ديسمبر . 31, 2024 09:28 Back to list

Diaphragm Pressure Gauge Types and Their Applications in Various Industries

Pressure Gauge Diaphragm Type

Pressure gauges are critical instruments used in various industries to measure and monitor pressure levels in different systems. Among the various designs available, the diaphragm type pressure gauge stands out due to its reliability, accuracy, and versatility in application. This article will explore the working principle, advantages, applications, and maintenance of diaphragm type pressure gauges.

Working Principle

The diaphragm pressure gauge operates using a flexible diaphragm that deflects in response to pressure changes. When pressure is applied to one side of the diaphragm, it causes the diaphragm to bend or flex. This movement is proportional to the pressure change and is measured with a mechanical or electronic system. Typically, a mechanical linkage or a transducer is used to convert the diaphragm’s movement into a readable pressure value on the dial or screen of the gauge.

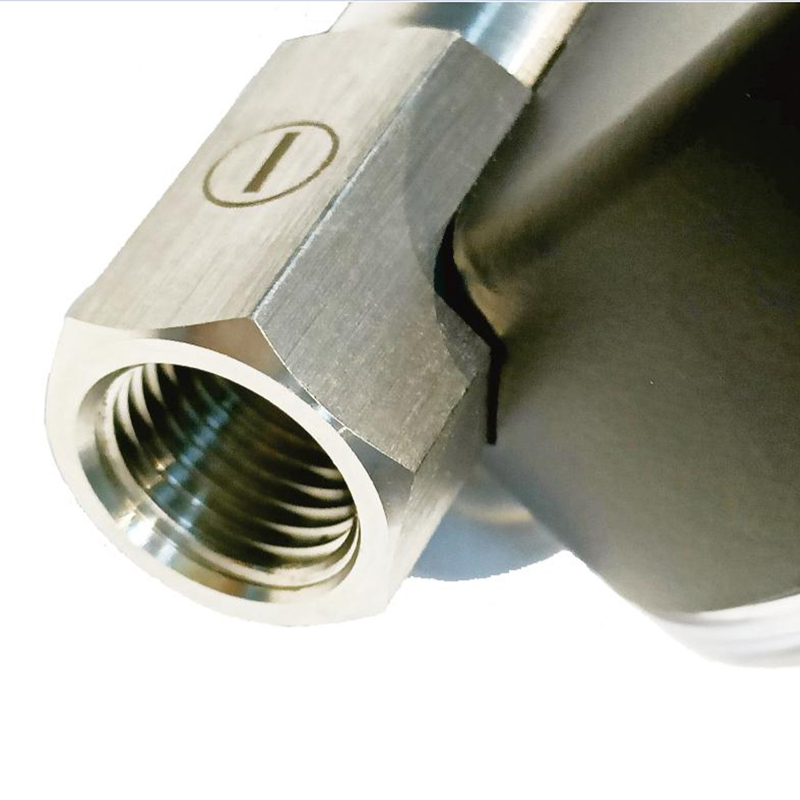

The construction of the diaphragm is crucial; it is typically made of metal or elastomeric materials that can withstand high pressures and corrosive environments. The materials used significantly affect the gauge's durability and reliability, making careful selection essential for the specific application.

Advantages

One of the key advantages of diaphragm type pressure gauges is their ability to measure low-pressure levels with great precision. They can effectively operate in applications that require accurate pressure readings even with fluctuating levels. Additionally, diaphragm gauges have a relatively simple construction, which makes them easy to install and maintain.

Another benefit is their resistance to corrosive environments. Depending on the materials used, diaphragm gauges can be suitable for gases, liquids, and even aggressive media. This versatility makes them ideal for various applications in industries such as petrochemical, food and beverage, pharmaceutical, and water treatment.

Furthermore, diaphragm type gauges are known for their good temperature responsiveness. They can also be designed to handle high temperatures and pressures, which further expands their applicability in demanding conditions.

pressure gauge diaphragm type

Applications

Diaphragm type pressure gauges are utilized in a variety of sectors. In the oil and gas industry, they are employed to monitor the pressure of pipelines and storage tanks. In the food and beverage sector, they can measure the pressure of ingredients in process systems, ensuring product safety and quality.

In pharmaceuticals, precision in pressure measurement is essential for compliance with regulations and safety protocols, making diaphragm gauges the preferred choice. Additionally, they are commonly used in HVAC systems to monitor air and gas pressures, ensuring efficient system performance.

Maintenance

Regular maintenance is key to ensuring the longevity and accuracy of diaphragm type pressure gauges. It is essential to periodically inspect the gauge for any signs of wear, corrosion, or leakage. Calibrating the gauge at regular intervals will help maintain accuracy over time.

The installation process should also be approached with care; gauges should be mounted correctly to avoid unnecessary stress on the diaphragm, which can lead to premature failure. Proper filtering should be employed to prevent particulates from damaging the diaphragm, especially in environments where the media may contain debris.

Conclusion

Diaphragm type pressure gauges are invaluable instruments across a multitude of industries due to their accurate pressure measurement capabilities, robustness, and versatility. Understanding their working principle, advantages, applications, and maintenance will enable users to utilize these gauges effectively and ensure their long-term functionality. As technology continues to advance, the design and performance of diaphragm type pressure gauges are likely to evolve, reflecting the growing demands of modern industrial applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025