7 月 . 26, 2024 03:25 Back to list

Exploring the Functionality and Applications of Jah Double Diaphragm Differential Pressure Gauge

Understanding the JAH Double Diaphragm Differential Pressure Gauge

In today’s industrial landscape, precise measurement of pressure is essential for ensuring the efficiency and safety of systems in various applications, from HVAC to chemical processing. Among the myriad of tools utilized for this purpose, the JAH Double Diaphragm Differential Pressure Gauge stands out due to its robust design and accuracy. This article will explore the operational principles, applications, and advantages of this specialized instrument.

Operational Principles

The JAH Double Diaphragm Differential Pressure Gauge operates based on the principle of differential pressure measurement. This gauge incorporates two flexible diaphragms that respond to pressure variations between two points in a system. When a pressure difference occurs, one diaphragm moves inwards while the other moves outwards. This movement is then translated into a mechanical displacement, which is indicated on the gauge's scale.

The double diaphragm design enhances the gauge’s sensitivity and accuracy, allowing it to detect even minute pressure differences. Furthermore, it provides a level of isolation between the measuring medium and the gauge's internal components, which is crucial when dealing with corrosive or viscous fluids. The result is a reliable, long-lasting instrument suitable for harsh environments.

Applications

The versatility of the JAH Double Diaphragm Differential Pressure Gauge allows it to be employed in a wide range of applications. In the HVAC industry, it is widely used to monitor filter pressure drops, ensuring optimal airflow and system efficiency. Similarly, in the pharmaceutical and food industries, where hygiene is paramount, these gauges help monitor pressure differences in cleanrooms and sterile environments, ensuring compliance with stringent safety standards.

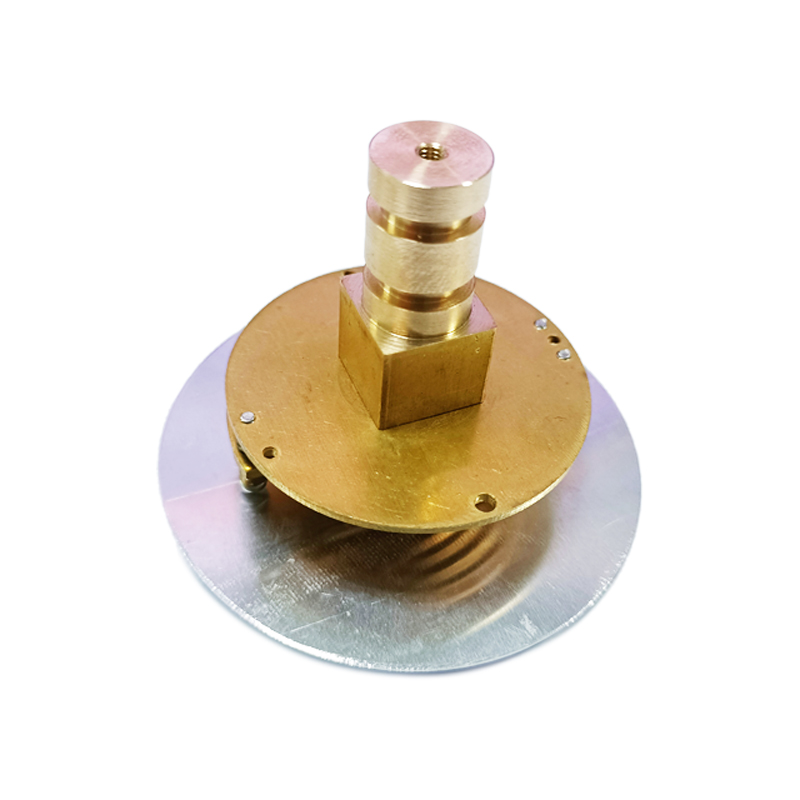

jah double diaphragm differential pressure gauge

In chemical processing, the gauge is used to monitor pressures across reactors and distillation columns, providing critical data for maintaining optimal operating conditions. Additionally, it finds applications in wastewater treatment, where it helps track the pressure changes in filtration systems, enabling operators to make timely interventions when needed.

Advantages

One of the primary advantages of the JAH Double Diaphragm Differential Pressure Gauge is its durability. Designed to withstand fluctuations in pressure and temperature, this gauge is built from high-quality materials that ensure its longevity in tough industrial settings. Moreover, the dual diaphragm configuration minimizes the risk of leakage, a crucial factor in maintaining measurement accuracy and system integrity.

Another significant benefit is its ease of installation and maintenance. With straightforward installation procedures, operators can quickly integrate the gauge into existing systems. Additionally, the gauge requires minimal maintenance, which is a crucial factor in reducing downtime and operational costs.

Furthermore, the gauge provides high accuracy and reliability, essential characteristics in applications where precise pressure measurements are critical to safety and performance. This instrument significantly reduces the risk of operational failures, which can lead to severe financial losses or environmental hazards.

Conclusion

In summary, the JAH Double Diaphragm Differential Pressure Gauge is an essential tool for industries requiring precise pressure measurement. Its robust design, versatility across applications, and reliable performance make it a favored choice among engineers and operators alike. As industries continue to evolve and demand higher standards of safety and efficiency, instruments like the JAH gauge will play an increasingly vital role in meeting these needs. Understanding and utilizing such sophisticated measurement tools will ultimately lead to enhanced productivity and greater operational success.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025