سبتمبر . 22, 2024 19:00 Back to list

precision digital pressure gauges factory

Precision Digital Pressure Gauges A Comprehensive Overview of the Factory Experience

In today’s highly technical landscape, precision digital pressure gauges play a crucial role across various industries, including manufacturing, automotive, and HVAC systems. These devices provide accurate pressure measurements, which are essential for maintaining operational efficiency and ensuring safety. The manufacturing process of precision digital pressure gauges in specialized factories is a blend of advanced technology, skilled craftsmanship, and rigorous quality control.

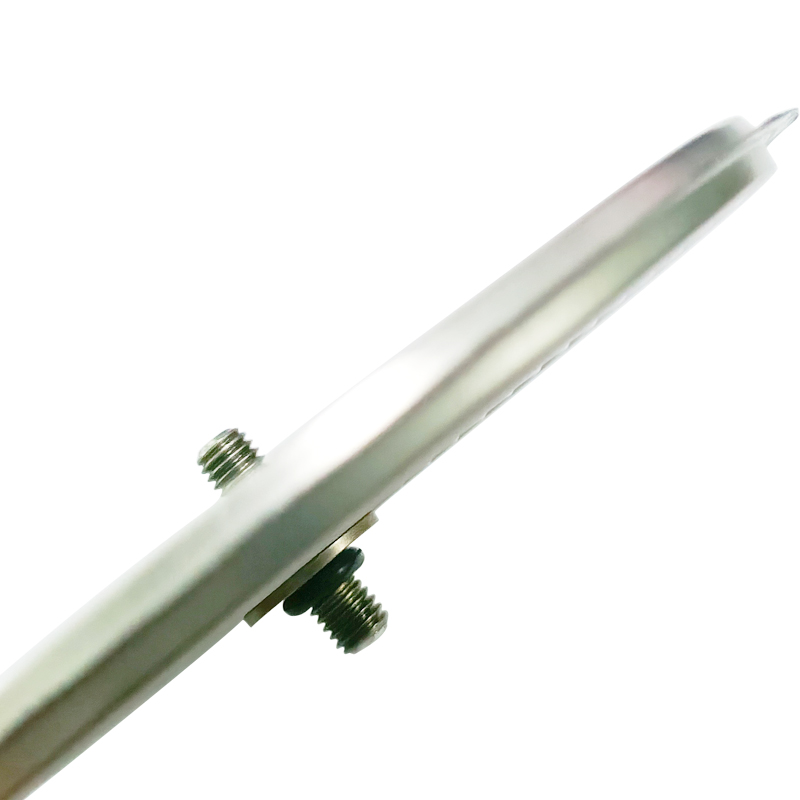

Factories that produce precision digital pressure gauges are equipped with state-of-the-art machinery and utilize high-quality materials. The process begins with the selection of components, which typically include high-precision sensors, digital displays, and durable casings. Each component undergoes a strict quality assessment to ensure that it meets the required specifications.

Once the components are ready, the assembly process begins. Skilled technicians meticulously assemble each gauge, ensuring proper connections and calibrations. Calibration is a critical step in the production of precision digital pressure gauges, as it guarantees that the measurements are accurate. This often involves comparing the gauge against standard reference instruments and making necessary adjustments to ensure optimal performance.

precision digital pressure gauges factory

After assembly, the gauges undergo a series of rigorous testing procedures. This includes pressure cycling tests and environmental assessments to simulate real-world conditions. The aim is to ensure that the digital pressure gauges can withstand varying atmospheric pressures and temperatures while maintaining accuracy. These tests are crucial for establishing the reliability of the gauges in demanding applications.

Quality control does not end with testing; it is an ongoing commitment throughout the manufacturing process. Factories implement comprehensive quality management systems to monitor every aspect of production. This continuous assessment helps identify any potential issues early on and enhances the overall quality of the final product.

Additionally, many factories are adapting to Industry 4.0 principles, integrating smart technologies into their manufacturing processes. This includes the use of IoT devices for real-time monitoring and data analytics, which can optimize production efficiency and reduce waste.

In conclusion, the factory environment dedicated to producing precision digital pressure gauges combines cutting-edge technology, skilled craftsmanship, and stringent quality control measures. As industries continue to evolve, the demand for accurate and reliable pressure measurement tools will only grow, reinforcing the critical role of these factories in meeting that demand. By adhering to high standards of precision and quality, digital pressure gauges manufactured in these settings are poised to support a wide array of applications across diverse sectors.

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025