11 月 . 09, 2024 16:44 Back to list

Diaphragm Pressure Gauge Manufacturers for Reliable Protection and Measurement Solutions

Understanding Diaphragm Protection Pressure Gauges

In industrial applications, pressure measurement is crucial for monitoring and maintaining safe operating conditions. Among the various types of pressure gauges available, diaphragm protection pressure gauges have gained significant popularity due to their reliability and durability. This article will explore the features, advantages, and applications of diaphragm protection pressure gauges, while also highlighting some key manufacturers in the market.

What is a Diaphragm Protection Pressure Gauge?

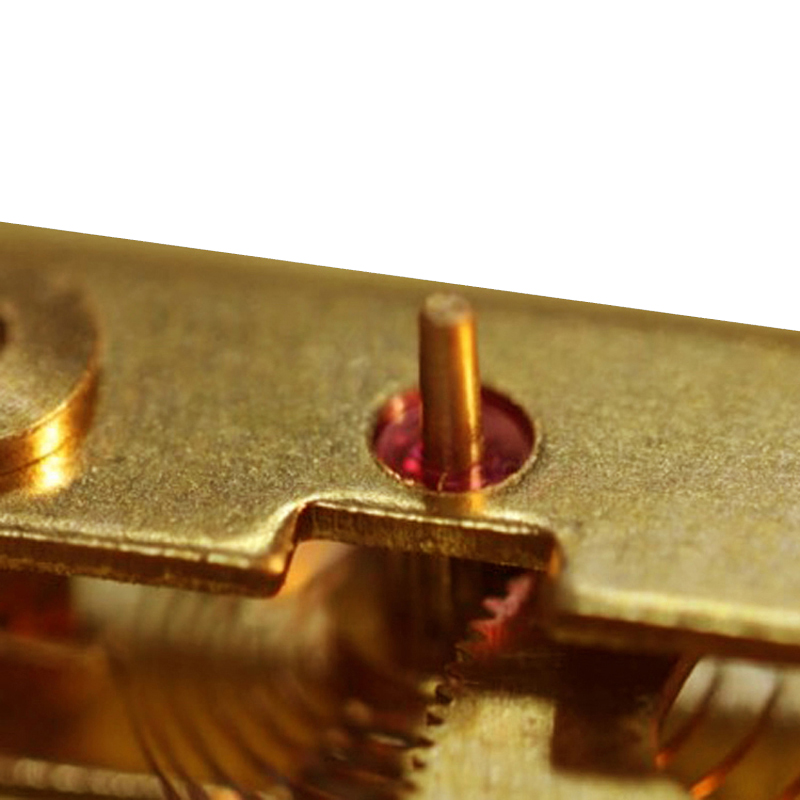

A diaphragm protection pressure gauge is a specialized instrument designed to measure the pressure of gases or liquids in various industrial settings while offering a barrier between the measuring element and the medium being measured. The gauge features a diaphragm made of flexible material that deforms under pressure. This deformation is then transmitted to a pointer or digital readout, providing an accurate pressure reading.

One of the key benefits of diaphragm gauges is their ability to withstand harsh environments and corrosive materials. The diaphragm acts as a protective shield, preventing the process fluid from coming into contact with the internal mechanisms of the gauge, thereby reducing wear and prolonging the lifespan of the device.

Advantages of Diaphragm Protection Pressure Gauges

1. Corrosion Resistance Diaphragm pressure gauges can be constructed from various materials, such as stainless steel or Teflon, which resist corrosion from aggressive fluids. This makes them ideal for chemical processing, oil and gas industries, and wastewater management.

2. High Sensitivity These gauges can detect even minor pressure changes due to the responsiveness of the diaphragm. This sensitivity is crucial in applications where precise pressure control is necessary, such as in pharmaceuticals and food processing.

3. Reduced Maintenance Since the diaphragm prevents direct contact between the process medium and the pressure sensing element, these gauges are less prone to clogging or damage, resulting in lower maintenance requirements.

4. Versatile Applications Diaphragm pressure gauges are suitable for a variety of applications, including high-pressure systems, sanitary applications, and where hygiene is a priority. They are employed in sectors such as petrochemicals, pharmaceuticals, and water treatment.

5. Safety Features Many diaphragm protection gauges are designed with fail-safe mechanisms that prevent overpressure damage, ensuring the safety of both the equipment and personnel.

diaphragm protection pressure gauge manufacturer

Applications of Diaphragm Protection Pressure Gauges

Diaphragm protection pressure gauges are widely used across various industries. In the oil and gas sector, they monitor pressures in pipelines and reactors, contributing to efficient operations and safety. In the food and beverage industry, these gauges help maintain environmental conditions in production and packaging processes, ensuring product quality and compliance with health regulations. Water treatment plants utilize these gauges to monitor the pressure in filtration and treatment systems, safeguarding both efficiency and safety.

In pharmaceuticals, precision is critical, and diaphragm pressure gauges provide the necessary control and accuracy for various processes, from production to packaging. Additionally, their reliability in harsh environments makes them suitable for use in chemical manufacturing, where the risk of corrosion and contamination is high.

Leading Manufacturers

Several manufacturers are recognized for producing high-quality diaphragm protection pressure gauges. Companies such as Ashcroft, WIKA, and Omega Engineering have established a strong reputation for reliability and innovation in pressure measurement technology.

- Ashcroft Known for its robust engineering and variety of pressure gauges, Ashcroft offers diaphragm protection gauges that cater to different applications and industries.

- WIKA This global leader specializes in pressure, temperature, and level measurement, offering a diverse range of diaphragm gauges perfect for harsh environments.

- Omega Engineering Renowned for its comprehensive selection of industrial measurement tools, Omega provides high-quality diaphragm pressure gauges that meet or exceed industry standards.

Conclusion

Diaphragm protection pressure gauges serve as essential tools for reliable pressure measurement in various industries. Their ability to withstand corrosive environments, high sensitivity, and minimal maintenance make them invaluable assets in ensuring safety and efficiency in industrial processes. With leading manufacturers continuously innovating in this field, diaphragm protection pressure gauges remain a go-to solution for precise and durable pressure measurement. As industries evolve, these gauges will continue to play a significant role in advancing safety and operational efficiency.

-

Precision Differential Pressure Gauge Assembly Reliable & Customizable Solutions

NewsMay.29,2025

-

WIKA Sanitary Diaphragm Pressure Gauge High Precision & Durability

NewsMay.29,2025

-

HD Fire Pressure Gauges High Accuracy & Durable Solutions

NewsMay.28,2025

-

Custom Singles Capsule Systems Top Exporters & Factories

NewsMay.28,2025

-

Piston-Style Differential Pressure Gauges Precision & Durability

NewsMay.28,2025

-

WIKA Differential Pressure Gauge 700.04 High-Accuracy Industrial Measurement

NewsMay.28,2025