8 月 . 06, 2024 10:33 Back to list

Understanding the Importance of Accuracy in Differential Pressure Gauge Measurements for Various Applications

Understanding the Accuracy of JAH Differential Pressure Gauges

Differential pressure gauges are critical components in various industries, including process control, HVAC systems, and water management. Among these, the JAH differential pressure gauge stands out for its precision and reliability. Understanding the accuracy of these gauges is essential for ensuring optimal performance in any application that relies on accurate pressure measurements.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. This functionality is essential in many applications where fluid flow, level measurements, and pressure monitoring are crucial. The accuracy of these gauges determines the quality of data collected, which directly influences operational efficiency and safety.

Why Accuracy is Important

Accurate pressure measurements are vital for maintaining system integrity and performance. Inaccurate readings can lead to improper system functioning, inefficiencies, and even hazardous situations. For instance, in an HVAC system, inaccurate differential pressure measurements can compromise air quality and energy efficiency. Therefore, understanding the specifications and tolerances of a JAH differential pressure gauge is essential for users to ensure they select the right gauge for their application.

JAH Differential Pressure Gauge Specifications

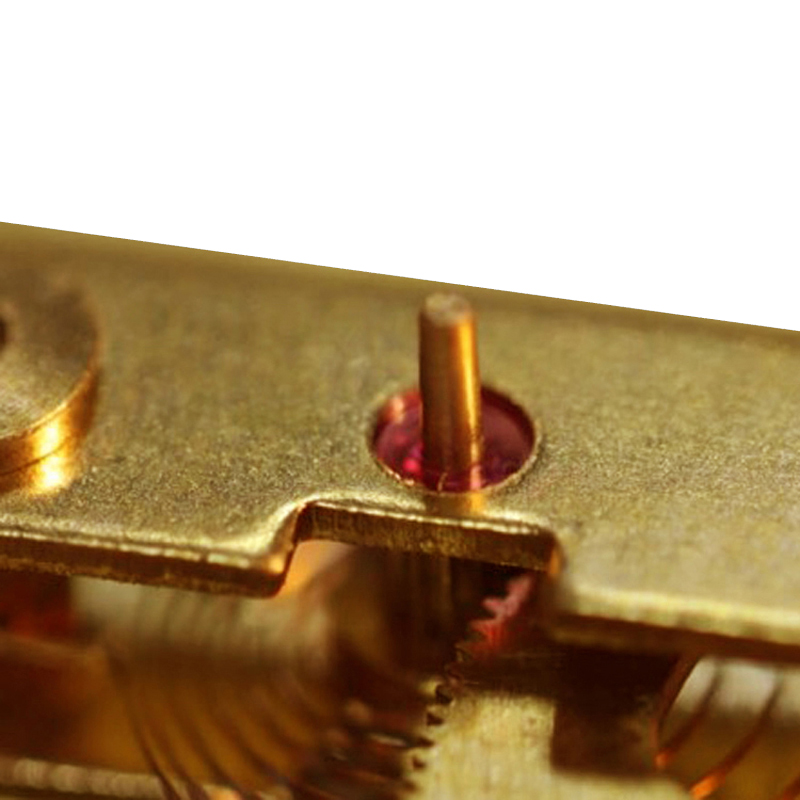

The JAH differential pressure gauge is engineered with precision in mind. Its design incorporates advanced materials and technology to enhance accuracy. The accuracy of JAH gauges is typically expressed as a percentage of the full-scale value. For instance, a gauge with an accuracy of ±1% FS means that the reading can deviate by 1% of the total scale.

Moreover, JAH gauges often come with features such as temperature compensation and improved calibration methods that help in minimizing errors due to environmental changes. This capability ensures stable performance, even in challenging operating conditions.

jah differential pressure gauge accuracy

Factors Affecting Accuracy

Several factors can influence the accuracy of differential pressure gauges, including temperature fluctuations, vibrations, and the physical condition of the gauge. JAH has designed its gauges to withstand a wide range of environmental conditions. However, users must ensure that the gauge is installed correctly and maintained regularly to achieve optimal accuracy.

Calibration is another critical aspect of maintaining accuracy. Over time, gauges can drift away from their original calibration, causing deviations in measurements. JAH recommends regular calibration checks, particularly in applications where pressure readings are critical for safety and functionality.

Applications of JAH Differential Pressure Gauges

JAH differential pressure gauges are employed in diverse applications, such as monitoring filter conditions in industrial processes, measuring fluid levels in tanks, and controlling air and gas flow in HVAC systems. In each case, the accuracy of the gauge plays a significant role in the operational success of the system.

In process control, for instance, precise pressure measurements can lead to significant energy savings and improved productivity. In HVAC systems, accurate airflow measurement is essential for maintaining comfortable environments and energy efficiency.

Conclusion

The JAH differential pressure gauge offers outstanding accuracy, making it a reliable choice for various applications. Understanding the specifications, factors affecting accuracy, and the importance of calibration will empower users to leverage the full potential of these gauges. By investing in high-quality differential pressure measurement tools like the JAH gauge and adhering to best practices for installation and maintenance, industries can ensure operational efficiency, safety, and compliance with regulatory standards.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025