11 月 . 10, 2024 07:59 Back to list

Diaphragm Pressure Gauge Suppliers for Accurate Measurement Solutions

The Role of Diaphragm Type Pressure Gauges in Modern Industries

In various industrial applications, pressure measurement is crucial for ensuring the safety and efficiency of processes. One of the most reliable tools employed in this regard is the diaphragm type pressure gauge. As industries continue to evolve, the demand for specialized equipment, such as diaphragm type pressure gauges, has surged, leading to a significant rise in the number of exporters in the market. This article delves into the functionalities, advantages, and market dynamics surrounding diaphragm type pressure gauges.

Understanding Diaphragm Type Pressure Gauges

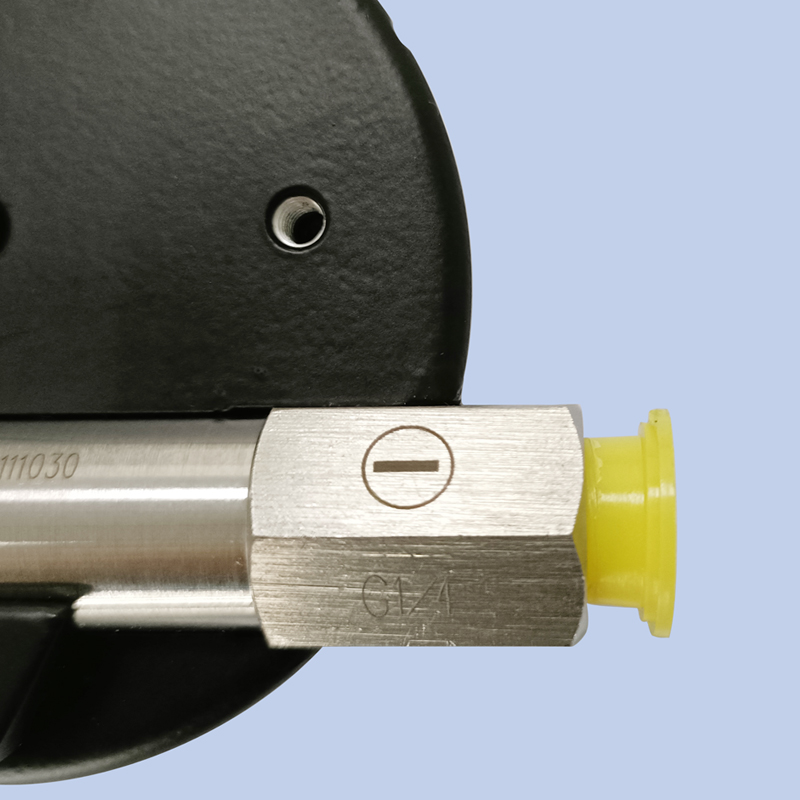

Diaphragm type pressure gauges are a vital component in measuring pressure across a wide range of applications. These gauges utilize a diaphragm, typically made of flexible materials such as stainless steel or polymer, to sense pressure changes. When pressure is applied, it causes the diaphragm to deflect, which is then transmitted to the gauge movement that indicates the pressure level.

This design provides a reliable and accurate means of measuring pressure in both gas and liquid applications. Diaphragm type gauges are known for their versatility and can be used in industries ranging from oil and gas to pharmaceuticals, food and beverage, and chemical processing.

Advantages of Diaphragm Type Pressure Gauges

1. Durability and Resistance to Corrosion One of the standout features of diaphragm type pressure gauges is their robust construction. The use of stainless steel or chemical-resistant materials allows these gauges to withstand harsh environments, making them ideal for corrosive or high-pressure applications.

2. Accuracy and Sensitivity These gauges are designed to deliver precise measurements, even in fluctuating pressure conditions. The sensitive nature of the diaphragm allows for accurate readings, which is critical for maintaining safety and optimizing processes in various industries.

3. Minimal Maintenance Requirements Diaphragm type pressure gauges typically require less maintenance than other types of pressure measurement devices. This is particularly advantageous for companies looking to minimize downtime and operational costs.

4. Wide Range of Applications Their ability to measure both low and high pressures makes diaphragm type gauges suitable for various applications, including steam, oil, water, and gases. This flexibility contributes to their growing presence in numerous sectors.

diaphragm type pressure gauge exporters

Export Trends in Diaphragm Type Pressure Gauges

The growing demand for diaphragm type pressure gauges has paved the way for a flourishing export market. Countries with established manufacturing capabilities, such as Germany, the United States, and China, have become key players in the global supply chain. The increase in international trade agreements and the quest for quality instrumentation at competitive prices have further boosted exports.

Exporters of diaphragm type pressure gauges have diversified their offerings to cater to the specific needs of different industries. Customized gauges that meet unique specifications can be tailored to suit exacting applications, thereby enhancing the relevance of these instruments in varied industrial contexts.

Challenges in the Export Market

While the export market for diaphragm type pressure gauges shows promising growth, it is not without challenges. Intense competition among manufacturers can lead to price wars, potentially jeopardizing quality. Additionally, compliance with international standards and regulations is essential for exporters to gain access to global markets. Ensuring product reliability across different regulatory landscapes can be a significant hurdle.

Moreover, factors such as global supply chain disruptions and fluctuating raw material costs can impact the availability and pricing of diaphragm type pressure gauges. Exporters must navigate these challenges to maintain their competitiveness and ensure customer satisfaction.

The Future of Diaphragm Type Pressure Gauge Exporters

As industries continue to prioritize efficiency and safety, the demand for reliable pressure measurement tools like diaphragm type pressure gauges is expected to rise. Exporters who invest in innovation, quality assurance, and customer relations will likely thrive in this expanding market.

Moreover, the rising focus on environmental sustainability and energy efficiency will drive the need for advanced pressure measuring devices. This presents an excellent opportunity for exporters to develop eco-friendly instruments that meet the evolving standards of modern industries.

In conclusion, diaphragm type pressure gauges play a crucial role in ensuring safety and efficiency across various applications. As the global market for these devices continues to grow, exporters must remain adaptable and proactive to meet the demands of a dynamic industry landscape. With durability, accuracy, and versatile applications, diaphragm type pressure gauges will undoubtedly remain a cornerstone in industrial pressure measurement for years to come.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025