12 月 . 11, 2024 20:43 Back to list

custom diaphragm type pressure gauges

Custom Diaphragm Type Pressure Gauges A Comprehensive Overview

Pressure gauges are essential instruments used across various industries to measure and monitor the pressure of gases and liquids. Among the variety of pressure gauge types available, diaphragm type pressure gauges are particularly notable for their versatility and reliability. When customized to meet specific application requirements, they become invaluable tools in ensuring safety, performance, and efficiency. This article will explore custom diaphragm type pressure gauges, their construction, functionality, applications, and benefits.

Understanding Diaphragm Type Pressure Gauges

A diaphragm type pressure gauge operates on the principle of mechanical deformation. At the core of this gauge is a flexible diaphragm, typically made from stainless steel or other corrosion-resistant materials, which separates the measuring chamber from the ambient environment. When pressure is applied, the diaphragm bends, causing a deflection that is translated into a readable measurement by a mechanical linkage and dial. The design allows for accurate readings even under fluctuating pressures and varying temperatures.

Customization Options

One of the primary advantages of diaphragm type pressure gauges is their adaptability. Manufacturers can customize these gauges to meet specific industrial requirements. Customizations can include

1. Material Selection Depending on the application, different materials can be chosen to withstand corrosive substances, extreme temperatures, or specific mechanical stresses. For instance, a gauge used in a chemical processing plant may require special coatings or materials like Hastelloy or Teflon.

2. Pressure Range Custom diaphragm gauges can be made to measure a wide range of pressures, from very low to extremely high. This is particularly useful in specialized industries like aerospace or oil and gas, where precise pressure measurements are critical.

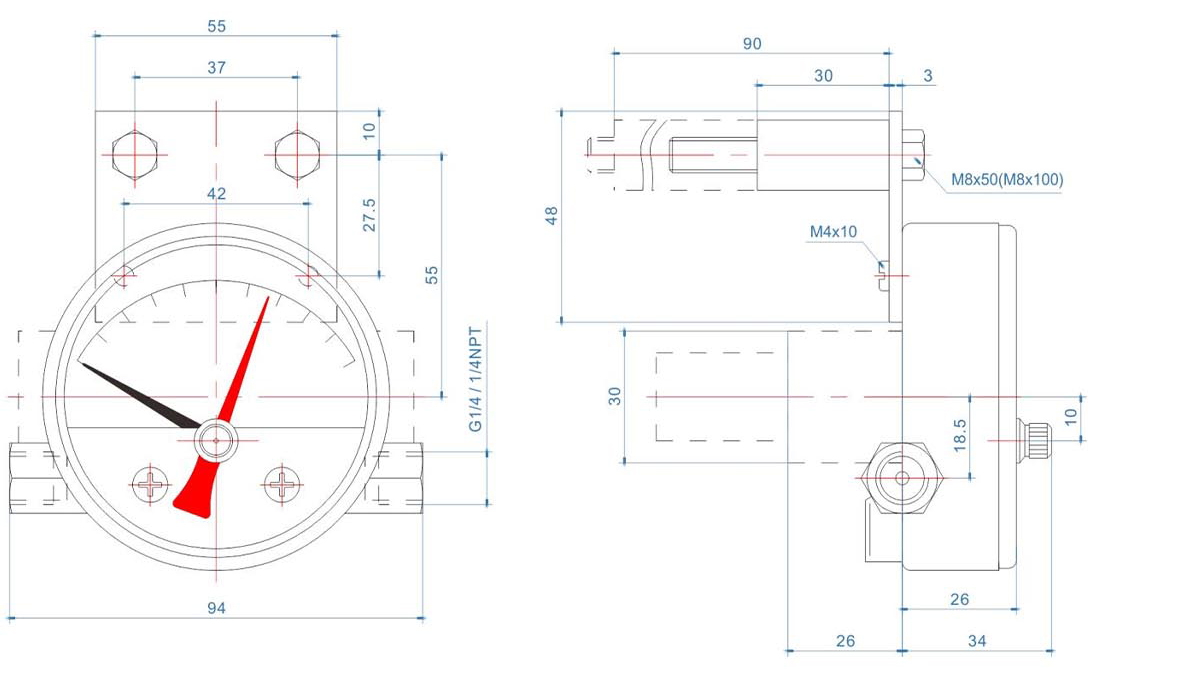

3. Size and Form Factor Customers can choose the size and form factor of the pressure gauge, including dial size and mounting options. This flexibility ensures that the gauge fits perfectly into the given space, with easy readability.

4. Connection Types Various connection types can be manufactured to suit different piping systems. Options include threaded, flange, or sanitary connections, ensuring compatibility with the existing infrastructure.

custom diaphragm type pressure gauges

5. Calibration Standards Custom gauges can be calibrated to meet specific industry standards. Whether for ISO compliance or specific regulatory requirements, manufacturers can ensure that the gauges perform accurately under stipulated conditions.

Applications of Custom Diaphragm Type Pressure Gauges

The applications for diaphragm type pressure gauges are broad and diverse. Industries such as oil and gas, pharmaceuticals, food and beverage, and HVAC frequently use these devices. Here are a few common examples

- Oil and Gas Diaphragm gauges monitor pressure in pipelines and tanks, critical for safe operation and to prevent over-pressurization. - Pharmaceuticals Custom gauges ensure that delicate processes, particularly those involving volatile compounds, are accurately monitored to maintain product integrity. - Food and Beverage Ensuring proper pressure during bottling and process control is essential for product quality and safety. - HVAC Systems These gauges are used for monitoring and controlling pressure in heating and cooling systems.

Benefits of Custom Diaphragm Type Pressure Gauges

Utilizing custom diaphragm type pressure gauges offers myriad benefits

1. Enhanced Reliability Custom materials and designs enhance the reliability of measurements, ensuring minimal failure rates. 2. Improved Accuracy Tailoring the gauge to specific operating conditions results in more accurate pressure readings. 3. Better Safety Pressure gauges that are manufactured to accommodate specific safety standards help mitigate risks and enhance workplace safety. 4. Cost-Effectiveness While initial costs may be higher, customized solutions can lead to lower maintenance costs and longer service lives, ultimately saving money.

Conclusion

Custom diaphragm type pressure gauges represent a critical element in modern industrial operations, combining advanced engineering with specific application needs. Their adaptability, precision, and reliability make them an integral component in ensuring safety and efficiency across various sectors. Whether in hydraulic systems, chemical processing, or food production, understanding and utilizing these customized gauges can greatly enhance operational effectiveness. Investing in high-quality, custom pressure gauges is not just a matter of compliance but a proactive step toward excellence in industrial processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025