أغسطس . 14, 2024 19:24 Back to list

Manufacturers of Custom Pressure Gauge Diaphragm Seals for Industrial Applications and Solutions

Understanding Custom Pressure Gauge Diaphragm Seal Manufacturers

In various industrial applications, precision and reliability in pressure measurement are critical. Custom pressure gauges equipped with diaphragm seals play a significant role in ensuring accurate readings while providing protection against harsh environments. This article delves into the importance of diaphragm seals, their manufacturers, and how they contribute to the overall effectiveness of pressure measurement devices.

The Role of Diaphragm Seals

A diaphragm seal is a mechanical device that separates the pressure measuring instrument from the process fluid. This separation is essential when dealing with corrosive, viscous, or high-temperature fluids that could damage the pressure gauge. By employing a diaphragm seal, the gauge is protected, ensuring that it continues to provide accurate readings over time.

Diaphragm seals are typically made of materials such as stainless steel, Hastelloy, or Teflon, which can withstand chemical exposure and high pressures. The diaphragm itself is a flexible membrane that deforms under pressure, transmitting the force to the gauge while isolating it from the process media. This design not only enhances the durability of the device but also expands its range of applications.

The Importance of Custom Solutions

Not all applications have the same requirements, which is where custom diaphragm seals come into play. Custom manufacturers of pressure gauge diaphragm seals can design and produce seals tailored to specific applications. This customization includes adjustments to the size, material, and configuration of the diaphragm seal, ensuring compatibility with various types of fluids and environmental conditions.

For industries such as oil and gas, pharmaceuticals, and food processing, the ability to customize diaphragm seals is crucial. For instance, a food processing facility may need seals that comply with food safety standards, while a chemical plant might require seals that resist specific corrosive substances. Custom manufacturers offer the flexibility to meet these diverse needs efficiently.

Selecting the Right Manufacturer

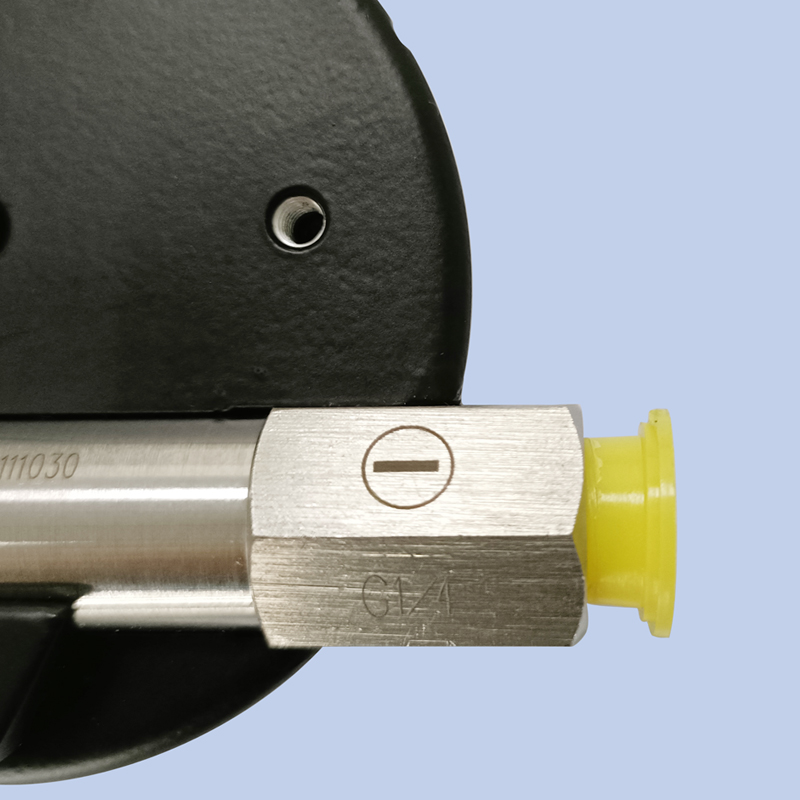

custom pressure gauge diaphragm seal manufacturers

Choosing a reputable custom pressure gauge diaphragm seal manufacturer is essential for ensuring quality and reliability. Here are some factors to consider when selecting a manufacturer

1. Experience and Expertise Look for manufacturers with a proven track record in producing diaphragm seals for a variety of industries. Their experience can provide valuable insights into the best materials and designs for specific applications.

2. Quality Standards Manufacturers should adhere to international quality standards such as ISO 9001. Certifications indicate that they maintain rigorous quality control processes throughout production.

3. Technical Support A good manufacturer will offer technical assistance, helping customers select the right seal for their application and providing guidance on installation and maintenance.

4. Customization Capabilities Assess the manufacturer’s ability to create bespoke solutions. This includes not only the design but also the capability to produce low to high quantities based on demand.

5. Customer Reviews Researching customer feedback can offer insights into the reliability and performance of the manufacturer’s products. Testimonials and case studies can highlight their successful applications in real-world scenarios.

Conclusion

Custom pressure gauge diaphragm seal manufacturers play a fundamental role in ensuring the accuracy and reliability of pressure measurement devices across various industries. By providing tailored solutions that address specific challenges, these manufacturers enhance the overall performance of pressure monitoring systems. As industrial processes become more complex, the demand for specialized diaphragm seals will continue to grow, highlighting the importance of selecting the right manufacturer to meet these evolving needs. Investing in quality diaphragm seals not only safeguards the integrity of the pressure measurement but also contributes to the efficiency and safety of industrial operations.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025