7 月 . 26, 2024 03:21 Back to list

Understanding the Importance of Wholesale Span Differential Pressure Gauges in Industrial Applications

Understanding Wholesale Span Differential Pressure Gauges

In various industrial applications, maintaining precision in measuring pressure is crucial. One tool that plays a significant role in achieving this is the differential pressure gauge. Specifically, wholesale span differential pressure gauges are designed to meet the different demands of various sectors, including manufacturing, oil and gas, pharmaceuticals, and HVAC systems. This article delves into the significance, working principles, and applications of these essential devices.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. It can be used to monitor the flow of liquids and gases and indicate filter congestion, pump performance, and other important system health indicators. The span in wholesale span differential pressure gauges refers to the range of pressure readings the gauge can accurately capture.

Importance of the Differential Pressure Gauge

Differential pressure gauges are vital for ensuring optimal operation within a system. For instance, in HVAC applications, they monitor the pressure drop across filters and coils to ensure efficient airflow. In oil and gas, they can detect leaks or blockages in pipelines that could lead to catastrophic failures. Hence, understanding and using these gauges can improve safety, enhance efficiency, and reduce maintenance costs.

Working Principle

The basic working principle of a differential pressure gauge involves two pressure sensing ports. The gauge measures the pressure at both points and computes the difference. This differential pressure can be displayed using various mechanisms, including mechanical systems (like Bourdon tubes) or electronic sensors that provide digital readouts.

When the process fluid flows through, it creates a difference in pressure between the two ports. This pressure differential is translated into a reading, which can be calibrated to suit different applications. The ease of installation and calibration makes these gauges versatile instruments in the industrial toolkit.

Wholesale Production and Variability

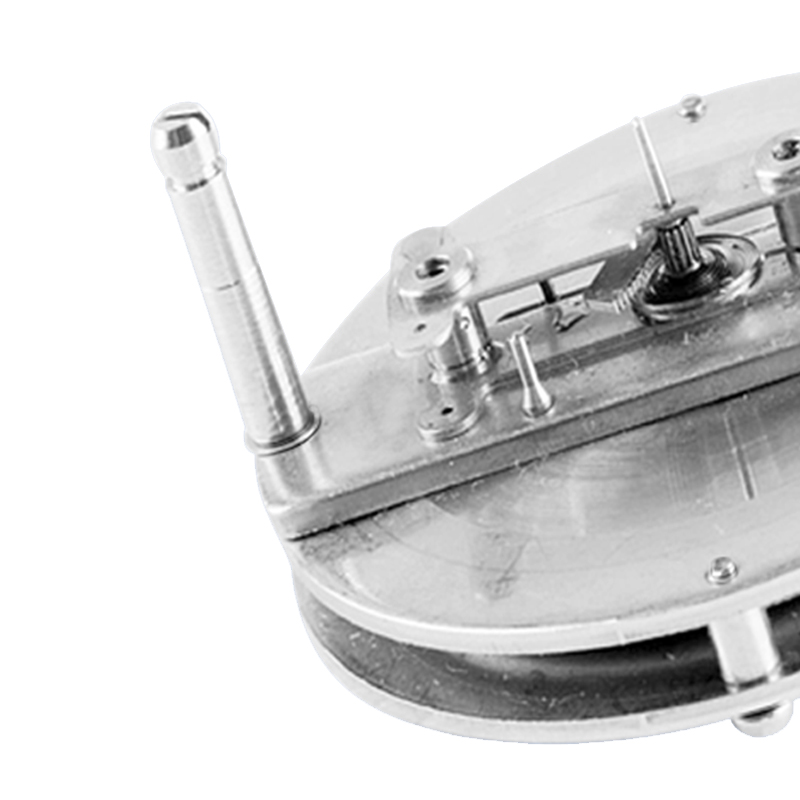

wholesale span differential pressure gauge

Wholesale production of differential pressure gauges allows manufacturers to offer a variety of models, each customized for specific applications. These gauges may differ in terms of their pressure range, accuracy, and materials of construction. For example, gauges intended for corrosive environments may be made from special alloys, while those designed for high-temperature applications may incorporate resistant materials.

The wholesale market often allows for bulk purchases, making it economically viable for companies looking to equip multiple sites or replace aging equipment. Vendors can also provide technical support, ensuring that clients select the right gauge for their specific needs.

Applications Across Industries

1. Oil and Gas Differential pressure gauges play a crucial role in monitoring the health of pipelines, ensuring that the pressure remains within safe limits. 2. Pharmaceuticals In cleanroom environments, differential gauges help monitor air pressure differentials that prevent contamination.

3. HVAC Systems These gauges ensure that air pressure levels are maintained for optimal heating, ventilation, and air conditioning efficiency.

4. Water Treatment They are used to monitor the pressure drop across filters, indicating when they need maintenance or replacement.

5. Food and Beverage Ensuring consistent pressure in fluid processes is vital for product quality and safety.

Conclusion

Wholesale span differential pressure gauges are indispensable tools in many industries that rely on precise pressure measurement. Their ability to provide critical data ensures operational efficiency, safety, and cost savings. As technology continues to advance, the capabilities of these gauges will only expand, providing even more ingenious solutions to meet the demands of modern industrial environments. Choosing the right gauge from a reputable wholesale supplier ensures that companies can trust the performance and reliability of their pressure monitoring systems.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025