1 月 . 20, 2025 13:53 Back to list

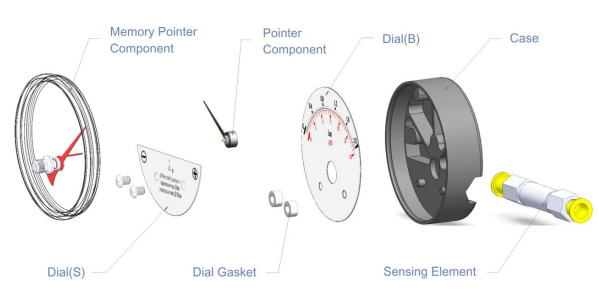

Differential Pressure Gauge-Magnetic piston francois typeYCC-80.03(851.3)

Differential pressure gauges play a crucial role in numerous industries, serving as essential components in measuring and monitoring the pressure difference between two points in a system. Their applications range from filtering systems and flow measurement to HVAC systems and hydraulic applications. In the realm of industrial instrumentation, understanding the complexities and functionalities of differential pressure gauges is imperative for ensuring efficiency, safety, and performance.

Trustworthiness remains a cornerstone in building long-lasting relationships between manufacturers and consumers of differential pressure gauges. Reliable customer support, comprehensive warranties, and responsive service teams create a foundation of trust essential for long-term collaboration. When selecting a provider, industry professionals typically prioritize those who offer detailed product documentation, fully transparent transaction processes, and an impressive track record of client satisfaction. Peer reviews, case studies, and third-party evaluations further aid in identifying reputable brands committed to delivering outstanding performance and client-focused solutions. For businesses seeking to optimize their operations, leveraging the capabilities of differential pressure gauges can lead to substantial improvements in both cost-effectiveness and safety. By actively monitoring pressure differences, these gauges serve as the eyes and ears of a system, providing early warning signals that can prevent equipment failure or downtime. Integrating them into predictive maintenance regimes aligns with modern industrial strategies aimed at maximizing uptime and reducing the total cost of ownership. In conclusion, differential pressure gauges are indispensable tools for accurately measuring pressure variations in diverse industrial applications. With a strong foundation in practical application experience, technical expertise, authoritative manufacturing standards, and trustworthy service, these instruments continue to prove their value. When chosen and implemented correctly, they offer insights that empower businesses to enhance operational efficiency, maintain system integrity, and ultimately drive success in a competitive industrial landscape.

Trustworthiness remains a cornerstone in building long-lasting relationships between manufacturers and consumers of differential pressure gauges. Reliable customer support, comprehensive warranties, and responsive service teams create a foundation of trust essential for long-term collaboration. When selecting a provider, industry professionals typically prioritize those who offer detailed product documentation, fully transparent transaction processes, and an impressive track record of client satisfaction. Peer reviews, case studies, and third-party evaluations further aid in identifying reputable brands committed to delivering outstanding performance and client-focused solutions. For businesses seeking to optimize their operations, leveraging the capabilities of differential pressure gauges can lead to substantial improvements in both cost-effectiveness and safety. By actively monitoring pressure differences, these gauges serve as the eyes and ears of a system, providing early warning signals that can prevent equipment failure or downtime. Integrating them into predictive maintenance regimes aligns with modern industrial strategies aimed at maximizing uptime and reducing the total cost of ownership. In conclusion, differential pressure gauges are indispensable tools for accurately measuring pressure variations in diverse industrial applications. With a strong foundation in practical application experience, technical expertise, authoritative manufacturing standards, and trustworthy service, these instruments continue to prove their value. When chosen and implemented correctly, they offer insights that empower businesses to enhance operational efficiency, maintain system integrity, and ultimately drive success in a competitive industrial landscape.

Share

Latest news

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025