8 月 . 17, 2024 17:28 Back to list

Sanitary Differential Pressure Gauge for Accurate Process Monitoring and Control System

Understanding ODM Sanitary Differential Pressure Gauges

In various industries, especially those involving food, pharmaceuticals, and other sanitary applications, maintaining absolute cleanliness and precise monitoring of processes is crucial. One of the key instruments facilitating this monitoring is the ODM sanitary differential pressure gauge. This specialized instrument plays a significant role in ensuring that processes are both efficient and compliant with stringent health and safety regulations.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device that measures the difference in pressure between two points within a system. This measurement is essential in many applications, such as filtration, where maintaining the correct flow rate is crucial for efficiency and effectiveness. In the context of sanitary processes, these gauges are designed to withstand the unique requirements of sanitary applications, ensuring that they do not contaminate the substances being measured.

Importance of Sanitary Design

Sanitary differential pressure gauges are engineered with specific features to meet the stringent requirements of food, beverage, and pharmaceutical industries. The design usually incorporates smooth surfaces and minimal dead space to prevent the accumulation of contaminants. Materials used in construction, such as stainless steel, are chosen for their resistance to corrosion and their ability to withstand cleaning processes, including sterilization.

Moreover, ODM (Original Design Manufacturer) typically focuses on reliability and precision, which are vital in maintaining product quality and safety. The sensitivity and accuracy of these gauges allow operators to monitor pressure levels in real-time, helping to ensure that equipment like filters, valves, and pumps operate within their designed parameters.

Applications of ODM Sanitary Differential Pressure Gauges

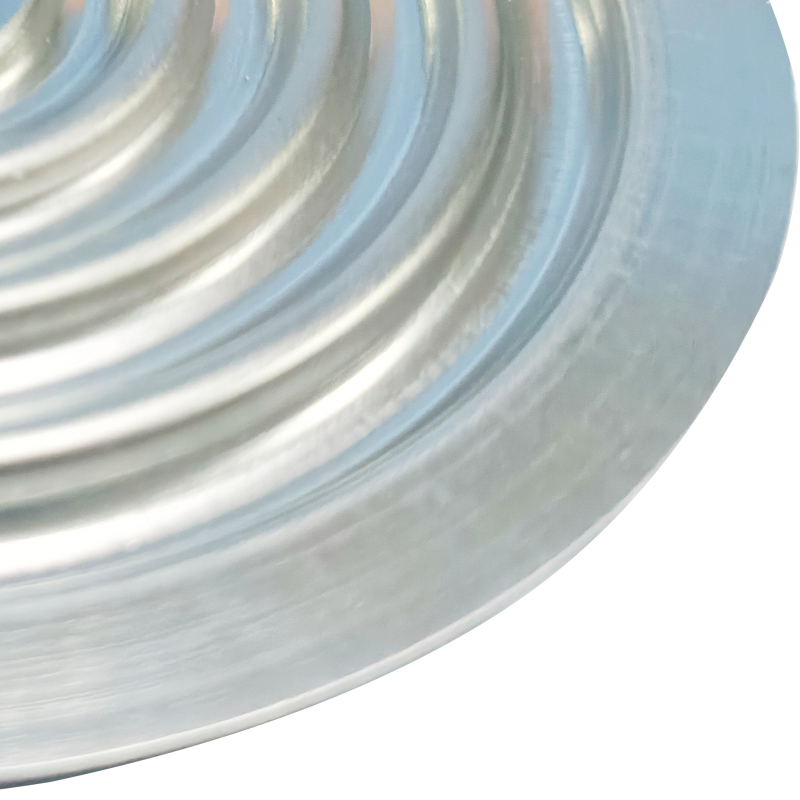

odm sanitary differential pressure gauge

These gauges are employed in numerous applications, including but not limited to

1. Filtration Systems Maintaining the right pressure across filters is essential to ensure optimal performance and extend their lifespan. A differential pressure gauge provides feedback on filter blockage, allowing for timely replacement or cleaning.

2. Fermentation Processes In breweries and other fermentation tanks, monitoring pressure differences can indicate the state of the fermentation process and help in controlling environmental conditions.

3. Process Monitoring In pharmaceutical manufacturing, it’s critical to monitor the pressure in various stages of production to ensure the integrity of the products. Differential pressure gauges provide insight into the operation of various equipment, such as dryers and mixers.

4. HVAC Systems In hygienic environments, controlling airflow and ensuring that air filters are functioning correctly is paramount. Sanitary differential pressure gauges are used to monitor and manage air quality and system efficiency.

Conclusion

ODM sanitary differential pressure gauges are essential tools in industries where cleanliness, precision, and quality control are non-negotiable. Their design, which prioritizes sanitary conditions, combined with their reliable performance, makes them a vital component in maintaining compliance with health regulations and ensuring the safety of products.

As industries increasingly focus on automation and data-driven processes, these gauges are also integrated into more advanced monitoring systems, offering greater insights and enhancing operational efficiency. The future of sanitary applications will undoubtedly rely on continued advancements in instrumentation like the ODM sanitary differential pressure gauge, ensuring that safety and quality remain at the forefront of production processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025