9 月 . 23, 2024 00:49 Back to list

pressure gauge with diaphragm factories

Understanding Diaphragm Pressure Gauges A Key to Precision Measurement

Pressure gauges are vital instruments widely used across various industries to monitor and measure the pressure of gases and liquids. Among the many types available, diaphragm pressure gauges stand out for their accuracy, durability, and versatility. These gauges utilize a flexible diaphragm to sense pressure changes, making them ideal for diverse applications, from oil and gas to pharmaceuticals.

What is a Diaphragm Pressure Gauge?

A diaphragm pressure gauge consists of a sealed chamber with a flexible diaphragm that deforms under pressure. As the pressure increases or decreases, the diaphragm moves, and this movement is translated into a dial reading or electronic signal that indicates the pressure level. The design is particularly effective for measuring low to medium pressures and can be utilized in harsh environments.

Applications and Industries

Diaphragm pressure gauges are commonly found in industries such as chemical processing, food and beverage, and HVAC systems. Their ability to handle viscous or corrosive fluids, paired with a protective casing, makes them suitable for challenging conditions. For example, in the chemical manufacturing sector, these gauges ensure that processes remain within safe pressure levels, preventing accidents and enhancing operational efficiency.

Benefits of Diaphragm Pressure Gauges

pressure gauge with diaphragm factories

1. Accuracy Diaphragm gauges offer high accuracy and minimal hysteresis, ensuring that readings are reliable. 2. Durability Constructed from robust materials, they can withstand extreme temperatures and corrosive environments, ultimately leading to a longer lifespan. 3. Low Maintenance The simple mechanical design requires less maintenance compared to electronic gauges, which may involve more components that could fail. 4. Versatility They can measure a wide range of pressures and are suitable for various fluids, including gases, oils, and chemicals.

Selecting the Right Diaphragm Pressure Gauge

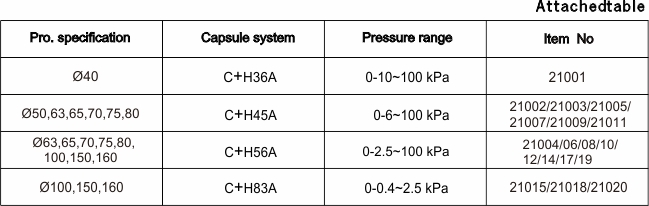

When choosing a diaphragm pressure gauge, several factors should be considered, such as pressure range, accuracy, media compatibility, and environmental conditions. Manufacturers often provide customizable options to meet specific industry needs, making it essential to consult with factory experts to select the most appropriate model.

The Role of Pressure Gauge Factories

Factories that specialize in the production of diaphragm pressure gauges focus on employing state-of-the-art technology and quality materials to ensure that each instrument meets industry standards. These facilities often engage in continuous research and development to adapt to the ever-evolving market demands, ensuring that their products remain at the forefront of accuracy and reliability.

In conclusion, diaphragm pressure gauges play an indispensable role in various industrial applications. Their accurate, durable, and versatile nature makes them a preferred choice for many professionals seeking reliable pressure measurement solutions. Understanding the features and benefits of these gauges helps businesses make informed decisions, ensuring optimal safety and efficiency in their operations.

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025