9 月 . 08, 2024 02:48 Back to list

high quality omega differential pressure gauge

High-Quality Omega Differential Pressure Gauge A Critical Tool for Precision Measurement

In various industrial applications, differential pressure gauges are essential for monitoring and controlling processes. Among the numerous options available on the market, the high-quality Omega differential pressure gauge stands out for its precision, durability, and versatility. This article delves into the significance of differential pressure measurement and the compelling advantages offered by Omega gauges.

Differential pressure gauges measure the difference in pressure between two points in a system. This measurement is crucial for numerous applications, including monitoring filtration systems, HVAC operations, and fluid dynamics. By providing real-time data on pressure differences, these gauges help maintain optimal operational conditions, prevent equipment failures, and ensure safety in processes that involve gaseous or liquid fluids.

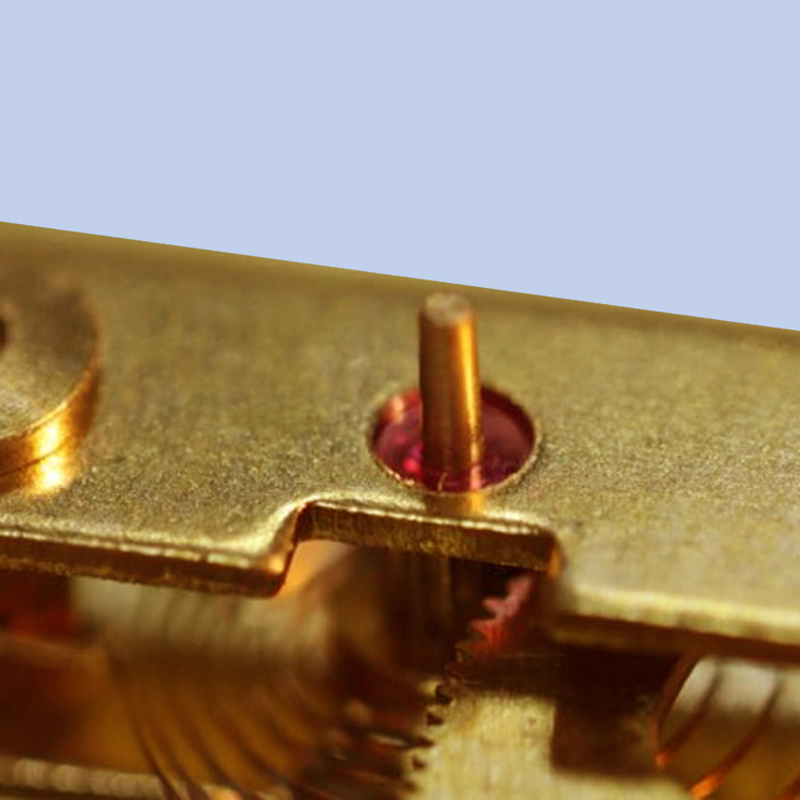

Omega Engineering, a reputable manufacturer known for its high-quality measurement and control solutions, produces differential pressure gauges that cater to a wide range of industries—from pharmaceuticals to petrochemicals. One of the key features of Omega differentials is their accuracy. With precision readings often exceeding ±0.25% of full scale, these gauges enable operators to make informed decisions based on reliable data. This level of accuracy is crucial in applications where even slight deviations in pressure can lead to significant consequences, such as equipment damage or safety hazards.

high quality omega differential pressure gauge

Another remarkable aspect of Omega differential pressure gauges is their robust design. Constructed from high-grade materials, these gauges are built to withstand harsh environmental conditions, including extreme temperatures and corrosive substances. This durability ensures that they deliver consistent performance across various settings, extending the product's lifespan and reducing maintenance costs.

In addition to traditional analog models, Omega offers digital differential pressure gauges that incorporate advanced technology for enhanced functionality. Digital gauges display measurements with greater clarity and often come equipped with features such as data logging capabilities, alarms for exceeding set pressure thresholds, and remote monitoring options. These modern advancements facilitate better process control and enable operators to respond quickly to any fluctuations in pressure.

Ease of installation and calibration further sets Omega differential pressure gauges apart. Many models feature user-friendly interfaces and straightforward installation procedures, allowing for quick integration into existing systems. Additionally, their calibration is generally uncomplicated, ensuring operators can maintain accuracy without extensive downtime.

In conclusion, the high-quality Omega differential pressure gauge is an invaluable tool for industries that rely on precise pressure measurements. Its accuracy, durability, versatility, and modern features make it an ideal choice for ensuring optimal operational performance. Whether in a manufacturing facility or a laboratory, investing in an Omega differential pressure gauge translates to enhanced safety, efficiency, and reliability in critical processes. As industries continue to evolve, these gauges will undoubtedly play a central role in meeting the growing demands for precision and quality.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025