12 月 . 17, 2024 00:20 Back to list

high quality high accuracy differential pressure gauge

High-Quality, High-Accuracy Differential Pressure Gauge Essential for Precision Measurement

In various industrial applications, the need for accurate and reliable measurement tools cannot be overstated. Among these tools, the differential pressure gauge stands out as a crucial instrument for monitoring and controlling processes across numerous sectors, including oil and gas, pharmaceuticals, food and beverage, and HVAC systems. High-quality, high-accuracy differential pressure gauges are indispensable for ensuring optimal performance and safety in these industries.

Understanding Differential Pressure Gauges

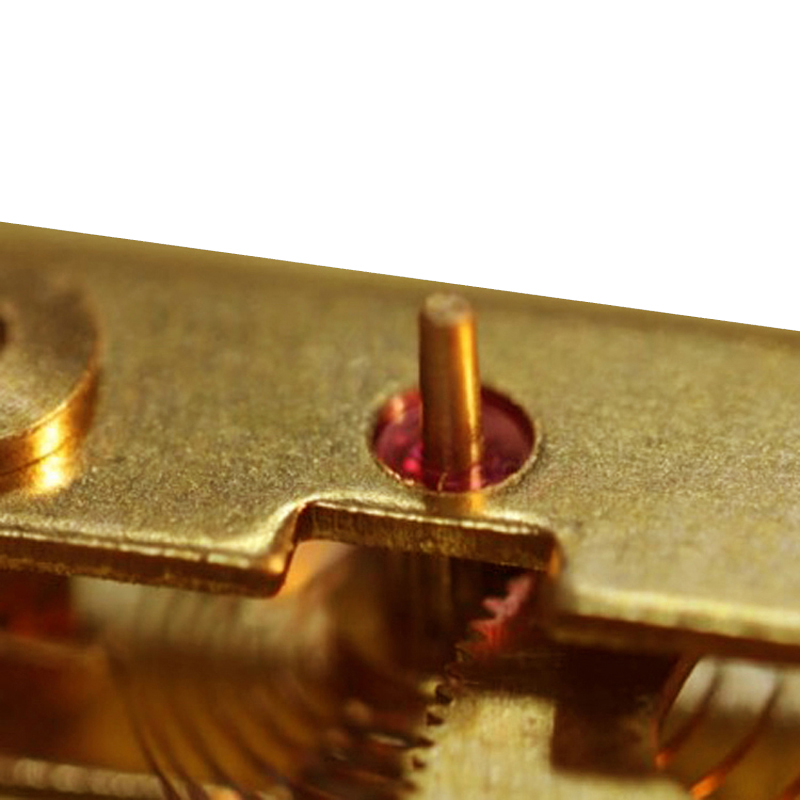

A differential pressure gauge measures the difference in pressure between two points in a system. This measurement is critical for assessing flow rates, detecting blockages, or gauging the performance of filtration systems. These gauges typically consist of two ports for the input of pressure from different locations; the gauge then calculates and displays the difference in pressure.

Importance of High Quality

The quality of a differential pressure gauge directly impacts its performance and longevity. High-quality gauges are designed to withstand harsh conditions, such as extreme temperatures and corrosive environments. They often feature robust materials, like stainless steel or special polymers, that provide durability and resistance to wear and tear. Furthermore, high-quality gauges are manufactured under stringent quality control processes, ensuring their reliability and accuracy over extended periods.

High Accuracy A Non-Negotiable Requirement

In many applications, the accuracy of pressure measurements can significantly affect operational efficiency and safety. A high-accuracy differential pressure gauge minimizes measurement errors, which can lead to costly downtimes or even catastrophic failures. An accurate gauge allows engineers and operators to fine-tune processes, ensuring that systems run at optimal conditions.

high quality high accuracy differential pressure gauge

Different industries have varying definitions of what constitutes high accuracy. Generally, a gauge with an accuracy of ±0.1% full scale is considered high quality. However, for certain critical applications, even tighter tolerances may be required. For example, in cleanroom environments used in pharmaceuticals, gauges with accuracies as tight as ±0.01% can be crucial for ensuring product safety and compliance with regulatory standards.

Advanced Technologies in Differential Pressure Measurement

Recent advancements in technology have further enhanced the capabilities of differential pressure gauges. Many high-quality models now include digital displays and smart features, such as programmable alarms and data logging. These features allow operators to monitor conditions in real-time and make data-driven decisions.

Wireless technology is another significant advancement. Many modern differential pressure gauges can transmit data wirelessly to centralized monitoring systems, facilitating remote access to critical information. This is especially beneficial in situations where conditions are hazardous, allowing for safer and more efficient operations.

Calibration and Maintenance

To maintain accuracy, regular calibration and maintenance of differential pressure gauges are essential. A high-quality gauge should come with a calibration certificate and guidelines for periodic checks. Calibration involves adjusting the gauge to ensure that its readings match known standards. Proper maintenance, including cleaning and replacing worn components, extends the life of the gauge and preserves its accuracy.

Conclusion

In conclusion, high-quality, high-accuracy differential pressure gauges play a vital role in various industrial applications. Their ability to provide precise measurements can enhance operational efficiency, prevent costly downtimes, and ensure safety. When selecting a differential pressure gauge, it is essential to consider not only its accuracy and quality but also the specific requirements of the application to ensure optimal performance. Investing in reliable measurement tools is fundamental for businesses aiming to maintain a competitive edge in today's fast-paced industrial landscape. By understanding and utilizing high-quality differential pressure gauges, industries can achieve greater precision and reliability in their operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025