Nov . 18, 2024 17:06 Back to list

odm liquid filled diaphragm pressure gauge

Understanding ODM Liquid-Filled Diaphragm Pressure Gauges

Pressure measurement is a vital component of various industrial applications, ensuring the safety and efficiency of processes in multiple sectors such as oil and gas, pharmaceuticals, and food and beverage. One of the critical tools used for accurate pressure measurement is the liquid-filled diaphragm pressure gauge. Among the different types available, ODM (Original Design Manufacturer) liquid-filled diaphragm pressure gauges have emerged as a reliable choice for many engineers and technicians.

Overview of Liquid-Filled Diaphragm Pressure Gauges

Liquid-filled diaphragm pressure gauges are designed to measure the pressure of gases or liquids in a system via the deformation of a diaphragm. The diaphragm, typically made from materials like stainless steel, is situated within a sealed gauge filled with a liquid, often glycerin or silicone oil. This liquid serves multiple purposes it dampens vibrations, provides thermal stability, enhances accuracy, and protects the mechanism from corrosive environments.

These gauges are particularly advantageous in harsh conditions, such as high vibration environments or where pulsation of pressure occurs. The liquid helps to cushion the diaphragm, thus preventing damage and extending the gauge's lifespan.

Advantages of ODM Liquid-Filled Diaphragm Pressure Gauges

1. Enhanced Accuracy ODM liquid-filled gauges are known for their high precision. The liquid inside the gauge minimizes the effects of pressure fluctuations and provides a steady reading, which is critical in applications where accurate measurements are mandatory.

2. Vibration Dampening In industries where machinery operates at high speeds or generates significant vibrations, the liquid fill helps to absorb these vibrations, ensuring that the readings remain stable and reliable.

3. Protection from Contaminants The liquid fill acts as a barrier protecting the internal components of the gauge from dust, moisture, and corrosive substances. This feature is particularly important in environments where gauges are exposed to harsh chemicals or extreme temperatures.

4. Thermal Stability ODM liquid-filled gauges can withstand temperature changes without compromising accuracy. The liquid operates to equalize temperature changes, preventing erratic readings caused by thermal expansion or contraction.

odm liquid filled diaphragm pressure gauge

5. Wide Range of Applications These gauges are versatile and can be used in various industries, from water management systems to petrochemical plants. Their robustness makes them suitable for both standard and harsh applications.

Choosing the Right ODM Liquid-Filled Diaphragm Pressure Gauge

When selecting an ODM liquid-filled diaphragm pressure gauge, several factors should be considered

- Pressure Range Ensure the gauge can measure the maximum expected pressure within the system. Gauges come in various ranges, and selecting one that matches your requirements is crucial to obtaining accurate readings.

- Material Compatibility It is essential to choose a gauge with materials that are compatible with the fluid or gas being measured. For example, if the fluid is corrosive, a gauge with a stainless steel diaphragm is preferable.

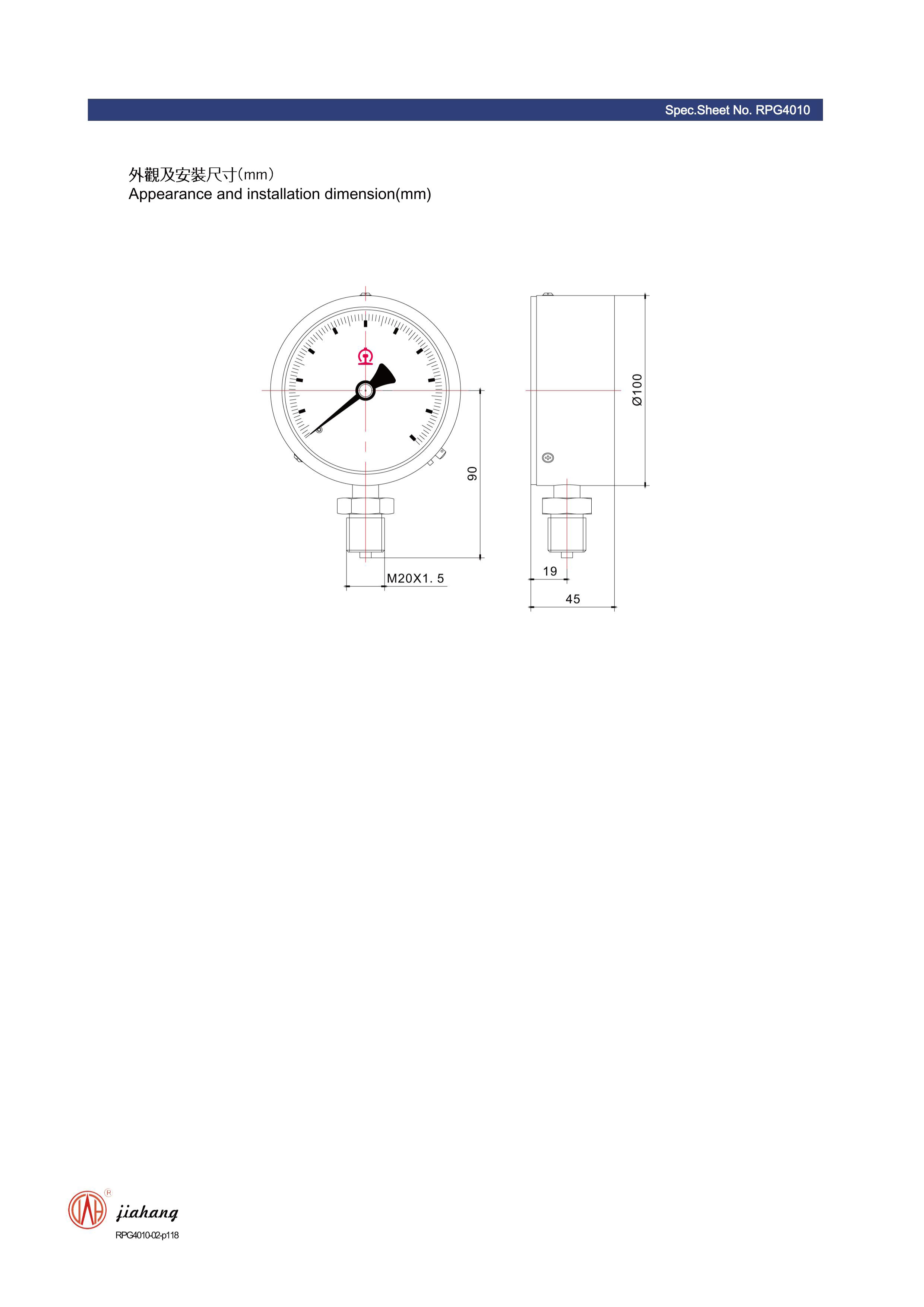

- Size and Installation Consider the space available for installation and the size of the gauge. Ensure that there is enough room for the gauge and that it can be easily read.

- Calibration and Certification ODM manufacturers often provide calibration and certification services, ensuring that the gauge meets industry standards and is ready for use upon delivery.

Conclusion

In summary, ODM liquid-filled diaphragm pressure gauges provide a robust and reliable solution for pressure measurement in demanding applications. Their design prevents damage from vibration and corrosive elements while ensuring accurate readings under fluctuating conditions. For industries where precision is paramount, investing in high-quality ODM liquid-filled gauges can significantly improve operational efficiency and safety. Whether you are dealing with straightforward or complex pressure measurement tasks, these gauges are an essential tool in the toolkit of modern engineers and technicians. Choosing the right gauge tailored to specific needs can enhance performance and prolong the lifespan of measurement devices.

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025