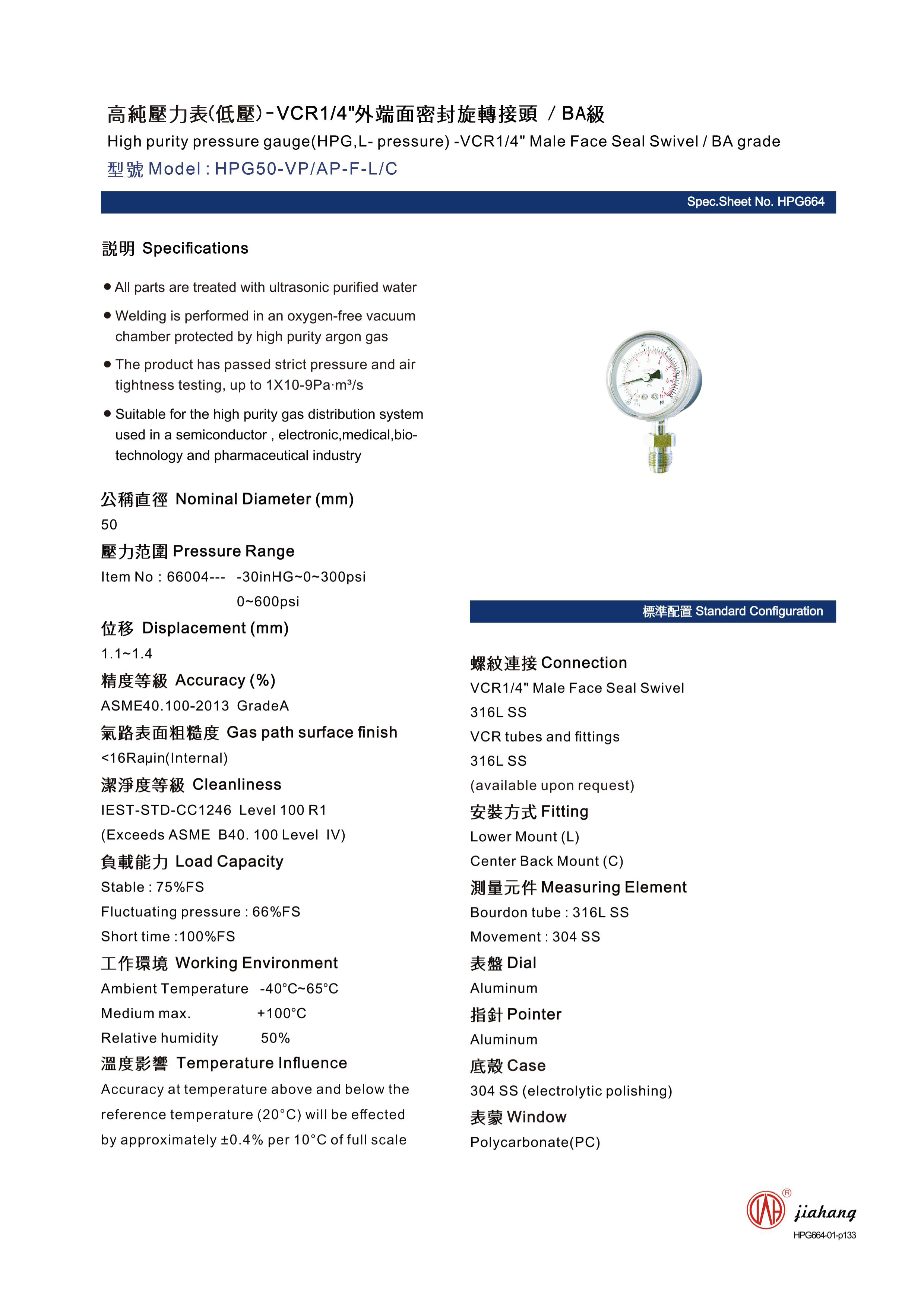

general instruments differential pressure gauge products

3. Variety of Models General Instruments provides various models suited for different applications, including analog and digital gauges. This variety allows users to select the most appropriate instrument based on their specific requirements.

4. User-Friendly Design Many of the gauges feature easy-to-read displays and intuitive controls, making them accessible to operators and reducing the likelihood of errors during operation.

5. Versatility The differential pressure gauges can accommodate various fluids and gases, which makes them suitable for multiple industries, including manufacturing, water treatment, and energy production.

6. Customization Options For specialized applications, General Instruments offers customization options, allowing users to configure gauges tailored to their specific operational needs, including pressure range, scale type, and connection standards.

Applications of Differential Pressure Gauges

The applications for differential pressure gauges are extensive. In the pharmaceutical industry, they ensure cleanroom environments are maintained, helping to meet stringent regulations. In the food and beverage industry, they monitor filtration processes critical for maintaining product quality. In oil and gas, they are used to monitor pipeline conditions, and in water treatment facilities, they help ensure the efficient operation of pumps and filters.

Conclusion

Overall, General Instruments’ differential pressure gauges offer critical support for industries relying on accurate pressure measurement to maintain operations, safety, and efficiency. The combination of high accuracy, durability, and versatility makes these instruments invaluable in various applications. When selecting a differential pressure gauge, considerations should include the specific demands of the application, including the medium being measured and the environmental conditions. With the right gauge, industries can enhance their operational efficiency, predict maintenance needs, and ensure compliance with safety standards.

As technology continues to evolve, instruments like those offered by General Instruments will play a pivotal role in the innovation and efficiency of industrial processes, paving the way for safer and more effective operations across the board.

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025