2 月 . 05, 2025 00:55 Back to list

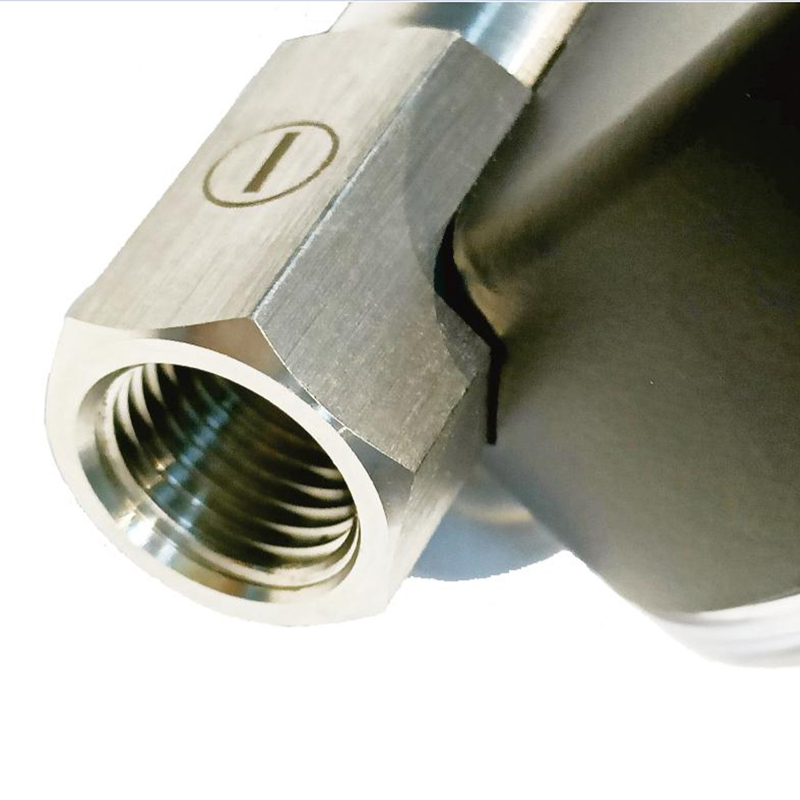

oem piston type differential pressure gauge

In the intricate world of precision measurement technology, the OEM piston type differential pressure gauge emerges as a critical device used across various industries, including the oil and gas sector, the chemical processing industries, and HVAC systems. This type of pressure gauge is paramount for facilities where reliable and accurate pressure monitoring is indispensable. Understanding its unparalleled design, operational mechanics, and extensive applications underscores its reputation as a tool of choice for experts worldwide.

For industry professionals, selecting an OEM piston type differential pressure gauge goes beyond purchasing an instrument. It's about building trust with a component known for its authoritative performance. With a proven track record, these gauges provide transparency and accountability in operations, reducing uncertainties that could potentially compromise efficiency and safety. Their utility in the oil and gas industry, for instance, underscores their pivotal role. Oil extraction and processing require precise pressure monitoring to ensure the integrity of pipelines and process safety. The chemical processing field is no different—where dangerous substances are handled, the accuracy of pressure measurements provided by piston-type gauges fosters safety and optimizes process performance. In HVAC systems, these gauges contribute significantly to maintaining operational balance and energy efficiency. By accurately assessing pressure differences across components such as filters and fans, they ensure that systems run smoothly, reduce energy consumption, and extend equipment lifespan. This capability translates directly to cost savings, a factor every expert eyeing operational efficiency will value. Amidst their broad applications, the trustworthiness of OEM piston type differential pressure gauges cannot be overstated. Clarity and reliability in measurement are indispensable, especially when system integrity and personnel safety are on the line. Their sophisticated yet user-friendly design ensures that operators across various expertise levels can effectively employ these gauges, interpreting the data accurately and making informed choices. In conclusion, OEM piston type differential pressure gauges signify more than just measurement instruments; they represent an industry benchmark in engineering effectiveness and trust—a blend of unrivaled expertise and authority that professionals across the globe continuously rely upon. They are a testament to what happens when engineering excellence meets real-world applications, providing solutions that safeguard processes, ensure quality outcomes, and confer peace of mind in operational endeavors.

For industry professionals, selecting an OEM piston type differential pressure gauge goes beyond purchasing an instrument. It's about building trust with a component known for its authoritative performance. With a proven track record, these gauges provide transparency and accountability in operations, reducing uncertainties that could potentially compromise efficiency and safety. Their utility in the oil and gas industry, for instance, underscores their pivotal role. Oil extraction and processing require precise pressure monitoring to ensure the integrity of pipelines and process safety. The chemical processing field is no different—where dangerous substances are handled, the accuracy of pressure measurements provided by piston-type gauges fosters safety and optimizes process performance. In HVAC systems, these gauges contribute significantly to maintaining operational balance and energy efficiency. By accurately assessing pressure differences across components such as filters and fans, they ensure that systems run smoothly, reduce energy consumption, and extend equipment lifespan. This capability translates directly to cost savings, a factor every expert eyeing operational efficiency will value. Amidst their broad applications, the trustworthiness of OEM piston type differential pressure gauges cannot be overstated. Clarity and reliability in measurement are indispensable, especially when system integrity and personnel safety are on the line. Their sophisticated yet user-friendly design ensures that operators across various expertise levels can effectively employ these gauges, interpreting the data accurately and making informed choices. In conclusion, OEM piston type differential pressure gauges signify more than just measurement instruments; they represent an industry benchmark in engineering effectiveness and trust—a blend of unrivaled expertise and authority that professionals across the globe continuously rely upon. They are a testament to what happens when engineering excellence meets real-world applications, providing solutions that safeguard processes, ensure quality outcomes, and confer peace of mind in operational endeavors.

Share

Latest news

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025