أكتوبر . 09, 2024 10:58 Back to list

odm diaphragm vacuum pressure gauge

Understanding ODM Diaphragm Vacuum Pressure Gauges

In the realm of industrial measurements, precision matters immensely. Among the various tools used for measuring pressure, diaphragmatic vacuum pressure gauges stand out for their accuracy and reliability. This article delves into the workings and applications of ODM diaphragm vacuum pressure gauges, exploring their features, benefits, and versatility in various industries.

What is a Diaphragm Vacuum Pressure Gauge?

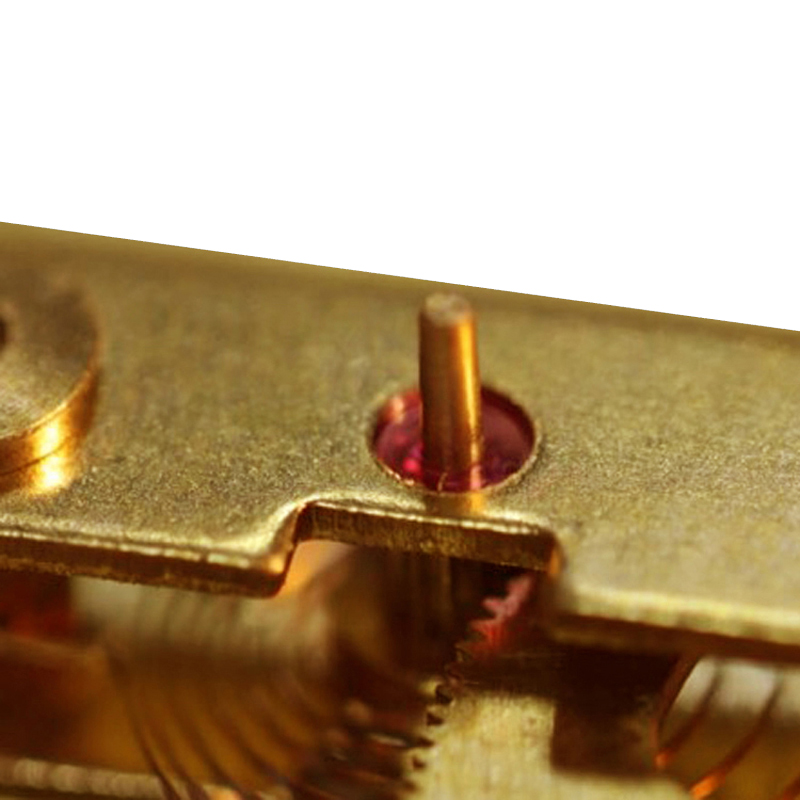

A diaphragm vacuum pressure gauge is a device designed to measure the pressure of gases below atmospheric pressure, particularly in vacuum applications. Unlike traditional gauges that operate primarily on the principle of fluid dynamics, the diaphragm gauge uses a flexible membrane (the diaphragm) to detect pressure changes. This diaphragm moves in response to pressure variations, translating mechanical motion into an easily readable measurement on a calibrated dial or display.

The Role of ODM in Vacuum Technology

ODM, or Original Design Manufacturer, refers to companies that design and manufacture products that can be sold under another company's brand. In the context of diaphragm vacuum pressure gauges, ODMs are crucial in providing innovative designs and high-quality components, ensuring that these gauges meet the performance needs of diverse industries.

Key Features of ODM Diaphragm Vacuum Pressure Gauges

1. High Sensitivity and Accuracy One of the hallmark features of ODM diaphragm vacuum pressure gauges is their high sensitivity. Due to the design of the diaphragm, these gauges can detect even slight pressure changes, making them ideal for applications where precision is critical.

2. Durable Construction ODM gauges are often built using high-quality materials resistant to corrosion and wear. This durability extends the lifespan of the gauges, making them suitable for harsh environments often encountered in industrial settings.

3. Wide Measurement Range ODM diaphragm vacuum pressure gauges are versatile, capable of measuring a broad range of vacuum pressures. This flexibility allows them to be employed in various applications, from scientific research to heavy industry.

4. Compact Design Many ODM models emphasize compactness, making them easy to integrate into existing systems without requiring significant modifications or extra space. Their small footprint is particularly beneficial in environments where equipment is densely packed.

5. Easy Calibration and Maintenance Regular calibration is essential for maintaining the accuracy of pressure gauges. ODM diaphragm vacuum pressure gauges are often designed for straightforward calibration processes, making it easier for operators to ensure ongoing accuracy without extensive downtime.

odm diaphragm vacuum pressure gauge

Applications of ODM Diaphragm Vacuum Pressure Gauges

1. Semiconductor Manufacturing

In semiconductor fabrication, precise vacuum conditions are essential for processes like chemical vapor deposition (CVD) and physical vapor deposition (PVD). ODM diaphragm vacuum pressure gauges are employed to monitor and control vacuum levels, ensuring optimal conditions for delicate manufacturing processes.

2. Pharmaceuticals

The pharmaceutical industry often requires vacuum environments for various processes, including freeze-drying and aseptic packaging. The reliability and accuracy of ODM diaphragm gauges contribute to maintaining the integrity of drug production.

3. Food Processing

Vacuum technology is gaining traction in food processing, particularly in packaging and preservation methods like vacuum sealing. The durability and adaptability of ODM diaphragm pressure gauges ensure they can handle the demands of food industry applications.

4. Laboratories

In laboratory settings, precise pressure measurements are necessary for various experiments and process validations. The high sensitivity of ODM diaphragm vacuum gauges makes them a reliable choice for researchers needing accurate data to support their findings.

Conclusion

ODM diaphragm vacuum pressure gauges represent a crucial element in modern industrial applications where vacuum environments are essential. Their combination of sensitivity, durability, and ease of use makes them indispensable tools across various sectors, from semiconductor fabrication to food processing. As industries continue to evolve, the demand for precise and reliable pressure measurement solutions will only increase, solidifying the role of ODM diaphragm vacuum pressure gauges in ensuring operational excellence.

In summary, whether you're in research, manufacturing, or quality control, understanding the capabilities and applications of these gauges can enhance your operational efficiency and product quality while ensuring compliance with industry standards.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025