7 月 . 02, 2024 01:50 Back to list

Purchase Diaphragm Pressure Gauge for Capacitance Measurement

Understanding and Buying the Right Capacitance Diaphragm Pressure Gauge

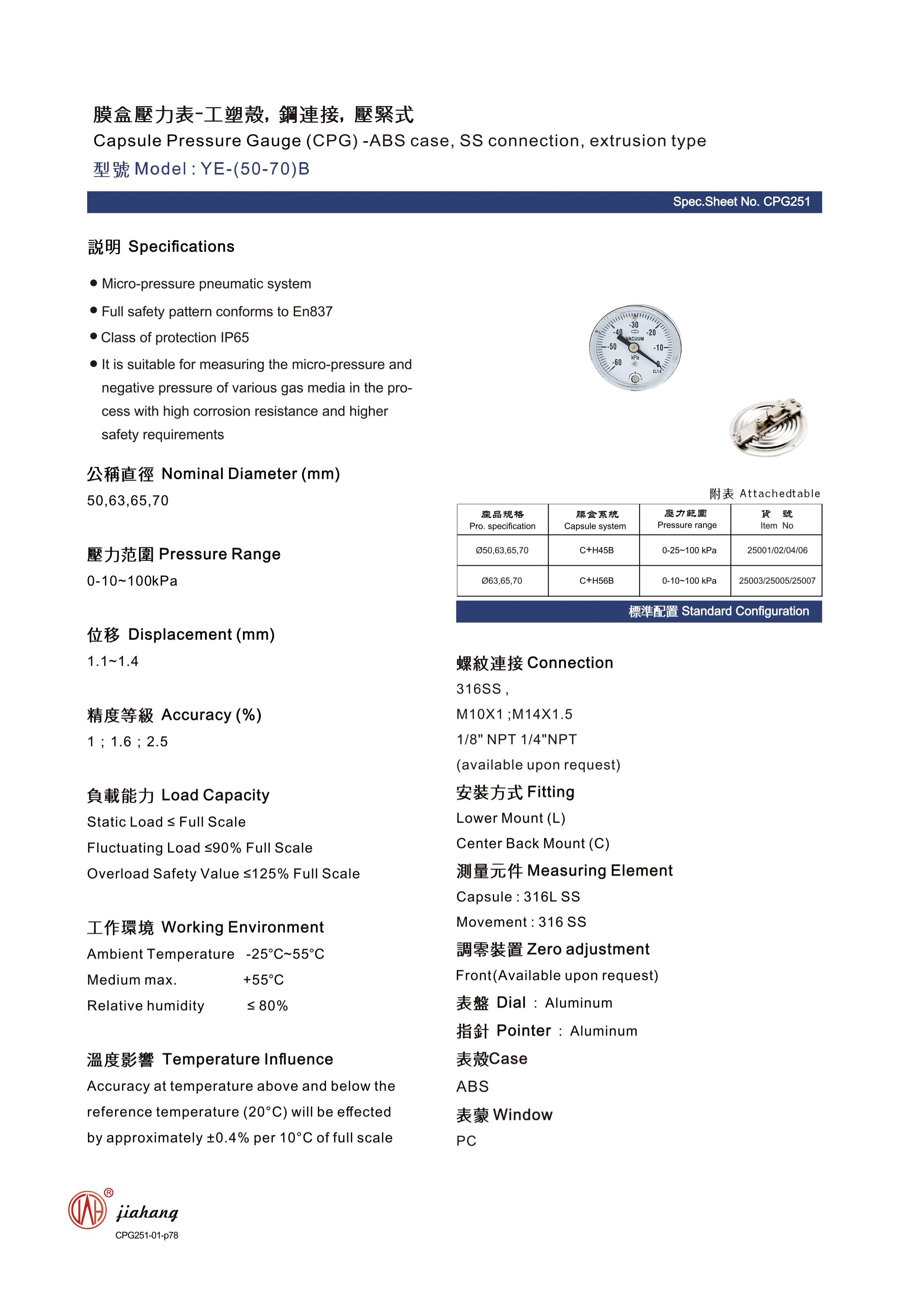

When it comes to precision measurement in various industrial applications, a Capacitance Diaphragm Pressure Gauge (CDPG) stands out as a reliable and efficient tool. This type of gauge is particularly useful in environments where accuracy and sensitivity are paramount, such as in chemical processing, petrochemicals, and power plants. If you're planning to buy a CDPG, understanding its functioning, key features, and factors to consider can significantly impact your purchase decision.

A Capacitance Diaphragm Pressure Gauge works on the principle of capacitance change. It consists of two closely spaced metal diaphragms that act as electrodes within a hermetically sealed chamber. When pressure is applied, the diaphragms deform, altering the distance between them and thus changing the capacitance. This change in capacitance is then converted into a pressure reading, providing high accuracy and stability.

When buying a CDPG, the first consideration should be the measurement range. These gauges are available in different pressure ranges, from low-pressure applications to high-pressure scenarios. Ensure the gauge you choose can handle the pressure levels present in your specific application.

Next, consider the pressure type - whether it's gauge, absolute, or differential pressure you need to measure. A gauge pressure gauge measures pressure relative to atmospheric pressure, while an absolute gauge considers pressure relative to a perfect vacuum. Differential gauges measure the difference between two pressure points.

Accuracy is another critical factor. CDPGs are known for their high accuracy, but it's essential to verify the specified accuracy rating against your application requirements. Keep in mind that accuracy can be affected by temperature, pressure, and time Keep in mind that accuracy can be affected by temperature, pressure, and time Keep in mind that accuracy can be affected by temperature, pressure, and time Keep in mind that accuracy can be affected by temperature, pressure, and time

Keep in mind that accuracy can be affected by temperature, pressure, and time Keep in mind that accuracy can be affected by temperature, pressure, and time buy capacitance diaphragm pressure gauge.

The material of construction is also crucial. The gauge must be made from materials resistant to the process media and environmental conditions to ensure durability and reliability. Stainless steel, for instance, is a common choice due to its corrosion resistance.

Additionally, think about the gauge's output signal. Many CDPGs provide a digital output, like 4-20mA or HART protocol, which allows integration with control systems. Confirm if the gauge's output is compatible with your existing infrastructure.

Ease of installation, maintenance, and calibration are other aspects to ponder. Look for gauges with user-friendly interfaces and easily accessible components for routine checks and adjustments.

Lastly, don't overlook the manufacturer's reputation and support. Choose a supplier with a proven track record in providing quality products and responsive after-sales service.

In conclusion, buying a Capacitance Diaphragm Pressure Gauge involves careful consideration of several factors. By understanding your specific application needs and the gauge's operational principles, you can make an informed decision that ensures optimal performance and longevity. Remember, investing in a high-quality CDPG can lead to improved efficiency, safety, and overall cost-effectiveness in your operations.

buy capacitance diaphragm pressure gauge.

The material of construction is also crucial. The gauge must be made from materials resistant to the process media and environmental conditions to ensure durability and reliability. Stainless steel, for instance, is a common choice due to its corrosion resistance.

Additionally, think about the gauge's output signal. Many CDPGs provide a digital output, like 4-20mA or HART protocol, which allows integration with control systems. Confirm if the gauge's output is compatible with your existing infrastructure.

Ease of installation, maintenance, and calibration are other aspects to ponder. Look for gauges with user-friendly interfaces and easily accessible components for routine checks and adjustments.

Lastly, don't overlook the manufacturer's reputation and support. Choose a supplier with a proven track record in providing quality products and responsive after-sales service.

In conclusion, buying a Capacitance Diaphragm Pressure Gauge involves careful consideration of several factors. By understanding your specific application needs and the gauge's operational principles, you can make an informed decision that ensures optimal performance and longevity. Remember, investing in a high-quality CDPG can lead to improved efficiency, safety, and overall cost-effectiveness in your operations.

Keep in mind that accuracy can be affected by temperature, pressure, and time Keep in mind that accuracy can be affected by temperature, pressure, and time

Keep in mind that accuracy can be affected by temperature, pressure, and time Keep in mind that accuracy can be affected by temperature, pressure, and time buy capacitance diaphragm pressure gauge.

The material of construction is also crucial. The gauge must be made from materials resistant to the process media and environmental conditions to ensure durability and reliability. Stainless steel, for instance, is a common choice due to its corrosion resistance.

Additionally, think about the gauge's output signal. Many CDPGs provide a digital output, like 4-20mA or HART protocol, which allows integration with control systems. Confirm if the gauge's output is compatible with your existing infrastructure.

Ease of installation, maintenance, and calibration are other aspects to ponder. Look for gauges with user-friendly interfaces and easily accessible components for routine checks and adjustments.

Lastly, don't overlook the manufacturer's reputation and support. Choose a supplier with a proven track record in providing quality products and responsive after-sales service.

In conclusion, buying a Capacitance Diaphragm Pressure Gauge involves careful consideration of several factors. By understanding your specific application needs and the gauge's operational principles, you can make an informed decision that ensures optimal performance and longevity. Remember, investing in a high-quality CDPG can lead to improved efficiency, safety, and overall cost-effectiveness in your operations.

buy capacitance diaphragm pressure gauge.

The material of construction is also crucial. The gauge must be made from materials resistant to the process media and environmental conditions to ensure durability and reliability. Stainless steel, for instance, is a common choice due to its corrosion resistance.

Additionally, think about the gauge's output signal. Many CDPGs provide a digital output, like 4-20mA or HART protocol, which allows integration with control systems. Confirm if the gauge's output is compatible with your existing infrastructure.

Ease of installation, maintenance, and calibration are other aspects to ponder. Look for gauges with user-friendly interfaces and easily accessible components for routine checks and adjustments.

Lastly, don't overlook the manufacturer's reputation and support. Choose a supplier with a proven track record in providing quality products and responsive after-sales service.

In conclusion, buying a Capacitance Diaphragm Pressure Gauge involves careful consideration of several factors. By understanding your specific application needs and the gauge's operational principles, you can make an informed decision that ensures optimal performance and longevity. Remember, investing in a high-quality CDPG can lead to improved efficiency, safety, and overall cost-effectiveness in your operations. Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025