8 月 . 15, 2024 02:12 Back to list

Understanding the Functionality and Applications of ODM Diaphragm Pressure Gauges in Modern Industry

Understanding ODM Diaphragm Pressure Gauges

In the realm of industrial applications, precision and reliability are paramount, especially when monitoring and controlling pressure in various systems. One of the key instruments that serve this purpose is the diaphragm pressure gauge. Among the various types available, the ODM diaphragm pressure gauge stands out for its design, accuracy, and versatility. This article delves into the construction, working principles, applications, and advantages of the ODM diaphragm pressure gauge.

Construction and Working Principle

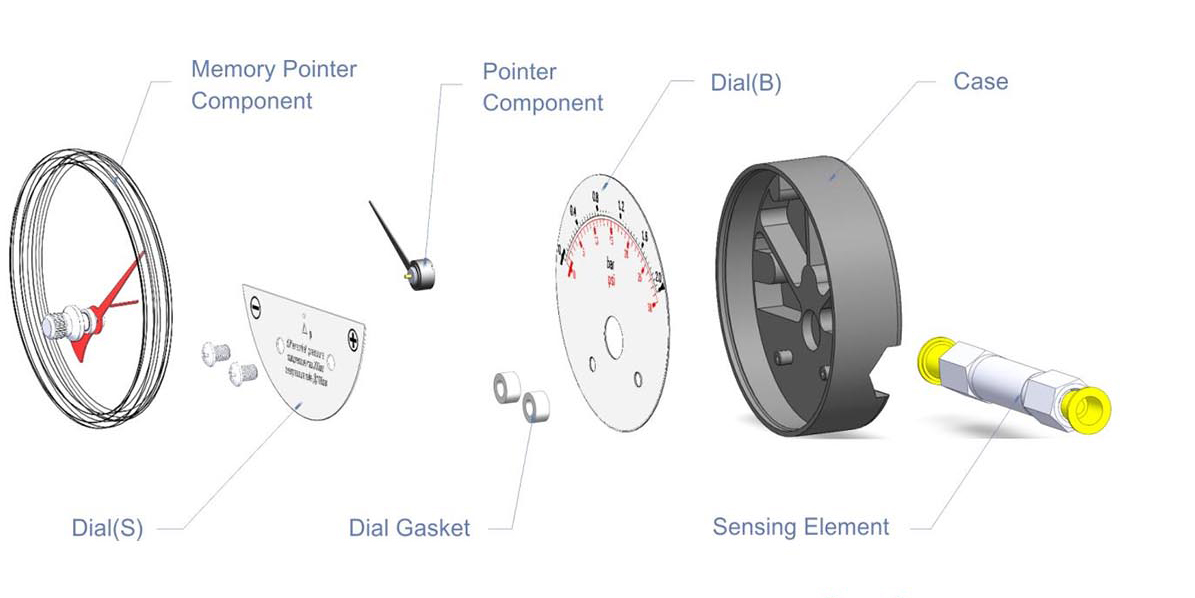

The ODM diaphragm pressure gauge consists of a sealed casing, a diaphragm, and an internal mechanism to display the pressure reading. The diaphragm is a flexible membrane usually made from materials like stainless steel or other corrosion-resistant alloys. When pressure is applied to one side of the diaphragm, it flexes in response to the force exerted by the fluid or gas in the system.

This flexing movement is then translated into a rotational movement by the mechanical linkage connected to a pointer on the dial. The pressure reading is displayed in various units, such as psi, bar, or kPa, making it suitable for different applications. The design ensures that the gauge can handle a variety of fluids, including corrosive or viscous substances.

Applications

ODM diaphragm pressure gauges are utilized across various industries, including oil and gas, chemical processing, water treatment, and manufacturing. They play a crucial role in monitoring pressure in systems such as boilers, compressors, tanks, and pipelines. The ability to measure low and high pressures makes them an ideal choice for diverse applications.

In the food and beverage industry, for instance, ODM diaphragm gauges are used to ensure that the pressure levels remain within safe limits during production processes. Their hygienic design is crucial for maintaining product quality and safety. Similarly, in HVAC systems, these gauges help monitor pressure variations to ensure optimal performance and efficiency.

odm diaphragm pressure guage

Advantages

The ODM diaphragm pressure gauge offers several advantages that make it a preferred choice for many applications. Firstly, its robust construction allows it to withstand harsh environments, including extreme temperatures and corrosive conditions. This durability translates into a longer operational lifespan and reduced maintenance costs.

Secondly, the sensitivity of the diaphragm mechanism provides high accuracy in pressure readings. This precision is vital in applications where minor pressure changes can have significant consequences on operations and safety. The wide range of measurement capabilities—from absolute to gauge pressure—further enhances its versatility.

Moreover, the design of ODM diaphragm gauges minimizes the risk of fluid contamination. Since the diaphragm isolates the measuring element from the pressure medium, it prevents any aggressive fluids from damaging the internal mechanisms, ensuring reliable performance over time.

Lastly, these gauges can be customized with additional features such as electrical contacts, alarms, and digital displays. Such adaptations provide greater functionality and integration into automated systems, facilitating better monitoring and control.

Conclusion

In conclusion, the ODM diaphragm pressure gauge represents a vital component in the toolkit of pressure monitoring solutions. Its precise construction, reliable performance, and broad applicability make it indispensable in various industrial processes. As industries continue to evolve and demand higher standards of accuracy and durability, the importance of instruments like the ODM diaphragm pressure gauge will only grow, paving the way for advancements in safety and efficiency. Whether monitoring pressure in a manufacturing plant or ensuring the functionality of HVAC systems, these gauges are essential for optimizing performance and maintaining system integrity.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025