Jan . 20, 2025 10:48 Back to list

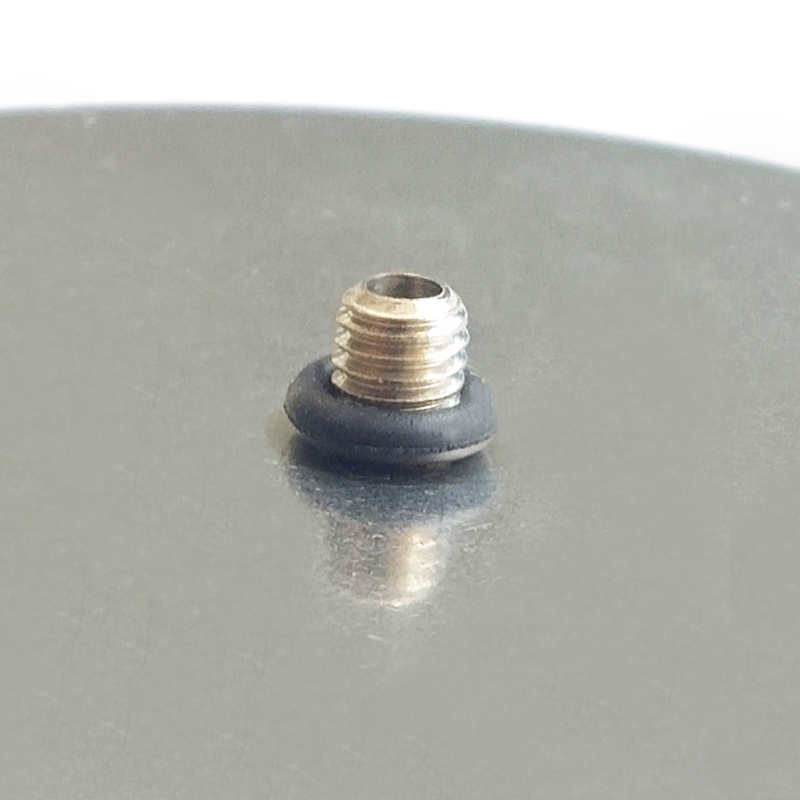

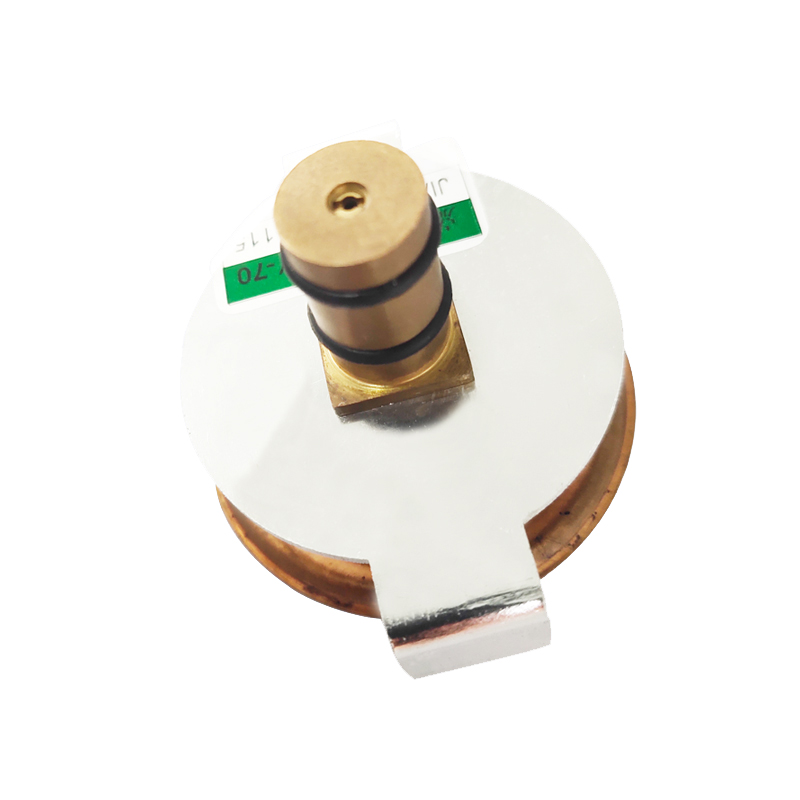

oem differential pressure gauge valve

Differential pressure gauges equipped with a 5 valve manifold provide unparalleled functionality and reliability in industrial settings. These instruments are indispensable in processes where monitoring pressure differentials accurately can mean the difference between smooth operations and catastrophic shutdowns. Understanding the complexities of this equipment can provide invaluable insights into maintaining operational integrity and efficiency.

Many industries rely on the integrity of their pressure systems for safety and compliance reasons. Petroleum, chemical processing, and power generation are prime examples where differential pressure gauges with a 5 valve manifold are vital. In these sectors, fail-proof operation of pressure monitoring systems is crucial not only for efficiency but also for regulatory compliance and environmental protection. Hence, selecting the right equipment designed and tested by reputable manufacturers is critical for meeting these standards. Additionally, technological advancements in instrumentation have led to the development of smart differential pressure gauges. These devices combine the traditional mechanical components with digital interfaces, offering enhanced monitoring capabilities such as remote reading, data logging, and system integration via industrial communication protocols. This evolution allows for more nuanced analysis and predictive maintenance, highlighting potential issues before they escalate into significant problems. For engineers and procurement specialists, choosing the right differential pressure gauge with a 5 valve manifold necessitates a thorough understanding of operational requirements and environmental conditions. Collaboration with experienced vendors can ensure that the selected systems provide optimal performance and reliability. Often, consultation with these experts can uncover opportunities for cost savings and efficiencies through custom solutions or the integration of additional features, such as temperature compensation or overpressure protection. In conclusion, differential pressure gauges with a 5 valve manifold are indispensable tools in maintaining the integrity and efficiency of industrial processes. By combining robust engineering with innovative solutions, they enable precise measurement and control, safeguarding operations across various industries. Investing in high-quality, expertly designed equipment is crucial for sustaining operational success and ensuring system safety in the demanding landscapes of modern industry.

Many industries rely on the integrity of their pressure systems for safety and compliance reasons. Petroleum, chemical processing, and power generation are prime examples where differential pressure gauges with a 5 valve manifold are vital. In these sectors, fail-proof operation of pressure monitoring systems is crucial not only for efficiency but also for regulatory compliance and environmental protection. Hence, selecting the right equipment designed and tested by reputable manufacturers is critical for meeting these standards. Additionally, technological advancements in instrumentation have led to the development of smart differential pressure gauges. These devices combine the traditional mechanical components with digital interfaces, offering enhanced monitoring capabilities such as remote reading, data logging, and system integration via industrial communication protocols. This evolution allows for more nuanced analysis and predictive maintenance, highlighting potential issues before they escalate into significant problems. For engineers and procurement specialists, choosing the right differential pressure gauge with a 5 valve manifold necessitates a thorough understanding of operational requirements and environmental conditions. Collaboration with experienced vendors can ensure that the selected systems provide optimal performance and reliability. Often, consultation with these experts can uncover opportunities for cost savings and efficiencies through custom solutions or the integration of additional features, such as temperature compensation or overpressure protection. In conclusion, differential pressure gauges with a 5 valve manifold are indispensable tools in maintaining the integrity and efficiency of industrial processes. By combining robust engineering with innovative solutions, they enable precise measurement and control, safeguarding operations across various industries. Investing in high-quality, expertly designed equipment is crucial for sustaining operational success and ensuring system safety in the demanding landscapes of modern industry.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025