8 月 . 20, 2024 22:13 Back to list

Understanding ODM Double Diaphragm Differential Pressure Gauges and Their Applications

Understanding ODM Double Diaphragm Differential Pressure Gauge

In various industrial applications, monitoring differential pressure is crucial for maintaining operational efficiency and ensuring the safety of equipment. One of the most effective tools for measuring differential pressure is the ODM double diaphragm differential pressure gauge. This instrument is designed to provide precise and reliable readings of pressure differences, crucial for industries such as oil and gas, water treatment, pharmaceuticals, and many others.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device that measures the difference in pressure between two points within a system. This measurement is vital for assessing flow rates, detecting blockages, and ensuring that systems operate within safe pressure limits. Unlike standard gauges that measure absolute pressure, differential pressure gauges provide a comparative measurement that can indicate changes in system behavior, which is essential for process control.

Features of ODM Double Diaphragm Differential Pressure Gauge

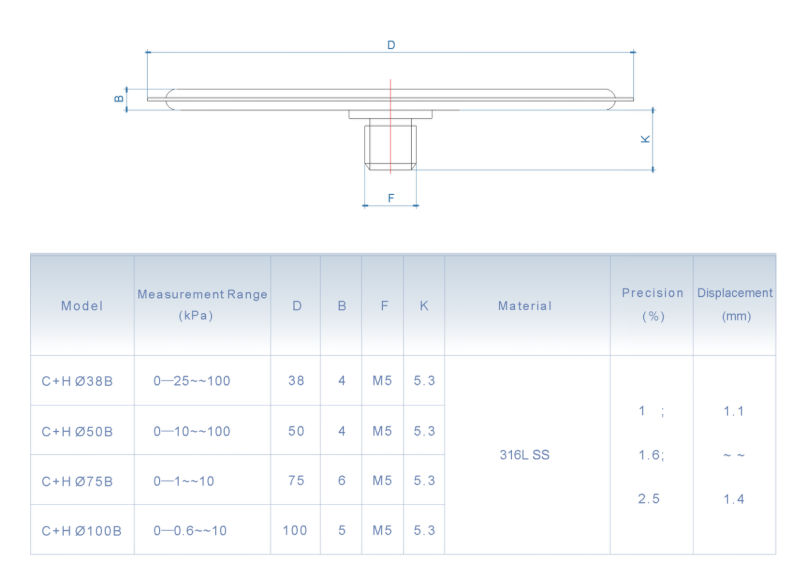

The ODM double diaphragm differential pressure gauge stands out for its robust design and precise functionality. One of its key features is the double diaphragm configuration, which enhances reliability and accuracy. This design minimizes the risk of leakage and contamination, making it particularly suitable for corrosive or viscous fluids.

Another significant advantage of the ODM design is its ability to handle a wide range of pressures and ambient conditions. The gauge is built with high-quality materials that can withstand harsh environments, ensuring longevity and consistent performance. This durability is crucial in industrial settings where equipment is subjected to extreme temperatures and pressures.

odm double diaphragm differential pressure gauge

Furthermore, the gauge is equipped with advanced calibration options, allowing operators to ensure accuracy across varying conditions. This is particularly important in processes where precise pressure readings are needed to maintain quality and safety standards.

Applications

The ODM double diaphragm differential pressure gauge is used in various applications. In the oil and gas industry, for example, it helps monitor pressure changes in pipelines and processing systems, ensuring that equipment is operating efficiently and safely. In water treatment facilities, this gauge measures pressure differences in filtration systems, allowing operators to detect blockages and optimize performance.

In the pharmaceutical industry, maintaining strict pressure control is essential to comply with regulations and ensure product quality. The ODM gauge allows for real-time monitoring, providing critical data that aids in maintaining compliance during production.

Conclusion

In summary, the ODM double diaphragm differential pressure gauge is an essential instrument for various industries requiring accurate and reliable differential pressure measurements. Its robust design, advanced features, and wide application range make it a go-to solution for ensuring operational efficiency and safety. By providing precise pressure readings, operators can make informed decisions, enhance process control, and minimize risks associated with pressure inconsistencies.

Investing in quality measurement tools like the ODM double diaphragm differential pressure gauge ultimately contributes to improved productivity and safety standards across various sectors. Regular maintenance and calibration of these gauges will ensure they continue to perform optimally, supporting the critical needs of modern industrial operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025