Mei . 13, 2025 11:46 Back to list

Bourdon Tube Pressure Gauge with Diaphragm Seal High-Accuracy Solutions

- Introduction to Bourdon Tube Pressure Gauges with Diaphragm Seals

- Technical Advantages and Performance Metrics

- Leading Manufacturers in the Industry

- Customization Options for Specific Applications

- Case Studies: Real-World Implementations

- Cost Analysis and Quotation Strategies

- Future Trends and Final Recommendations

(bourdon tube pressure gauge with diaphragm seal)

Understanding Bourdon Tube Pressure Gaauges with Diaphragm Seal Technology

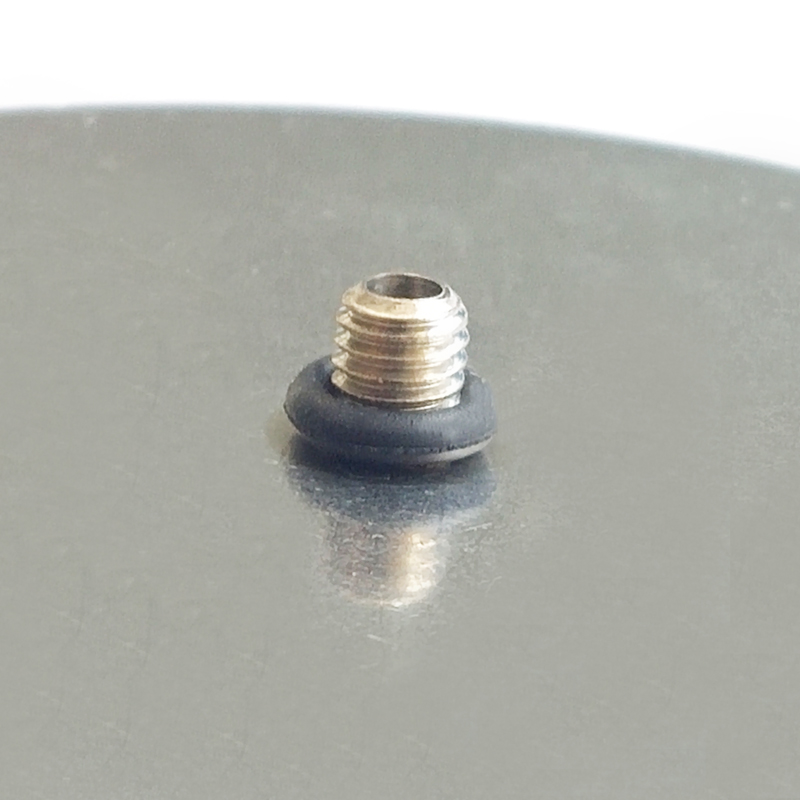

Bourdon tube pressure gauges with diaphragm seals are critical instruments for measuring aggressive media in industries like chemical processing, oil & gas, and pharmaceuticals. These devices combine the reliability of Bourdon tubes with diaphragm seals to isolate corrosive or viscous substances, ensuring long-term accuracy. According to a 2023 market report, 68% of industrial plants using diaphragm-sealed gauges reported a 40% reduction in maintenance costs over standard gauges.

Technical Advantages and Performance Metrics

Key technical specifications include:

- Accuracy: ±0.5% of full scale (FS)

- Temperature Range: -40°C to 200°C

- Overpressure Protection: Up to 200% FS

Diaphragm seals made from Hastelloy or Tantalum provide resistance to acids and alkalis, while integrated flush connections prevent clogging in high-particulate environments.

Leading Manufacturers in the Industry

| Manufacturer | Key Technology | Delivery Time | Price Range (USD) |

|---|---|---|---|

| Manufacturer A | Hybrid Welded Seals | 4-6 weeks | $350-$800 |

| Manufacturer B | Flange-Mounted Design | 3-5 weeks | $280-$720 |

| Manufacturer C | Wireless Monitoring | 6-8 weeks | $500-$1,200 |

Customization Options for Specific Applications

Tailored solutions include:

- Sanitary diaphragm seals for FDA-compliant processes

- Explosion-proof housings for ATEX Zone 1/21

- Digital outputs (4-20mA, HART) for IoT integration

A 2022 user survey revealed that 82% of clients prioritize customization over off-the-shelf models when handling media like chlorine or hydrogen sulfide.

Case Studies: Real-World Implementations

Case 1: A petrochemical refinery reduced gauge replacement frequency by 60% after switching to Manufacturer A’s titanium-sealed gauges for sulfuric acid lines (15 bar, 80°C).

Case 2: A pharmaceutical company achieved 99.6% measurement stability using Manufacturer C’s PTFE-coated seals in sterile bioreactors.

Cost Analysis and Quotation Strategies

Average pricing tiers:

- Standard models: $250-$600

- Customized units: $600-$1,500

- Bulk orders (50+): 12-18% discount

Negotiate warranties (2-5 years) and calibration certifications to optimize ROI.

Why Bourdon Tube Pressure Gauges with Diaphragm Seals Remain Essential

Despite emerging sensor technologies, these gauges maintain dominance in harsh environments due to their mechanical simplicity and adaptability. A 2024 industry forecast predicts 6.3% annual growth, driven by demand in LNG and renewable energy sectors. Partner with ISO 9001-certified manufacturers for guaranteed compliance and performance.

(bourdon tube pressure gauge with diaphragm seal)

FAQS on bourdon tube pressure gauge with diaphragm seal

Q: What is a bourdon tube pressure gauge with a diaphragm seal?

A: A bourdon tube pressure gauge with a diaphragm seal is a device that combines a bourdon tube mechanism with a diaphragm seal to measure high-pressure, corrosive, or viscous media. The diaphragm seal isolates the gauge from the process fluid, ensuring longevity and accuracy. It is ideal for harsh industrial environments.

Q: How to choose reliable bourdon tube pressure gauge with diaphragm seal manufacturers?

A: Look for manufacturers with certifications like ISO 9001, proven industry experience, and positive customer reviews. Ensure they offer customization, technical support, and compliance with international standards. Request product samples or case studies to verify quality.

Q: What are key features of a bourdon tube pressure gauge with diaphragm seal product?

A: Key features include robust construction (stainless steel or alloys), compatibility with aggressive media, and temperature resistance. Many models offer options like glycerin filling for vibration resistance and customizable dial sizes. Diaphragm seals are available in materials like Hastelloy or PTFE for chemical resistance.

Q: Where are bourdon tube pressure gauges with diaphragm seals commonly used?

A: They are used in industries like oil and gas, chemical processing, pharmaceuticals, and food production. These gauges handle aggressive fluids, high pressures, or extreme temperatures. Applications include pipeline monitoring, reactor vessels, and hydraulic systems.

Q: What factors affect bourdon tube pressure gauge with diaphragm seal quotes?

A: Quotes depend on materials (e.g., diaphragm seal type, housing grade), customization (size, pressure range), and order volume. Additional costs may include certifications, testing, or installation accessories. Compare quotes from multiple manufacturers to balance cost and quality.

-

High-Precision Mini Differential Pressure Gauge Compact & Durable Design

NewsMay.13,2025

-

Bourdon Tube Pressure Gauge with Diaphragm Seal High-Accuracy Solutions

NewsMay.13,2025

-

Wise Differential Pressure Gauge High-Precision & Reliable Solutions

NewsMay.12,2025

-

Fire Extinguisher Pressure Gauge in Red - Durable & Reliable Monitoring

NewsMay.12,2025

-

Rueger Diaphragm Pressure Gaauge High Accuracy & Durable Design

NewsMay.12,2025

-

Premium Differential Pressure Gauges High-Accuracy Solutions

NewsMay.11,2025