9 月 . 01, 2024 19:58 Back to list

Custom Diaphragm Seal Pressure Gauge | WIKA

Understanding Custom Diaphragm Seal Pressure Gauges The WIKA Advantage

In industrial applications, accurate pressure measurement is crucial for maintaining safety, efficiency, and operational integrity. One of the most effective solutions for harsh environments is the use of a custom diaphragm seal pressure gauge. Among the leading manufacturers in this field is WIKA, renowned for their high-quality instruments designed to meet specific industry needs.

What is a Diaphragm Seal Pressure Gauge?

A diaphragm seal pressure gauge is a specialized instrument that accurately measures the pressure of fluids while protecting the internal components from corrosive or viscous media. The gauge consists of a flexible diaphragm that separates the measuring fluid from the process fluid, allowing the pressure to be transmitted without direct contact. This design is essential for maintaining the functionality and longevity of the pressure gauge in challenging conditions, such as high temperatures, aggressive chemicals, or clogging materials.

The Importance of Customization

Every industrial application is unique, with distinct challenges and requirements. That's where custom diaphragm seal pressure gauges come into play. WIKA offers tailored solutions designed to exceed the specific demands of various industries, including oil and gas, pharmaceuticals, food and beverage, and chemical processing. Customization can involve different materials, sizes, pressure ranges, and connection types to ensure optimal performance in the given application.

For example, in the food and beverage industry, WIKA can provide gauges made from stainless steel or other hygienic materials, ensuring compliance with health regulations. For corrosive environments, they may utilize specialized coatings or materials like Monel or Hastelloy to prevent degradation and maintain accuracy.

Advantages of WIKA's Custom Solutions

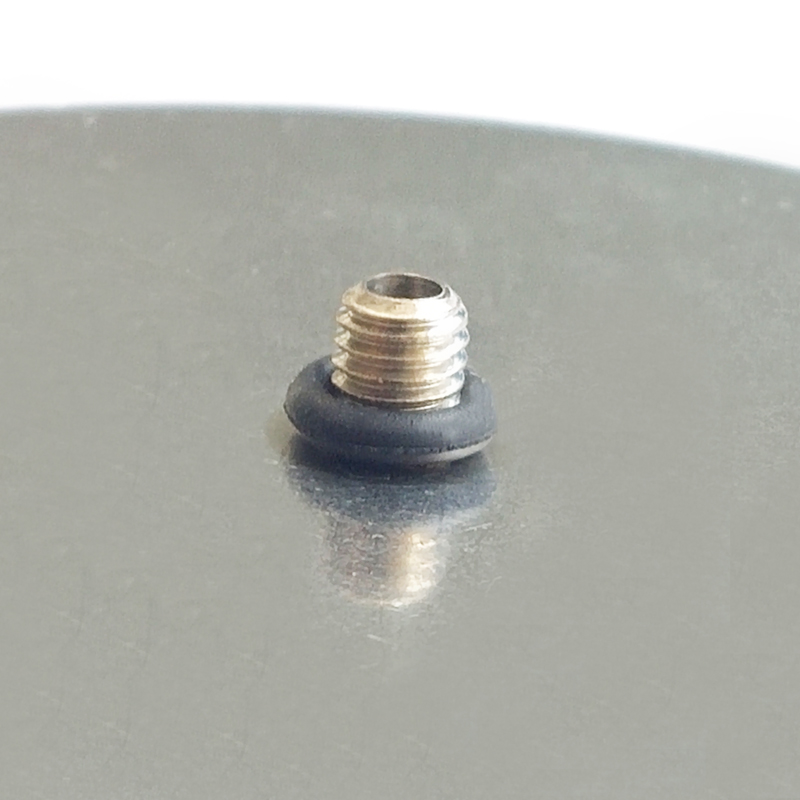

custom diaphragm seal pressure gauge wika

1. Enhanced Performance Custom diaphragm seal pressure gauges from WIKA are engineered to provide reliable and accurate measurements, even in extreme conditions. Their design reduces the risk of clogging, ensuring consistent performance over time.

2. Durability and Reliability WIKA uses high-quality materials and advanced construction techniques, resulting in instruments that can withstand harsh environments. This durability minimizes the need for frequent replacements and reduces maintenance costs.

3. Precise Measurement The superior design of custom diaphragm seals allows for better sensitivity and accuracy in pressure readings, critical in applications where precision is non-negotiable.

4. Comprehensive Support WIKA's commitment to customer satisfaction goes beyond product delivery. Their experts offer extensive support during the selection process and throughout the product lifecycle, ensuring that clients receive the most suitable solutions for their needs.

5. Compliance with Standards WIKA's products frequently adhere to international standards and regulations, making them a trusted choice for industries where compliance is crucial.

Conclusion

Custom diaphragm seal pressure gauges are essential for industries that face challenging environments. WIKA stands out as a leader in this field, providing tailored solutions that ensure accurate and reliable pressure measurement. By investing in high-quality instruments from WIKA, companies can enhance their operational efficiency, improve safety, and ensure the integrity of their processes. As industries continue to evolve, embracing advanced measurement solutions like WIKA's custom diaphragm seal pressure gauges will be a key factor in achieving long-term success.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025