ديسمبر . 21, 2024 02:00 Back to list

custom sanitary differential pressure gauge

Understanding Custom Sanitary Differential Pressure Gauges

In industries where hygiene and cleanliness are paramount, such as food processing, pharmaceuticals, and biotechnology, the tools and instruments used must adhere to the strictest sanitary standards. One such instrument that plays a crucial role in these sectors is the sanitary differential pressure gauge. This article will delve into the importance, design, applications, and considerations of custom sanitary differential pressure gauges.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device that measures the difference in pressure between two points in a system. This measurement is vital in many processes, as it can indicate flow rates, filter conditions, and system health. In sanitary applications, these gauges must be designed to prevent contamination and ensure that no substances can adhere to their surfaces or enter the system.

The Importance of Customization

While standard differential pressure gauges may suffice for less stringent applications, custom gauges are often necessary for industries that require tailored solutions. Customization allows manufacturers to meet specific requirements such as size, material, measurement range, and connection types.

For instance, in the food and beverage industry, it’s crucial to use materials that comply with FDA regulations. Manufacturers often opt for stainless steel or other non-corrosive, easy-to-clean materials that can withstand rigorous sanitation processes. Moreover, custom gauges can feature smooth surfaces and specialized designs to minimize the risk of bacteria growth.

Design Features

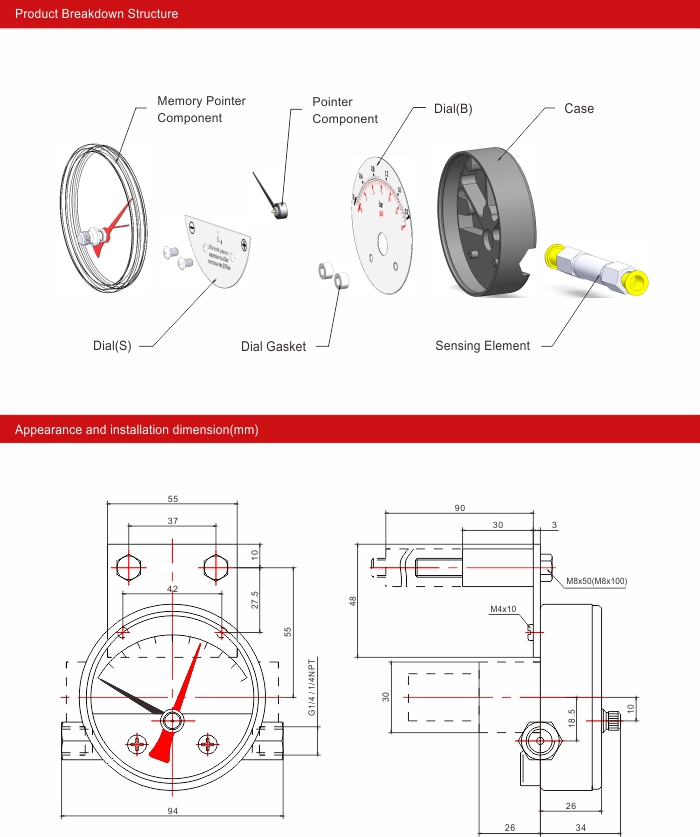

Custom sanitary differential pressure gauges are typically designed with several key features to ensure hygiene and functionality

1. Sanitary Connections These gauges often incorporate tri-clamp fittings or other sanitary connections that allow for easy installation and removal while preventing leakage and contamination.

custom sanitary differential pressure gauge

2. Sealed Construction A sealed design prevents the ingress of contaminants while preserving the integrity of the measured fluids. This is especially important in applications where maintaining a sterile environment is crucial.

3. Easy Cleaning The gauge’s design often facilitates cleaning procedures, whether through steam sterilization, chemical cleaning, or other methods. Smooth surfaces and minimal crevices help eliminate potential contamination points.

4. Material Selection As mentioned earlier, the choice of materials is significant. The use of high-grade stainless steel, for example, ensures durability and resistance to corrosion while maintaining the necessary hygiene standards.

5. Calibration and Accuracy Custom gauges can be calibrated to meet specific pressure ranges and required accuracy levels for different processes, ensuring optimal performance in critical applications.

Applications in Various Industries

Custom sanitary differential pressure gauges find application in numerous fields. In the pharmaceutical industry, they are utilized to monitor filtration processes, ensuring that products remain uncontaminated and safe. Conversely, in wastewater treatment plants, these gauges help in tracking pressure drops across filters, which is vital for maintaining system efficiency.

In the food and beverage sector, they can monitor pressure differences in pasteurization systems or hoppers during product transfer, ensuring that processes stay within safe operational parameters.

Conclusion

In summary, custom sanitary differential pressure gauges are indispensable tools in industries that prioritize hygiene and safety. Their tailored design, which includes sanitized materials, easy-to-clean features, and precise calibration, makes them ideally suited for the unique challenges of food processing, pharmaceuticals, and biotechnology. By investing in custom solutions, businesses can enhance their process efficiency while ensuring the safety and quality of their products. As industries continue to evolve, the demand for such specialized instruments will undoubtedly grow, reinforcing their importance in modern manufacturing and processing environments.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025