8 月 . 21, 2024 21:11 Back to list

Innovative Diaphragm Seal Pressure Gauge Solutions by Wika for Reliable Measurements

The Importance of Diaphragm Seal Pressure Gauges A Look at Wika Instruments

In various industrial applications, accurate pressure measurement is critical for ensuring optimal performance, safety, and reliability. One of the most effective tools for achieving this is the diaphragm seal pressure gauge. Notably, Wika Instruments has become a recognized leader in this field, providing innovative solutions that cater to the diverse needs of industries around the globe.

Understanding Diaphragm Seal Pressure Gauges

A diaphragm seal pressure gauge is a device designed to measure the pressure of fluids or gases while protecting the internals from harsh conditions. This type of gauge employs a flexible diaphragm that separates the measuring element from the process medium. As the process pressure changes, the diaphragm flexes, translating this movement into a pressure reading. The diaphragm seal acts as a barrier, preventing contact between the measured medium and the internal components of the gauge, thereby prolonging its lifespan and ensuring accurate readings.

The Wika Advantage

Wika Instruments, a globally renowned manufacturer of pressure measuring devices and sensors, is celebrated for its diaphragm seal pressure gauges

. They offer a diverse range of products specifically designed to meet the rigorous demands of various industries, including chemical processing, food and beverage, pharmaceuticals, and oil and gas.One significant advantage of Wika's diaphragm seal gauges is their ability to handle extreme conditions. These gauges can be constructed using a variety of materials that provide excellent corrosion resistance, such as stainless steel, enabling them to withstand aggressive environments where conventional gauges would fail. Additionally, Wika offers gauges that can function in high-temperature and high-pressure applications, ensuring reliability even under challenging circumstances.

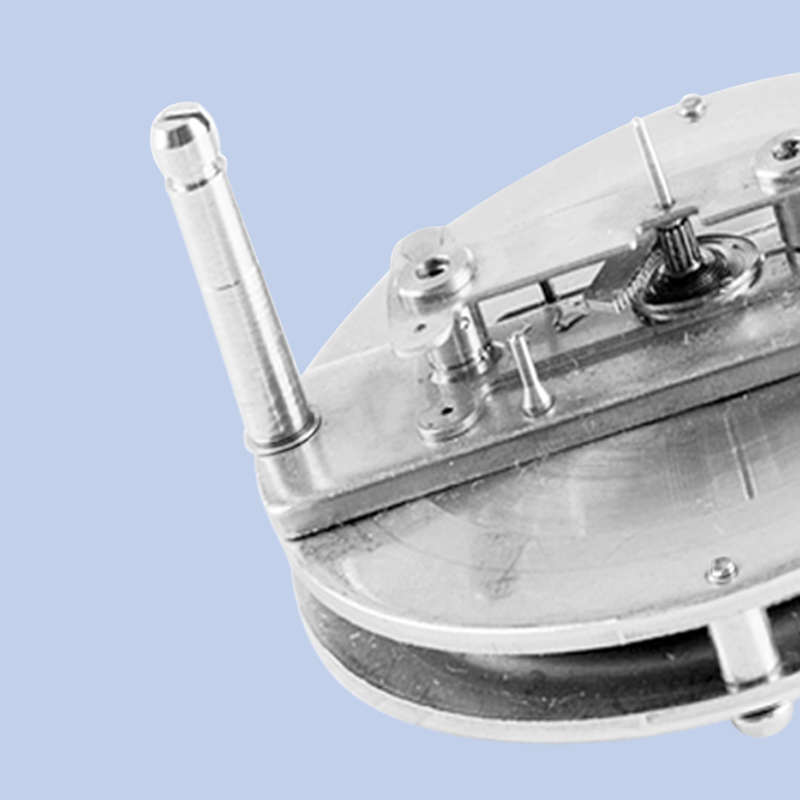

famous diaphragm seal pressure gauge wika

Applications in Industry

Diaphragm seal pressure gauges are invaluable in numerous applications. In the chemical industry, for instance, they are used to monitor the pressure of corrosive fluids, ensuring that processes remain within safe limits. In the food and beverage industry, where hygiene standards are paramount, Wika’s diaphragm seal gauges are designed to meet stringent regulations, offering sanitary solutions that prevent contamination.

Furthermore, in the pharmaceutical sector, accurate pressure measurement is essential for maintaining the integrity of products. Wika's solutions ensure that the pressure remains consistent during production processes, which is vital for quality assurance and compliance with health regulations.

Customization and Innovation

Wika understands that each industry presents unique challenges, which is why they offer customizable diaphragm seal pressure gauges. Clients can choose from various configurations, materials, and sizes, ensuring that the gauge perfectly fits their specific application requirements. Moreover, Wika continuously invests in research and development, leading to innovative features such as smart sensors that integrate with digital devices for real-time monitoring and data analysis.

Conclusion

In conclusion, diaphragm seal pressure gauges, particularly those manufactured by Wika Instruments, play a vital role in various industrial applications. Their ability to provide accurate, reliable pressure measurements in harsh and demanding environments makes them indispensable for maintaining operational efficiency and safety. With a commitment to innovation, customization, and quality, Wika continues to lead the way in pressure measurement technology, helping industries to overcome their challenges and thrive in a competitive landscape. Whether in chemical processing, food and beverage production, or pharmaceutical manufacturing, Wika's diaphragm seal pressure gauges offer the solutions that modern industries need.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025