12 月 . 20, 2024 05:06 Back to list

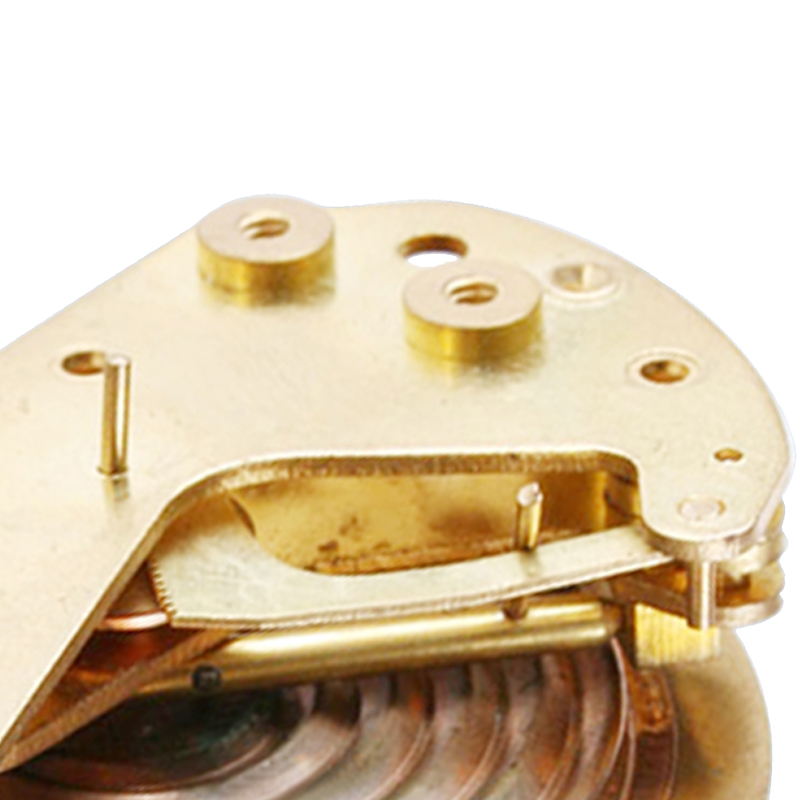

mass diaphragm pressure gauge

Understanding Mass Percentage Diaphragm Pressure Gauges

In the field of engineering and process control, pressure measurement is crucial for the safe and efficient operation of various systems. One specific type of pressure gauge that has gained popularity is the mass percentage diaphragm pressure gauge. This device combines the principles of diaphragm pressure sensing with the measurement of mass percentage, presenting advantages in certain applications.

The Basics of Diaphragm Pressure Gauges

A diaphragm pressure gauge is a device that utilizes a thin, flexible membrane (the diaphragm) to measure pressure. When pressure is applied, the diaphragm flexes, and this deflection is translated into a measurement that can be read on a scale or digital display. Diaphragm gauges are particularly useful for measuring low to medium pressures and are resistant to corrosive media, making them suitable for various industrial applications.

Concept of Mass Percentage Measurement

Mass percentage is a way of expressing the concentration of a component in a mixture. It is calculated as the mass of the specific component divided by the total mass of the mixture, multiplied by 100%. For instance, in a solution of saltwater, if you have 5 grams of salt in 100 grams of the solution, the mass percentage of salt would be 5%. In industrial settings, it’s vital to monitor mass percentages to ensure product quality and process efficiency.

Integrating Mass Percentage into Diaphragm Gauges

Mass percentage diaphragm pressure gauges have been developed to provide both pressure readings and mass percentage indications. This integration allows operators to simultaneously monitor pressure levels and the concentration of specific components within a system or a reaction mixture. The design typically incorporates a sensing diaphragm that responds to pressure changes, alongside sensors that analyze the composition of the fluid or gas in the system.

This combination is particularly beneficial in chemical processing, pharmaceuticals, and food production, where maintaining specific concentrations is crucial. For instance, in a fermentation process, controlling the concentration of yeast and sugars can significantly affect the quality and yield of the final product. A mass percentage diaphragm pressure gauge can help maintain optimal conditions by providing real-time data that enables swift adjustments to the process.

mass diaphragm pressure gauge

Advantages of Mass Percentage Diaphragm Pressure Gauges

1. Real-Time Monitoring One of the primary advantages is the ability to monitor both pressure and mass percentage simultaneously, allowing for immediate adjustments and higher precision in processes where concentration affects reaction rates.

2. Space Efficiency By integrating two functions into a single device, these gauges save space and reduce installation complexity compared to using separate devices for pressure and mass percentage measurements.

3. Enhanced Safety Real-time monitoring of mass percentage can identify when a mixture approaches unsafe concentrations, providing critical data that can prevent hazardous situations.

4. Versatility These gauges can be used in various industries, including chemical manufacturing, oil and gas, food and beverage, and water treatment, making them highly versatile tools for engineers and operators.

Challenges and Considerations

While mass percentage diaphragm pressure gauges offer significant benefits, there are also challenges. The accuracy of the readings can depend on factors such as temperature fluctuations, changes in fluid density, and the chemical properties of the materials being measured. As such, it is essential to calibrate these devices regularly and select appropriate materials that can withstand the operational environment.

In conclusion, mass percentage diaphragm pressure gauges represent an important advancement in pressure measurement technology. By integrating the measurement of mass percentage with traditional pressure sensing, they provide valuable insights that can enhance process control, improve safety, and optimize product quality. As industries continue to evolve, such innovative solutions will play a key role in meeting the demands for precision and efficiency in operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025