Feb . 04, 2025 03:33 Back to list

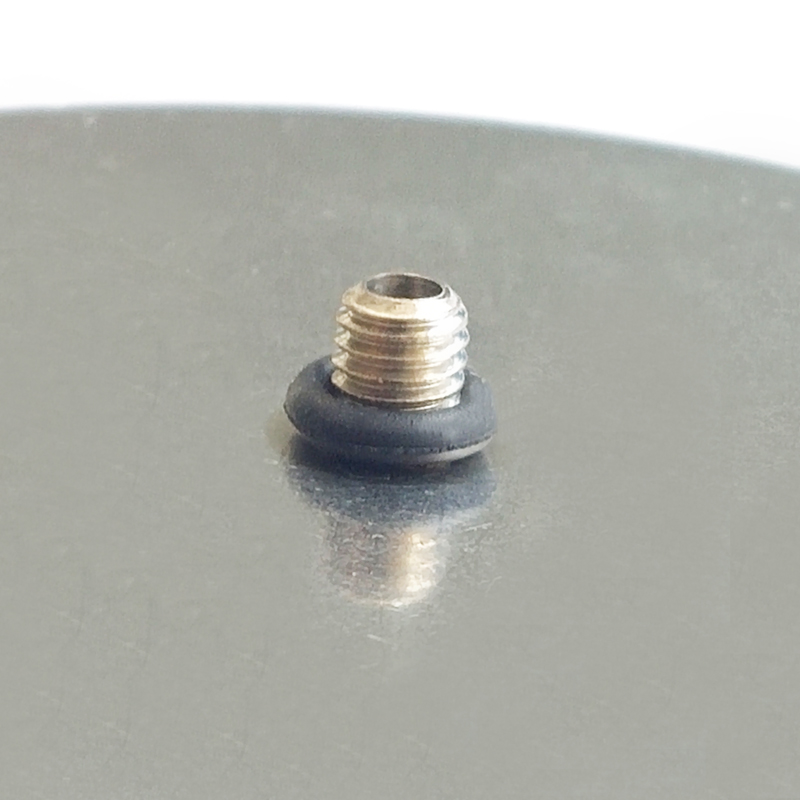

oem diaphragm pressure guage

Choosing the right OEM diaphragm pressure gauge can significantly impact the efficiency and accuracy of your systems. In the highly specialized world of industrial instrumentation, the diaphragm pressure gauge has become a cornerstone for ensuring precise pressure measurements, safeguarding system reliability, and enhancing operational safety. With extensive experience in the field, I have seen how these instruments have evolved to meet the demanding needs of various applications.

Professional expertise is indispensable when selecting diaphragm pressure gauges. An experienced specialist can guide the selection process by helping to specify precise requirements, select appropriate materials, and ensure compatibility with existing systems. This expertise not only optimizes performance but also can save costs in the long run by avoiding equipment failures or the need for replacements. Authoritative suppliers of OEM diaphragm pressure gauges not only provide high-quality products but also offer comprehensive technical support and training. Building a relationship with a reputable supplier can provide invaluable insights and assistance in troubleshooting, installation, and system upgrades. Trustworthiness is also paramount. When data integrity and process control depend on the readings from instruments like diaphragm pressure gauges, having confidence in your supplier’s reliability and the equipment's durability is crucial. Conducting thorough research and reading customer reviews and case studies can help in choosing a supplier with a proven track record. In conclusion, the selection of the right OEM diaphragm pressure gauge involves a comprehensive understanding of the application requirements and the conditions under which the equipment will operate. By aligning with a trustworthy supplier, leveraging professional expertise, and ensuring authoritative support, businesses can optimize the use of diaphragm pressure gauges for accurate pressure measurement, contributing positively to their operational efficiency and system reliability.

Professional expertise is indispensable when selecting diaphragm pressure gauges. An experienced specialist can guide the selection process by helping to specify precise requirements, select appropriate materials, and ensure compatibility with existing systems. This expertise not only optimizes performance but also can save costs in the long run by avoiding equipment failures or the need for replacements. Authoritative suppliers of OEM diaphragm pressure gauges not only provide high-quality products but also offer comprehensive technical support and training. Building a relationship with a reputable supplier can provide invaluable insights and assistance in troubleshooting, installation, and system upgrades. Trustworthiness is also paramount. When data integrity and process control depend on the readings from instruments like diaphragm pressure gauges, having confidence in your supplier’s reliability and the equipment's durability is crucial. Conducting thorough research and reading customer reviews and case studies can help in choosing a supplier with a proven track record. In conclusion, the selection of the right OEM diaphragm pressure gauge involves a comprehensive understanding of the application requirements and the conditions under which the equipment will operate. By aligning with a trustworthy supplier, leveraging professional expertise, and ensuring authoritative support, businesses can optimize the use of diaphragm pressure gauges for accurate pressure measurement, contributing positively to their operational efficiency and system reliability.

Share

Latest news

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025