أغسطس . 17, 2024 12:55 Back to list

Exporter of Capillary Type Differential Pressure Gauges for Precision Measurement Solutions

Capillary Type Differential Pressure Gauge Exporter Enhancing Measurement Precision

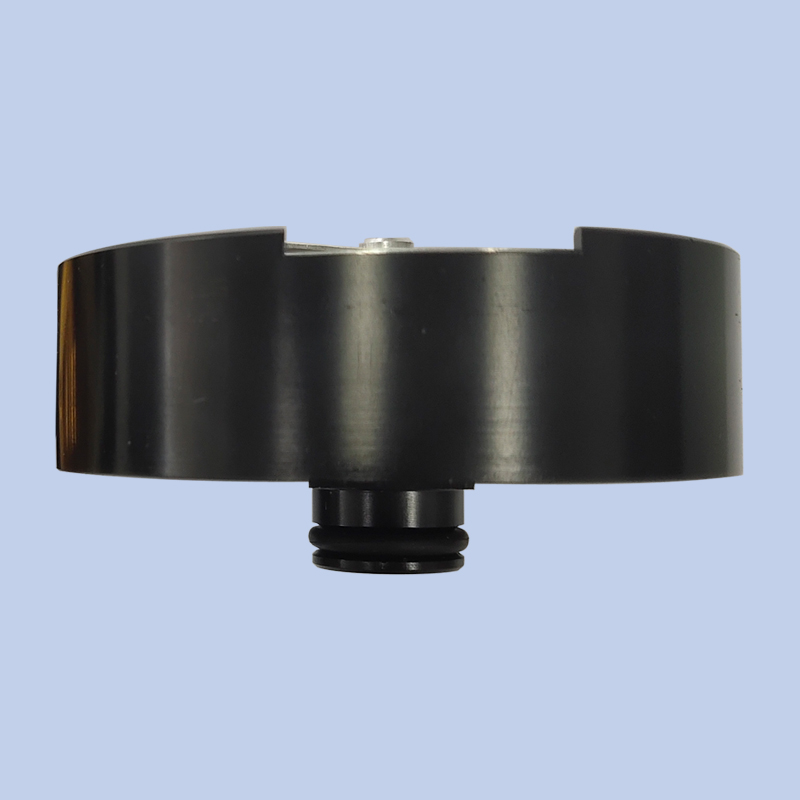

In the field of industrial measurement and instrumentation, the capillary type differential pressure gauge stands out as a vital tool for ensuring precision and reliability. These gauges are used widely across various industries, including oil and gas, chemical manufacturing, and HVAC systems, to monitor pressure differences in liquids and gases. As a growing exporter of capillary type differential pressure gauges, it is essential to understand their importance, functionality, and market demand.

Understanding Capillary Type Differential Pressure Gauges

Capillary type differential pressure gauges utilize the principle of liquid column balance to measure the difference in pressure between two points. The gauge consists of a sensing element, typically a capillary tube filled with a fluid, that connects two separate pressure points. The pressure difference causes the fluid within the capillary to move, indicating the pressure differential on a calibrated dial.

These gauges are valued for their accuracy, durability, and low maintenance requirements. The use of a capillary tube allows for extended reach to hard-to-access measurement points, making them ideal for applications that require long-distance measurement without the need for complex installations.

Key Features and Advantages

1. High Accuracy and Stability Capillary type differential pressure gauges are known for their high degree of accuracy. They can measure small pressure changes, which is crucial in processes where even slight deviations can lead to significant consequences.

2. Chemical Compatibility The materials used in the construction of these gauges are often resistant to a variety of chemicals, which makes them suitable for harsh environments. This durability ensures long-term performance and reduces the need for frequent replacements.

capillary type differential pressure gauge exporter

3. Temperature Resistance Many capillary type gauges are designed to operate effectively over a wide temperature range, maintaining their accuracy in extreme conditions.

4. Easy Installation Their relatively simple design allows for straightforward installation and integration into existing systems, minimizing downtime and labor costs for industries.

5. Cost-Effectiveness Over time, the reliability and low maintenance needs of capillary type differential pressure gauges can result in lower operational costs, making them a cost-effective solution for pressure measurement.

Market Demand and Export Opportunities

With the increasing emphasis on safety, efficiency, and environmental compliance in industries worldwide, the demand for accurate pressure measurement solutions has risen significantly. Emerging markets in Asia-Pacific and Latin America are particularly promising, as industrialization and modernization drive the need for advanced measurement systems.

As an exporter of capillary type differential pressure gauges, it is crucial to stay attuned to global trends and customer needs. Adapting products to meet regulatory standards in different regions, such as ISO certifications or local safety standards, can enhance marketability. Furthermore, building strong relationships with distributors and end-users in target markets can facilitate smoother entry and expansion.

Conclusion

The capillary type differential pressure gauge is an indispensable tool in various industries, ensuring the accuracy and reliability needed for effective process management. As an exporter, understanding the features, advantages, and market dynamics of these gauges can significantly enhance business opportunities. By focusing on quality, compliance, and customer relationships, exporters can carve a niche in the global market and contribute to improved industrial performance worldwide. Investing in research and development will also keep products ahead of the competition, ensuring sustained growth and success in the evolving landscape of industrial measurement.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025