ديسمبر . 03, 2024 17:01 Back to list

Optimizing ODM Flush Diaphragm Pressure Gauge Performance for Accurate Measurements

Understanding ODM Flush Diaphragm Pressure Gauges

In the world of industrial and process measurement, pressure gauges play a crucial role in ensuring systems operate safely and efficiently. Among the various types available, the ODM flush diaphragm pressure gauge stands out for its unique design and effectiveness in handling a wide array of applications. This article delves into the features, applications, and advantages of using ODM flush diaphragm pressure gauges, providing a comprehensive understanding of their significance in different industries.

What is a Flush Diaphragm Pressure Gauge?

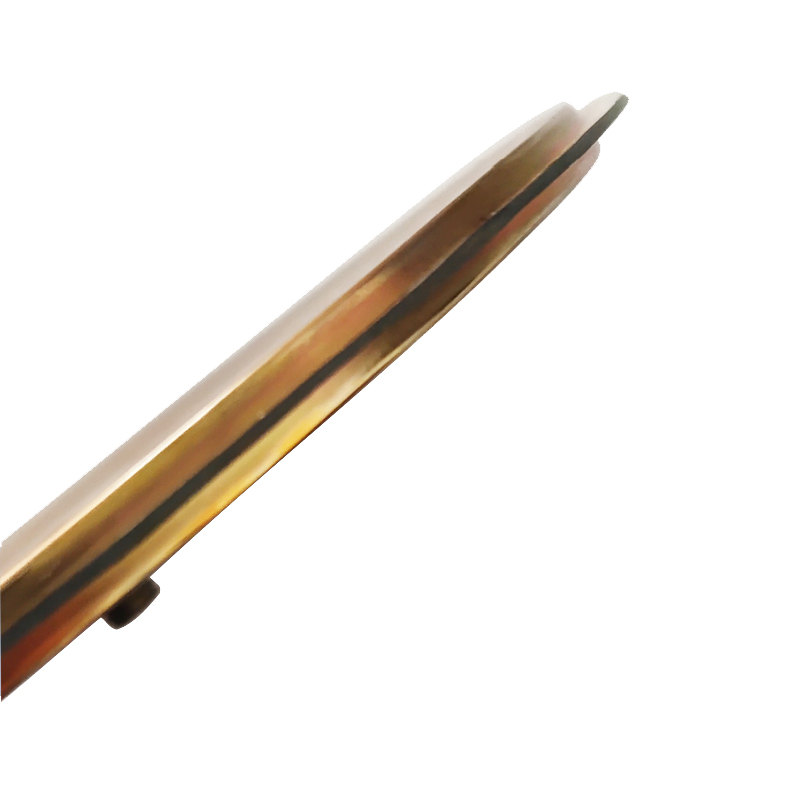

A flush diaphragm pressure gauge is a specialized instrument designed to measure pressure in systems where traditional gauges may be ineffective. The key feature of a flush diaphragm gauge is its flat, flush-mounted diaphragm that separates the pressure sensing element from the process fluid. This design allows for direct contact with the process medium without the need for a traditional pressure port, eliminating the risk of clogging and allowing for easy cleaning.

The ODM (Original Design Manufacturer) variant emphasizes quality and reliability, featuring advanced materials and construction techniques that ensure durability and precision in pressure measurement.

Key Features

1. Sanitary Design The flush diaphragm gauge is particularly popular in industries such as food and beverage, pharmaceuticals, and biotechnology, where cleanliness and hygiene are paramount. Its design prevents contamination, making it ideal for sanitary applications.

2. Clog-Free Operation One of the significant advantages of these gauges is their ability to operate without being susceptible to clogs. The flush diaphragm design allows for a smooth transition of fluids, making it effective in applications with viscous or particulate-laden media.

3. Versatile Material Options ODM flush diaphragm gauges can be constructed from various materials such as stainless steel, Hastelloy, and others suitable for corrosive environments. This versatility allows them to be used in a wide range of applications, from harsh chemicals to foodstuffs.

4. Accurate Readings These pressure gauges are designed to deliver high accuracy and reliability, ensuring that measurements are consistent and precise. This is vital in processes where pressure changes can significantly impact product quality and safety.

Applications

Flush diaphragm pressure gauges are used in numerous industries due to their unique advantages. Some common applications include

odm flush diaphragm pressure gauge

- Food and Beverage Processing In this sector, maintaining product integrity is essential. The flush design prevents bacterial growth and contamination, ensuring that the process remains hygienic.

- Pharmaceutical Manufacturing Similar to the food industry, pharmaceutical processes require stringent hygiene standards

. The ODM flush diaphragm pressure gauge ensures that pressure measurements are taken without the risk of contamination, enabling compliance with industry regulations.- Oil and Gas In the extraction and refining processes, these gauges can handle various materials, including corrosive chemicals, ensuring safe and efficient operations.

- Chemical Processing For environments with high pressures and aggressive media, flush diaphragm gauges provide reliable readings without the need for extensive maintenance.

Advantages

Using ODM flush diaphragm pressure gauges offers a multitude of benefits

- Reduced Maintenance The clog-free operation means less downtime for cleaning and maintenance, enhancing productivity.

- Improved Safety By eliminating the risks associated with traditional gauges, such as leaks and contamination, these gauges contribute to a safer work environment.

- Cost-Effectiveness While there may be an initial investment in purchasing a flush diaphragm gauge, the reduction in maintenance and increased reliability often results in overall cost savings in industrial applications.

Conclusion

In conclusion, ODM flush diaphragm pressure gauges are a vital tool in modern industrial applications, combining precision, safety, and versatility. Their unique design caters to various sectors that require reliable pressure measurements without the complications associated with traditional gauges. As industries increasingly prioritize cleanliness and efficiency, the demand for such advanced measurement technologies is likely to grow, reinforcing the importance of understanding and utilizing solutions such as ODM flush diaphragm pressure gauges in diverse applications.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025