8 月 . 12, 2024 14:46 Back to list

Innovative Differential Pressure Gauge with Sealed Capillary Design for Enhanced Accuracy and Reliability

Understanding Differential Pressure Gauges with Sealed Capillaries

In industrial settings, monitoring pressure differences is critical for system performance, safety, and efficiency. One of the essential tools used for this purpose is the differential pressure gauge, particularly those equipped with sealed capillaries. These gauges provide accurate readings for processes where maintaining pressure integrity is crucial, such as in chemical processing, water treatment, and HVAC systems.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device designed to measure the difference between two pressure points within a system. By doing so, it helps identify blockages, filter fouling, and equipment performance. The gauge typically consists of two pressure ports connected to a sensing element that translates pressure differences into a readable output, often displayed as a needle on a dial or a digital readout.

The Role of Sealed Capillaries

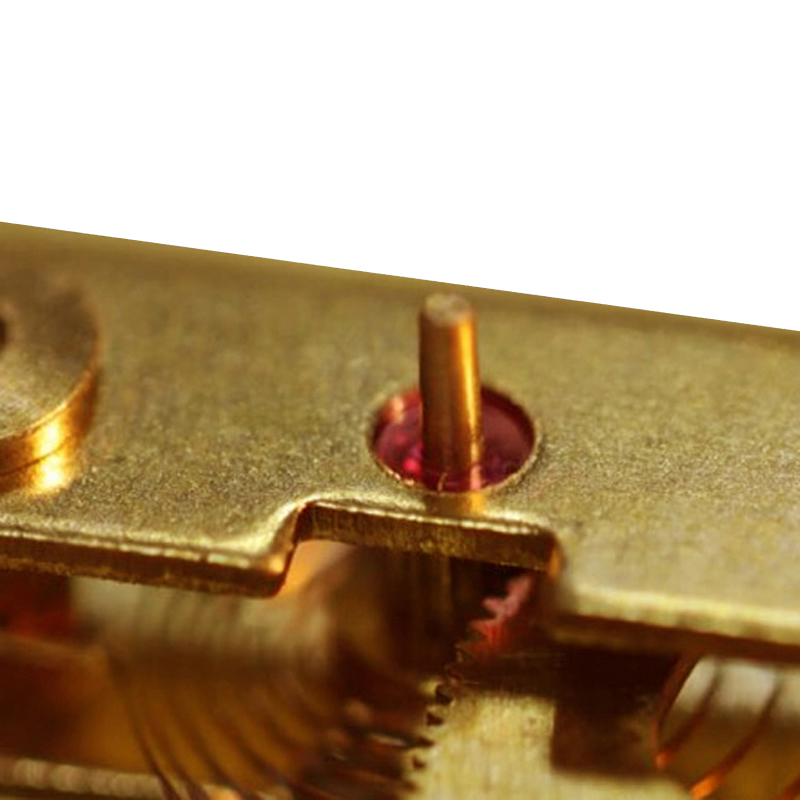

Sealed capillaries play an essential role in the functionality of differential pressure gauges. They are typically made from materials resistant to various chemicals and environmental factors to ensure durability and reliability. These capillaries transmit pressure signals from the measurement points to the sensing element of the gauge, while also preventing contamination from external substances, thus ensuring the purity of the measured medium.

Using sealed capillaries is particularly advantageous in applications where external pressure variations or contaminants could interfere with accurate readings. For example, in environments with high humidity or extreme temperatures, traditional open tubes could lead to erroneous measurements due to the absorption of moisture or thermal expansion.

Advantages of Differential Pressure Gauges with Sealed Capillaries

differential pressure gauge with sealed capilary products

1. Accuracy and Reliability The sealed capillary design minimizes the risk of external interference in the measurement process, leading to more precise readings. This accuracy is vital for critical applications where even slight variations in pressure can lead to significant operational issues.

2. Protection Against Contamination By sealing the measurement system, these gauges protect the sensing elements from dirt, dust, and other contaminants that could compromise their performance. This is particularly important in industries such as pharmaceuticals and food processing, where cleanliness is paramount.

3. Versatility Differential pressure gauges with sealed capillaries can be used in a wide range of applications, from monitoring filter conditions in water treatment plants to measuring the pressure drop in HVAC systems. Their adaptability makes them a preferred choice for many engineers and technicians.

4. Durability These gauges are often designed to withstand harsh operating conditions, including extreme temperatures and corrosive environments. The robust construction ensures a long service life, reducing maintenance costs and downtime.

5. Ease of Installation Many differential pressure gauges with sealed capillaries are designed for easy installation and integration into existing systems. They often come with comprehensive manuals and support from manufacturers, making them user-friendly even for those with limited experience in pressure measurement.

Conclusion

Differential pressure gauges equipped with sealed capillaries are invaluable tools in the industrial landscape. Their ability to provide accurate measurements while resisting contamination makes them ideal for a variety of applications. As industries continue to prioritize operational efficiency and safety, the demand for reliable pressure monitoring solutions like these will only grow. Understanding their advantages can help engineers and technicians make informed choices in selecting the right instruments for their specific needs, ensuring optimal performance of their systems.

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025

-

Wika Diaphragm Seal Pressure Gauge High-Accuracy & Durable Solutions

NewsMay.18,2025

-

Diaphragm Type Differential Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.17,2025