12 月 . 27, 2024 14:45 Back to list

precise pressure gauge pricelist

Understanding the Pricing of Precision Pressure Gauges

Precision pressure gauges are essential tools in various industries, including manufacturing, automotive, pharmaceuticals, and many others. The accurate measurement of pressure is critical for ensuring the safety and efficiency of processes, making the selection of the right pressure gauge vital. In this article, we will explore the factors that influence the price of precision pressure gauges and provide insights into how to navigate the pricing landscape effectively.

What Are Precision Pressure Gauges?

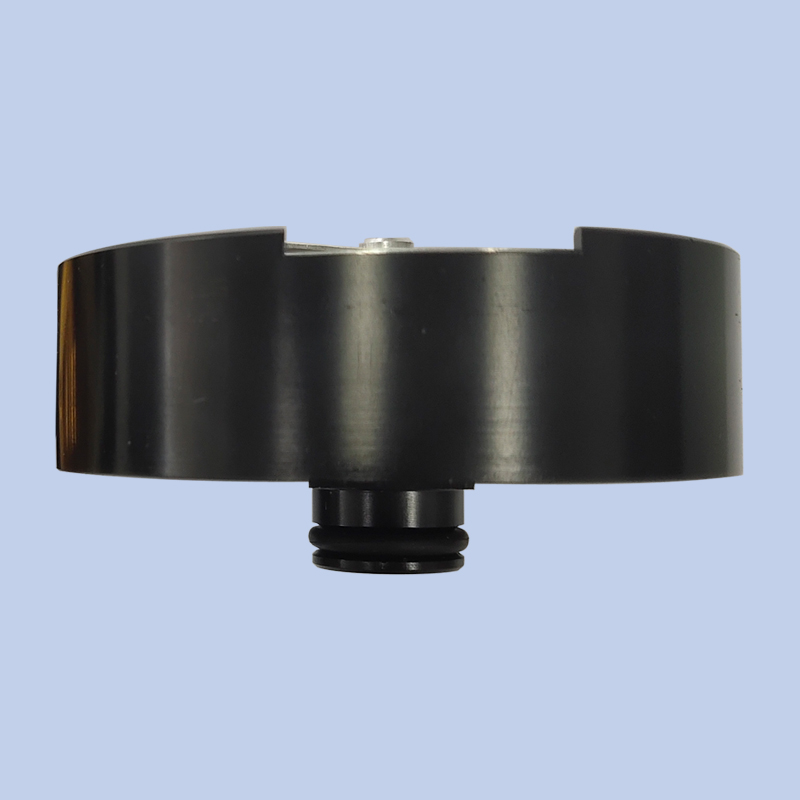

Precision pressure gauges are instruments designed to measure the pressure of gases or liquids with high accuracy. Unlike standard gauges, which may provide a rough approximation, precision gauges are calibrated to deliver exact readings, often to within 1% of the actual pressure. They can be analog or digital and typically come equipped with features such as temperature compensation, various measurement ranges, and connections to various pressure systems.

Factors Influencing Price

1. Type of Gauge The type of pressure gauge significantly influences its cost. For instance, digital gauges tend to be more expensive than their mechanical counterparts due to advanced technology features. While mechanical gauges may serve basic needs, digital gauges offer enhanced precision and user-friendly interfaces.

2. Accuracy and Calibration The accuracy level required for specific applications can drive up the price. Gauges that offer higher accuracy (e.g., ±0.1% full scale) are typically more expensive, as they require more sophisticated manufacturing processes and materials. Additionally, gauges that come pre-calibrated or are traceable to national standards also tend to be pricier.

3. Material and Construction The materials used in manufacturing the gauge play a significant role in pricing. High-quality stainless steel, for instance, offers better durability and resistance to environmental factors compared to plastic alternatives. Gauges designed for harsh conditions or high-pressure environments will usually command higher prices due to the materials and technology involved in their construction.

precise pressure gauge pricelist

4. Brand Reputation Established brands with a proven track record of reliability and accuracy often charge a premium for their products. Investing in a gauge from a reputable manufacturer can be wise, particularly for critical applications where precision is paramount.

5. Special Features Additional features can also impact the pricing of precision pressure gauges. Options such as built-in data logging, remote monitoring capabilities, and enhanced display controls can increase the cost. When choosing a gauge, it's essential to evaluate which features will add value to your specific application.

6. Volume of Purchase Pricing can also vary based on the volume of gauges purchased. Many suppliers offer discounts for bulk purchases, making it cost-effective for companies that require multiple units.

Evaluating Price Lists

When reviewing a precision pressure gauge price list, it's essential to consider not just the upfront cost but also the long-term value. A cheaper gauge may save money initially but could lead to increased costs due to inaccuracies or the need for more frequent replacements. Likewise, high-quality gauges may have a higher upfront cost but can save money in the long run by improving operational efficiency and reducing downtime.

Conclusion

Navigating the price landscape of precision pressure gauges requires careful consideration of various factors, including type, accuracy, materials, brand reputation, features, and purchase volume. By understanding these elements, buyers can make informed decisions that align with their operational needs and budget. Precision in pressure measurement is crucial, and investing in the right gauge is an investment in the efficiency and safety of your operations. Whether you are a small business or a large corporation, selecting the appropriate pressure gauge will ultimately contribute to improved productivity and reliability in your processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025