أغسطس . 15, 2024 10:10 Back to list

Exploring Quotes for Metallic Diaphragm Pressure Gauges and Their Applications in Various Industries

Understanding Metallic Diaphragm Pressure Gauge Quotes

Pressure gauges are essential instruments employed across various industries to measure the pressure of liquids and gases. Among the different types of pressure gauges available, metallic diaphragm pressure gauges are renowned for their precision, reliability, and durability. As industries increasingly rely on efficient monitoring systems, understanding the nuances of metallic diaphragm pressure gauges, including their specifications and associated quotes, is crucial for making informed purchasing decisions.

What is a Metallic Diaphragm Pressure Gauge?

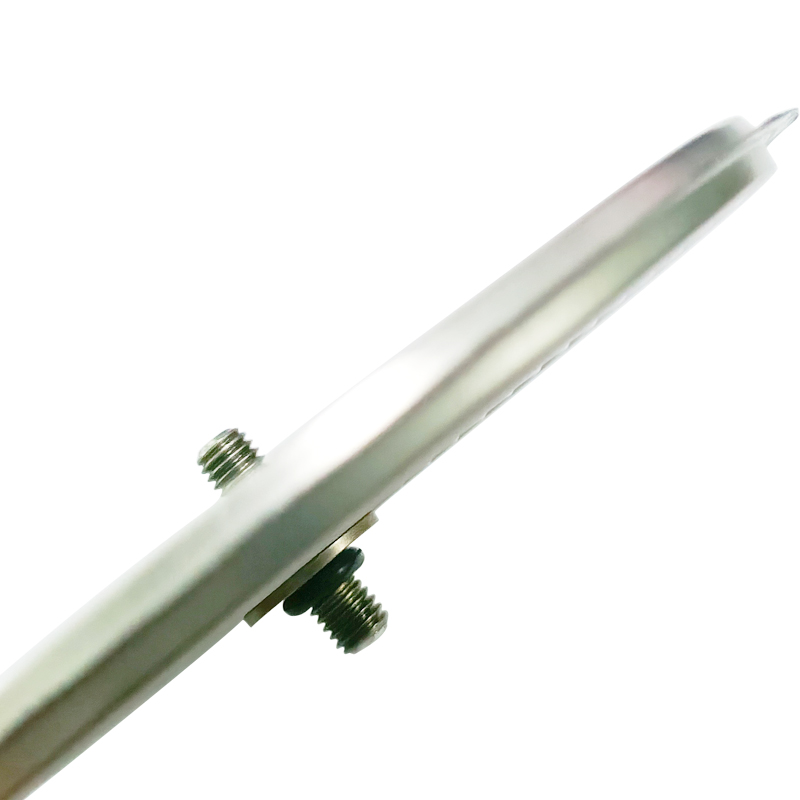

A metallic diaphragm pressure gauge operates by utilizing a metallic diaphragm that deforms under pressure changes. This diaphragm, typically made from stainless steel or other robust materials, is hermetically sealed to ensure that external factors do not affect the readings. The diaphragm's deflection is directly proportional to the pressure exerted, which is then translated into readable measurements on the gauge’s dial.

These gauges are particularly favored in high-pressure applications due to their ability to withstand severe conditions without compromising accuracy. They are commonly used in industries such as oil and gas, chemical processing, pharmaceuticals, and food and beverage, where precise pressure readings are vital for safety and operational efficiency.

Factors Influencing Quotes for Metallic Diaphragm Pressure Gauges

When seeking quotes for metallic diaphragm pressure gauges, several factors come into play

1. Material Quality The choice of material significantly impacts durability and resistance to corrosive substances. Stainless steel, for instance, is a popular choice due to its exceptional strength and resistance to oxidation.

2. Pressure Range Different applications require different pressure ranges. Gauges are available with varying measurement capabilities, and selecting the appropriate range affects the overall cost.

3. Size and Fit The size of the gauge must fit the specific application requirements. Larger dials may provide greater visibility but can also influence the price.

metallic diaphragm pressure gauge quotes

4. Connection Type The connection type (threaded, sanitary, flanged, etc.) determines how the gauge will be installed in existing systems, impacting both compatibility and cost.

5. Calibration and Accuracy Higher accuracy gauges often come at a premium. Custom calibration options may also add to the overall expense.

6. Quantity Ordered Bulk purchases typically lead to discounts, making it beneficial for companies to evaluate their needs and order accordingly.

7. Brand and Warranty Established brands with a reputation for quality may charge more, yet the assurance of reliability can justify the investment. Additional services, including warranties and customer support, can also affect quoted prices.

How to Approach Quotes

When acquiring quotes for metallic diaphragm pressure gauges, it is advisable to gather estimates from multiple suppliers to ensure competitive pricing. It is essential to provide prospective suppliers with detailed specifications regarding the intended application and desired features. This clarity will enable suppliers to tailor their quotes more accurately.

Additionally, engaging with suppliers regarding their recommendations and any potential discounts for long-term agreements or bulk orders can lead to more favorable pricing. Always consider the total cost of ownership, including maintenance and operational longevity, rather than solely focusing on the initial purchase cost.

Conclusion

Metallic diaphragm pressure gauges play a critical role in various sectors, providing reliability and precision in pressure measurement. By understanding the factors that influence quotes and by approaching suppliers with clear requirements, organizations can optimize their purchasing decisions. Ultimately, investing in high-quality pressure gauges is not just a matter of meeting regulatory standards but is also vital for safeguarding operational efficiency and ensuring safety in industrial processes.

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025

-

Wika Diaphragm Seal Pressure Gauge High-Accuracy & Durable Solutions

NewsMay.18,2025

-

Diaphragm Type Differential Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.17,2025