Introducing the Railway Pressure Gauge: Precision Meets Durability

In the world of railway operations, precision and reliability are paramount. The Railway Pressure Gauge is engineered to meet the rigorous demands of the railway industry, ensuring that every measurement is accurate and every operation runs smoothly. Whether you are monitoring steam pressure in locomotives or hydraulic pressure in braking systems, our Railway Pressure Gauge is the ideal solution for your needs.

Unmatched Accuracy and Reliability

At the heart of the Railway Pressure Gauge is a commitment to accuracy. Designed with advanced technology, this gauge provides precise readings that you can trust. With a measurement range tailored specifically for railway applications, it ensures that you can monitor pressure levels with confidence. The gauge features a clear, easy-to-read dial that allows for quick assessments, minimizing downtime and enhancing operational efficiency.

Robust Construction for Harsh Environments

Railway operations often take place in challenging environments, where equipment is subjected to extreme temperatures, vibrations, and potential impacts. The Railway Pressure Gauge is built to withstand these conditions. Constructed from high-quality materials, it boasts a rugged casing that protects the internal mechanisms from damage. The gauge is also resistant to corrosion, ensuring longevity and reliability even in the most demanding settings.

User-Friendly Design

We understand that ease of use is crucial for railway personnel. The Railway Pressure Gauge is designed with the user in mind. Its intuitive layout and straightforward installation process mean that you can integrate it into your existing systems with minimal effort. The gauge is equipped with a standard mounting option, allowing for versatile placement in various locations, whether on a locomotive or within a maintenance facility.

Versatile Applications

The Railway Pressure Gauge is not just limited to one application; it is versatile enough to be used across a range of railway systems. From monitoring the pressure of air brakes to assessing hydraulic systems, this gauge is an essential tool for ensuring safety and efficiency. Its adaptability makes it a valuable addition to any railway maintenance toolkit, providing peace of mind that your systems are operating within safe parameters.

Commitment to Safety

Safety is a top priority in the railway industry, and the Railway Pressure Gauge plays a crucial role in maintaining safe operations. By providing accurate pressure readings, it helps prevent potential failures that could lead to accidents or costly repairs. Regular monitoring with our gauge ensures that all systems are functioning optimally, contributing to the overall safety of railway operations.

Customer Support and Warranty

We stand behind the quality of our Railway Pressure Gauge with a comprehensive warranty and dedicated customer support. Our team of experts is available to assist you with any questions or concerns, ensuring that you get the most out of your investment. We believe in building long-term relationships with our customers, and our commitment to service is a testament to that philosophy.

In conclusion, the Railway Pressure Gauge is an indispensable tool for anyone involved in railway operations. With its combination of precision, durability, and user-friendly design, it is the perfect solution for monitoring pressure in various railway applications. Invest in the Railway Pressure Gauge today and experience the difference that accuracy and reliability can make in your operations. Ensure safety, enhance efficiency, and keep your railway systems running smoothly with this essential instrument.

-

railway pressure gauge-double-pointers-double-tubesYTS-100Z

-

railway pressure gauge - Single pointer, single tube typeY-60Z

-

railway pressure gauge - Single pointer, single tube typeY60-2

-

railway pressure gauge-single pointer-single tube typeY60-1

-

railway pressure gauge- single pointer-single tube typeY-60T

-

railway pressure gauge-single pointer-tube typeY-100

-

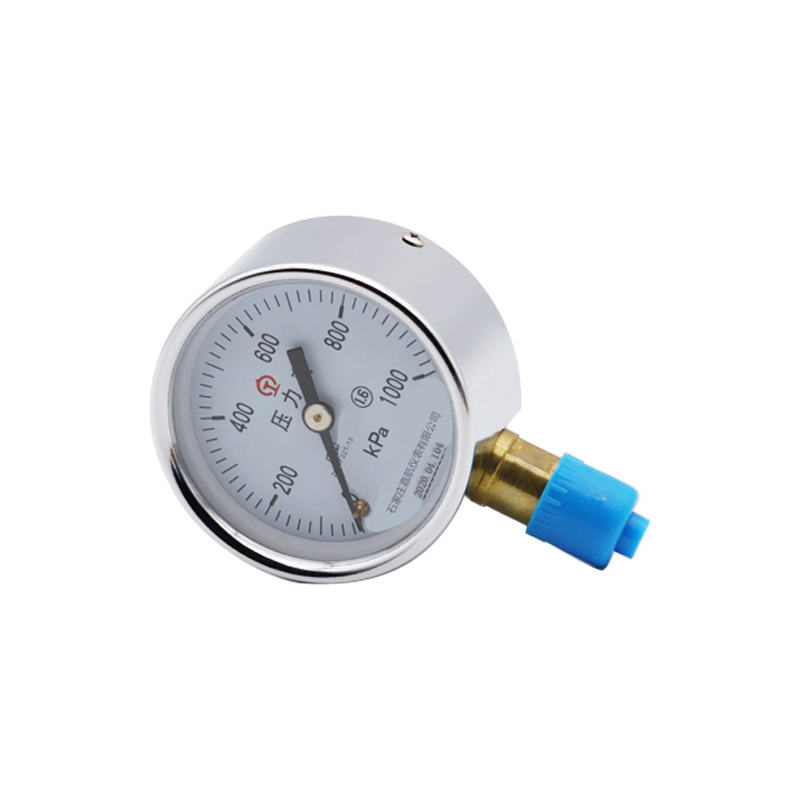

water pressure gauge-railway pressure gauge -YH-100

-

railway pressure gauge-single pointer-tube typeY-100T

-

railway pressure gauge-double pointers-double tubes typeYZS-102

What Is A Railway Pressure Gauge?

A railway pressure gauge is a device used to measure the pressure of fluids within a system, typically in the context of steam, air, or hydraulic systems in trains. These gauges are designed to withstand the harsh conditions of railway environments, including vibrations, temperature fluctuations, and exposure to various elements. They provide real-time data that is crucial for the safe operation of trains.

The Function of Railway Pressure Gauges: Ensuring Safety and Efficiency in Rail Transport

In the realm of railway transport, safety and efficiency are paramount. One of the critical components that contribute to these aspects is the railway pressure gauge. This instrument plays a vital role in monitoring and regulating the pressure within various systems of a train, ensuring that everything operates smoothly and safely. Understanding the function of railway pressure gauges is essential for anyone involved in the rail industry, from engineers to operators.

Key Functions of Railway Pressure Gauges

1. Monitoring System Pressure: The primary function of a railway pressure gauge is to monitor the pressure levels within different systems of the train. This includes the braking system, fuel systems, and pneumatic systems. By providing accurate readings, these gauges help ensure that the pressure remains within safe operating limits.

2. Safety Assurance: Safety is a top priority in railway operations. Pressure gauges serve as an early warning system for potential issues. For instance, if the pressure in the braking system drops below a certain threshold, it could indicate a leak or malfunction. Operators can take immediate action to address the problem before it escalates into a more serious safety hazard.

3. Performance Optimization: Efficient operation of a train is not just about safety; it’s also about performance. Railway pressure gauges help in optimizing the performance of various systems. For example, in pneumatic systems, maintaining the correct air pressure is crucial for the effective functioning of doors, brakes, and other components. By monitoring these pressures, operators can ensure that the train operates at peak efficiency.

4. Preventive Maintenance: Regular monitoring of pressure levels can aid in preventive maintenance. By keeping track of pressure readings over time, maintenance teams can identify trends that may indicate wear and tear or potential failures. This proactive approach allows for timely repairs and replacements, reducing the risk of unexpected breakdowns and costly downtime.

5. Compliance with Regulations: The railway industry is heavily regulated, with strict standards for safety and performance. Pressure gauges help operators comply with these regulations by providing the necessary data to demonstrate that systems are functioning within acceptable parameters. This is particularly important during inspections and audits.

6. Data Collection and Analysis: Modern railway pressure gauges often come equipped with digital displays and data logging capabilities. This allows for the collection of historical data, which can be analyzed to improve operational practices. By understanding pressure trends, railway companies can make informed decisions about system upgrades, maintenance schedules, and operational protocols.

In conclusion, railway pressure gauges are indispensable tools in the railway industry, serving multiple functions that enhance safety, efficiency, and compliance. By continuously monitoring pressure levels, these gauges provide critical information that helps operators maintain optimal performance and prevent potential failures. As technology advances, the role of pressure gauges will likely evolve, incorporating more sophisticated features that further enhance their functionality. For anyone involved in railway operations, understanding the function of railway pressure gauges is essential for ensuring the safe and efficient transport of goods and passengers alike.

What Is A Railway Pressure Gauge?

In the intricate world of railway operations, precision and safety are paramount. One of the critical components that ensure the smooth functioning of railway systems is the railway pressure gauge. This instrument plays a vital role in monitoring the pressure levels within various systems, including braking and hydraulic systems. Understanding the common gauges used in railways, including the railway pressure gauge, is essential for maintaining operational efficiency and safety.

A railway pressure gauge is a device designed to measure the pressure of fluids within railway systems. It provides real-time data that is crucial for the safe operation of trains. These gauges are typically used in various applications, including air brake systems, fuel systems, and hydraulic systems. By monitoring pressure levels, railway personnel can ensure that systems are functioning within safe parameters, preventing potential failures that could lead to accidents.

Common Gauges Used in Railways

1. Pressure Gauges: As mentioned, railway pressure gauges are among the most critical instruments in railway operations. They are used to monitor the pressure of air in brake systems, ensuring that trains can stop safely and efficiently. These gauges can be analog or digital, with digital gauges providing more precise readings and often featuring alarms for pressure anomalies.

2. Temperature Gauges: Temperature gauges are essential for monitoring the heat levels in various components of a train, such as engines and bearings. Overheating can lead to mechanical failures, making these gauges vital for preventive maintenance. They help in ensuring that the train operates within the optimal temperature range, thereby enhancing safety and performance.

3. Speed Gauges: Speed gauges, or speedometers, are crucial for monitoring the speed of trains. They provide real-time feedback to the train operator, allowing for adjustments to be made to maintain safe speeds, especially in areas with speed restrictions. Accurate speed measurement is essential for adhering to safety regulations and ensuring passenger safety.

4. Fuel Gauges: Fuel gauges are used to monitor the fuel levels in locomotives. These gauges help operators manage fuel consumption effectively, ensuring that trains do not run out of fuel during operations. They are particularly important for long-haul trains, where fuel management can significantly impact operational efficiency.

5. Vacuum Gauges: In some railway systems, particularly those using vacuum brakes, vacuum gauges are employed to measure the vacuum pressure in the braking system. This is crucial for ensuring that the brakes function correctly, as insufficient vacuum pressure can lead to brake failure.

6. Load Gauges: Load gauges are used to monitor the weight and load distribution on railway cars. This information is vital for ensuring that trains are not overloaded, which can lead to safety hazards and increased wear on tracks and rolling stock.

In conclusion, railway pressure gauges are an integral part of the railway system, providing essential data that helps maintain safety and efficiency. Alongside pressure gauges, various other gauges, including temperature, speed, fuel, vacuum, and load gauges, play significant roles in the overall operation of trains. Understanding these common gauges and their functions is crucial for railway professionals, as it enables them to make informed decisions that enhance safety and operational effectiveness. As technology continues to advance, the accuracy and reliability of these gauges will only improve, further contributing to the safety and efficiency of railway systems worldwide.