أغسطس . 28, 2024 21:26 Back to list

Famous Bourdon Type Differential Pressure Gauge - Precision and Reliability

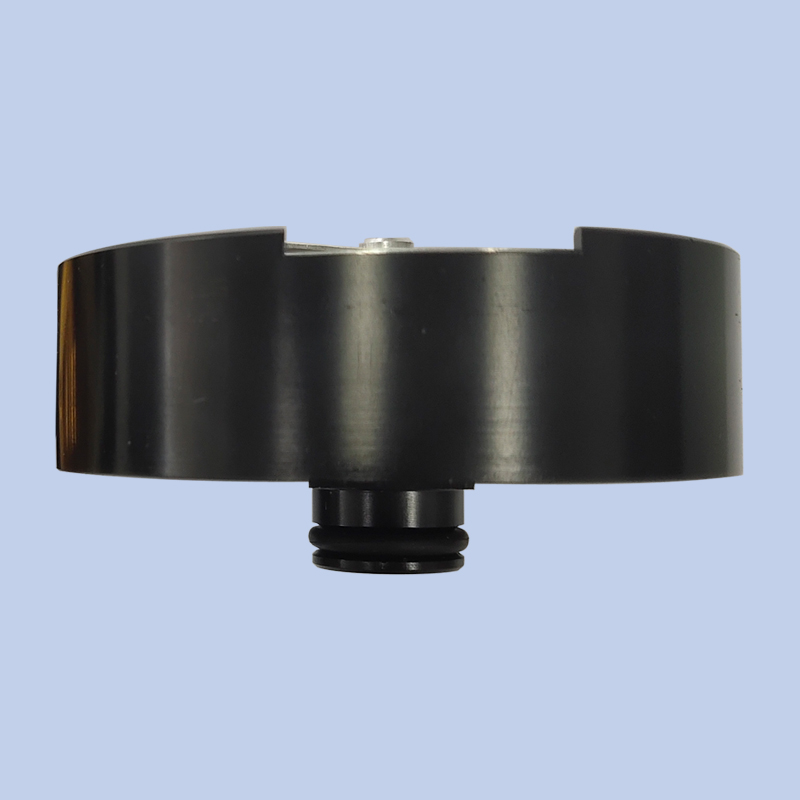

The Famous Bourdon Type Differential Pressure Gauge

The Bourdon type differential pressure gauge is a crucial instrument widely utilized in various industries to measure pressure differences between two points in a system. Its unique design and operational principles make it reliable, accurate, and robust for numerous applications, from oil and gas to HVAC systems.

Working Principle

The Bourdon gauge operates based on the principle of elastic deformation. It consists of a curved tube, typically made of brass or stainless steel, which straightens when subjected to pressure. In the case of a differential pressure gauge, two pressures are applied at either end of the Bourdon tube, and the difference in these pressures causes the tube to deform. This deformation is then translated into a rotational movement of a pointer, which indicates the pressure difference on a calibrated dial.

Construction and Design

The distinctive design of the Bourdon tube is pivotal to its operation. The tube's curvature means that any change in pressure leads to a proportional movement that can be easily read on a scale. Differential pressure gauges often include additional features such as internal dampening mechanisms, which help to minimize the effects of pulsations or vibrations in the medium being measured. The durability and mechanical simplicity of the Bourdon type gauge make it especially advantageous in harsh operating conditions.

famous bourdon type differential pressure gauge

Applications

Bourdon type differential pressure gauges find applications in a variety of fields. In the oil and gas industry, they are used to monitor the pressure across filters and separators, ensuring efficient operation and preventing damage from pressure fluctuations. In HVAC systems, these gauges are essential for checking air filter pressure drop, which helps in maintaining optimal airflow and energy efficiency. Furthermore, they are employed in water treatment facilities to monitor pressure variations that could indicate leaks or blockages.

Advantages

One of the significant advantages of Bourdon type differential pressure gauges is their reliability. They require minimal maintenance, and their mechanical nature does not depend on external power sources, making them suitable for remote locations. Additionally, they are known for their accuracy and response time, providing real-time data that is critical for process control.

Conclusion

The Bourdon type differential pressure gauge is an exemplary embodiment of mechanical engineering and design that has stood the test of time. Its simplicity, reliability, and versatility make it an indispensable tool in a diverse array of applications. As industries continue to evolve, the demand for accurate pressure measurement will persist, ensuring the ongoing relevance of the Bourdon gauge in modern engineering practices.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025