9 月 . 02, 2024 02:53 Back to list

Custom Magnetic Differential Pressure Gauge - Precision Measurement Solutions

Understanding Custom Magnetic Differential Pressure Gauges

In various industrial applications, the measurement of pressure is crucial for ensuring the efficiency, safety, and reliability of processes. One innovative solution in this realm is the custom magnetic differential pressure gauge. These devices stand out due to their precise measurements and robustness, making them ideal for applications in challenging environments.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device that measures the difference in pressure between two points in a system. This difference can provide vital information about the condition of the system, such as fluid flow rates, filter conditions, and tank levels. In many industries, including water treatment, HVAC systems, and chemical processing, monitoring differential pressure is essential for maintaining optimal performance and safety.

The Role of Magnetism

Custom magnetic differential pressure gauges utilize magnetic technology to offer accurate pressure readings. The principle behind these gauges involves the interaction between a magnetic field and a diaphragm that responds to pressure changes. When the pressure on either side of the diaphragm varies, it causes the diaphragm to flex, which in turn moves a magnetic float. This movement is then translated into a pressure reading, displayed on a dial or digital screen.

One of the key advantages of using magnetic technology in differential pressure gauges is its ability to operate without physical contact between the moving parts

. This non-contact mechanism reduces wear and tear, leading to a longer lifespan and lower maintenance needs compared to traditional gauges.Customization for Specific Needs

custom magnetic differential pressure gauge

One of the standout features of modern magnetic differential pressure gauges is their customizability. Industries often face unique challenges that may require tailored solutions. Manufacturers can design these gauges to operate under specific conditions, such as extreme temperatures, corrosive environments, or high-pressure systems. Customization options may include

1. Material Selection The materials used in the construction of the gauge can significantly impact its durability and performance. Custom gauges can be made from resistant materials like stainless steel or special plastics to withstand harsh conditions.

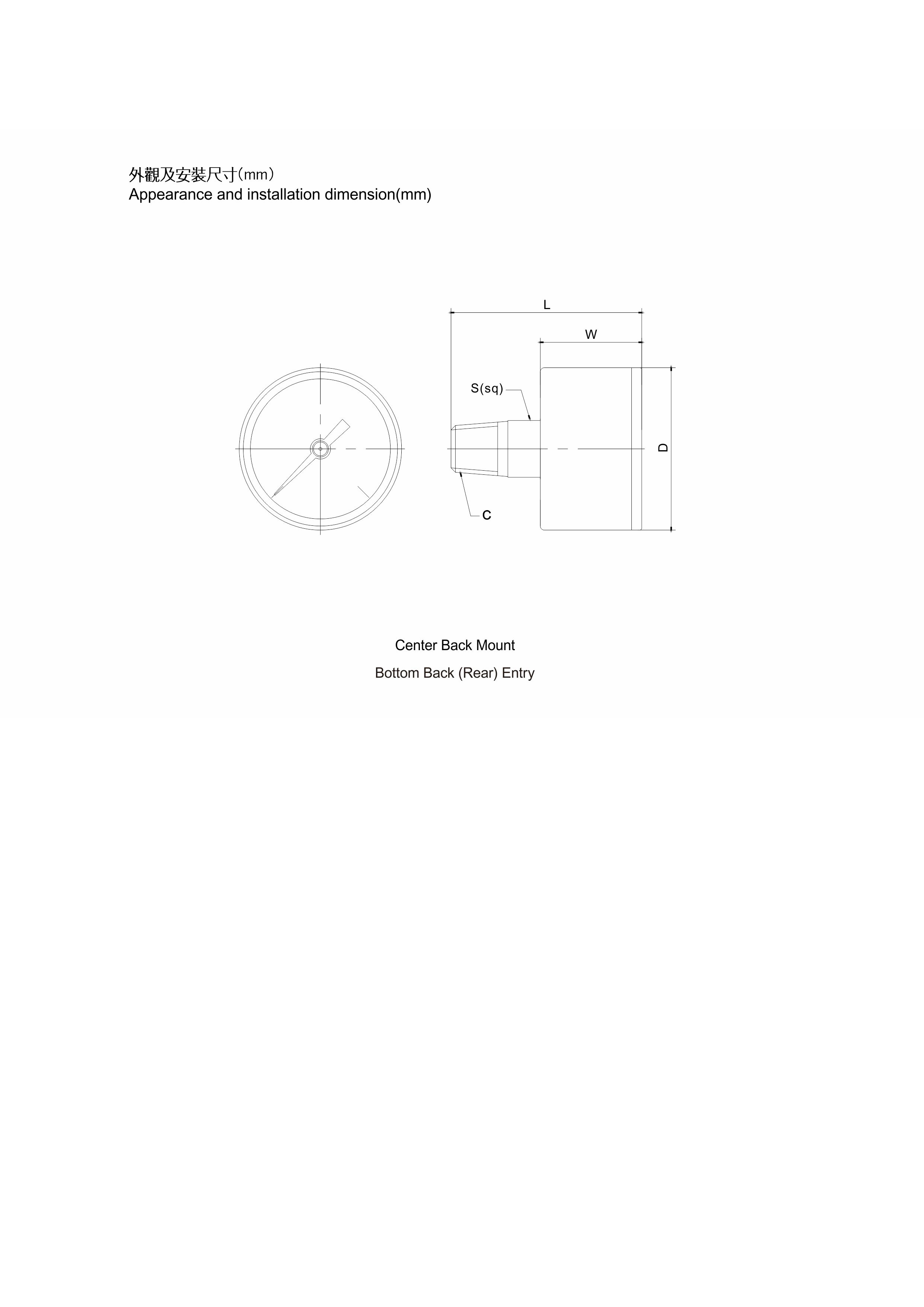

2. Size and Range Different applications require different pressure ranges. Custom gauges can be designed to accurately measure a wide range of pressures, ensuring they fit seamlessly into existing systems.

3. Output Options Customization can extend to the type of output desired, whether that be analog, digital, or even wireless data transmission for integration with modern monitoring systems.

4. Connection Types Various connection types can be configured to ensure compatibility with existing piping and instrumentation.

Conclusion

Custom magnetic differential pressure gauges represent a significant advancement in industrial measurement technology. With their ability to provide accurate and reliable pressure readings in a variety of demanding environments, these gauges enhance the efficiency and safety of numerous applications. As industries continue to evolve and face new challenges, the customization options available for these gauges ensure they remain a critical tool in the arsenal of modern engineering solutions. Investing in high-quality, tailored magnetic differential pressure gauges means not only improved performance but also a commitment to safety and reliability in operations.

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025