9 月 . 25, 2024 20:44 Back to list

oem pressure diaphragm

Understanding OEM Pressure Diaphragms Essential Components in Modern Applications

In the realm of industrial and technical applications, the demand for precision and reliability is paramount. One of the critical components that facilitate these attributes is the OEM (Original Equipment Manufacturer) pressure diaphragm. This article delves into the significance of OEM pressure diaphragms, their design, functionality, and applications across different industries.

What is a Pressure Diaphragm?

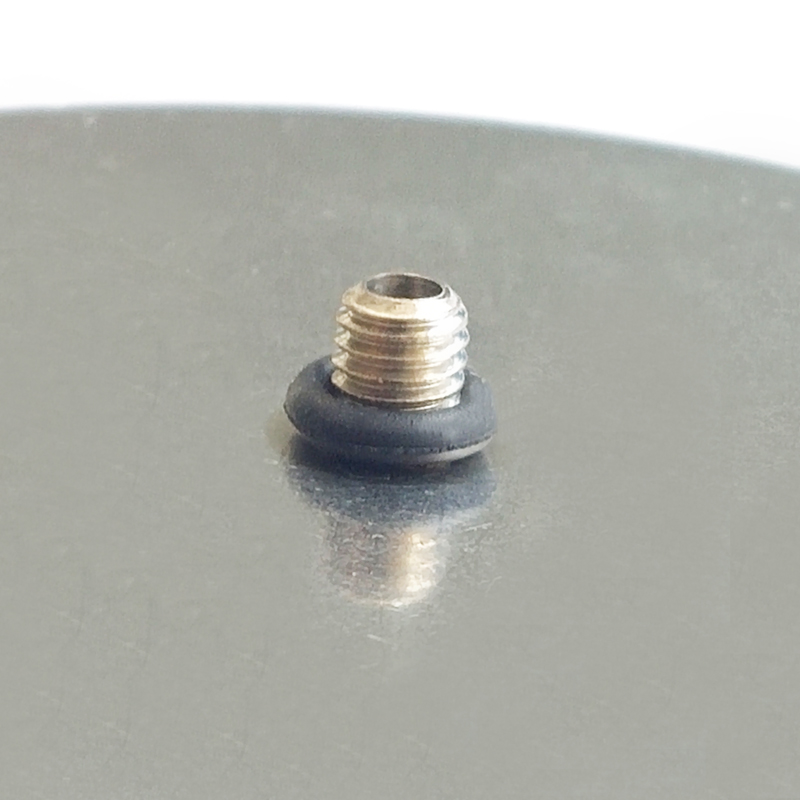

A pressure diaphragm is a thin, flexible membrane that separates two chambers and is vital in measuring and controlling pressure. Typically made from materials such as elastomers or metal, diaphragms are designed to deform under pressure changes. In essence, they act as a barrier allowing for pressure transmission without direct contact with the fluid or gas inside. This is crucial for both safety and accuracy in numerous applications.

The Role of OEM in Pressure Diaphragms

OEM pressure diaphragms are specifically manufactured by companies that produce components to be integrated into products sold by other brands. The term “OEM” signifies that these diaphragms are tailored to meet the precise specifications and requirements of the end user’s equipment. Manufacturers can design these diaphragms for various pressure ranges, chemical resistances, and even temperature tolerances, ensuring they perform optimally in their intended environment.

Design Considerations

The design of an OEM pressure diaphragm involves a number of critical factors

1. Material Selection The choice of material is often dictated by the application requirements. Common materials include rubber, silicone, and metals like stainless steel, which provide durability and resistance to corrosion.

2. Thickness and Geometry The diaphragm’s thickness can influence its response time and pressure sensitivity. Engineers must consider the geometry that allows for the required flex while maintaining structural integrity.

oem pressure diaphragm

3. Sealing Mechanisms Effective sealing is crucial to prevent leaks, especially in high-pressure systems. OEM pressure diaphragms must be designed to handle the specific sealing requirements of each application.

4. Compatibility The diaphragm must be compatible with the other components it interfaces with, including valves, sensors, and any fluids or gases contained within the system.

Applications Across Industries

OEM pressure diaphragms are employed in a range of applications, reflecting their versatility and critical role. Some prominent fields where they are used include

- Automotive In vehicles, pressure diaphragms are used in fuel systems, brakes, and HVAC systems to ensure optimal performance and safety. They help manage hydrodynamics and maintain necessary pressure levels.

- Aerospace In the aerospace industry, these diaphragms are essential for various instruments that measure atmospheric pressure or the performance of engines, where accuracy is vital.

- Medical Devices OEM pressure diaphragms are integral in devices such as respiratory equipment, infusion pumps, and blood pressure monitors. They enable precise measurements and control necessary for patient safety.

- Industrial Automation Diaphragms are crucial in pressure sensors, switches, and regulators used in manufacturing processes, ensuring accurate monitoring and regulation of system pressures.

Conclusion

OEM pressure diaphragms are a testament to engineering innovation, providing essential functions in various applications. Their ability to facilitate precise measurements while ensuring safety makes them indispensable in numerous industries. As technology continues to advance, the design and manufacturing of these diaphragms will evolve, paving the way for enhanced reliability and performance in modern applications. From automotive to aerospace, these components will continue to play a pivotal role in transforming how industries operate, ensuring that pressure control remains both efficient and effective. Understanding the nuances of OEM pressure diaphragms is vital for anyone involved in design, manufacturing, or application across diverse fields.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025