12 月 . 04, 2024 19:09 Back to list

Manufacturers of Piston Type Differential Pressure Gauges for Industrial Applications

Understanding Piston Type Differential Pressure Gauges A Comprehensive Overview

Differential pressure gauges are critical instruments employed across various industries to measure the difference in pressure between two points within a system. Among the different types of differential pressure gauges available, the piston type is noteworthy due to its unique design and operational advantages. This article explores the mechanisms, manufacturers, applications, and benefits of piston type differential pressure gauges.

Mechanism of Operation

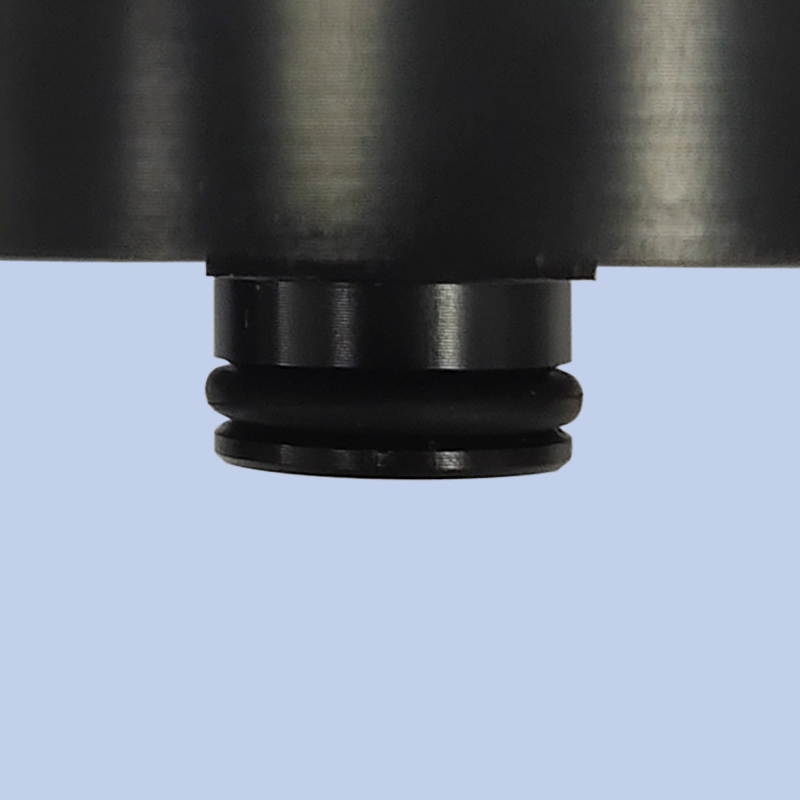

The piston type differential pressure gauge operates on the principle of balancing forces. It consists of a piston housed within a cylinder that moves in response to differences in pressure on either side. When there is a pressure differential, the piston is displaced, and this movement is translated into a readable measurement on the gauge. The design allows for increased sensitivity and accuracy, making it preferable in situations where precise measurements are critical.

The gauge typically incorporates a spring to bring the piston back to its original position once the differential pressure is removed. Additionally, many models feature limit stops to prevent over-travel and component damage, ensuring reliability in demanding conditions.

Key Manufacturers

The market for piston type differential pressure gauges is competitive, with several renowned manufacturers leading the industry. Companies like Ashcroft, WIKA, and Yokogawa have established themselves as reliable providers, offering a variety of models tailored for specific applications. Ashcroft is particularly known for its durable and high-performance gauges that can withstand harsh environmental conditions, while WIKA specializes in hygienic designs ideal for food and pharmaceutical industries.

Other notable manufacturers include Omega Engineering and Parker Hannifin. Omega’s gauges often feature digital outputs, enhancing data logging and integration into automated systems. Parker, on the other hand, focuses on rugged designs suitable for industrial applications that require a high degree of robustness.

Applications

piston type differential pressure gauge manufacturers

Piston type differential pressure gauges find applications in numerous fields, including HVAC systems, water treatment plants, medical devices, and chemical processing. In HVAC systems, they are instrumental in monitoring air pressure differentials across filters and ducts, allowing for efficient operation and maintenance of air quality.

In the water treatment industry, these gauges help in monitoring pressure drops across membrane systems and filters, ensuring that the filtration process remains effective. Medical devices, particularly those used in respiratory care, utilize piston type gauges for accurate pressure monitoring of gases. The chemical processing industry also relies on these gauges for maintaining pressure differential in reactors and separation processes.

Advantages of Piston Type Differential Pressure Gauges

The piston type differential pressure gauge offers several key benefits over other measuring devices. Firstly, the mechanical design inherently provides high accuracy and repeatability, essential for critical applications. The capability to handle both high and low-pressure systems makes it versatile, suitable for many different installations.

Moreover, these gauges are relatively easy to install and maintain. Their robust design means they can endure harsh conditions without significant wear and tear, which can be a common concern with electronic gauges. Additionally, the absence of complex electronic components reduces the vulnerability to electrical failures, making piston type gauges a dependable choice in industrial environments.

Conclusion

Piston type differential pressure gauges are indispensable tools in various industries, providing accurate and reliable pressure measurements essential for smooth operations. With several reputable manufacturers producing high-quality gauges, users can find models designed for specific needs, ensuring that the demands of different applications are met efficiently.

The combination of mechanical simplicity and high performance makes piston type differential pressure gauges a favored choice for professionals seeking precision in their measurements. As technology advances, the evolution of these gauges will likely continue, further enhancing their capabilities and expanding their range of applications in the future.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025