Mei . 22, 2025 12:37 Back to list

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

- Industry overview & operational significance

- Technical specifications breakdown

- Manufacturer capability analysis

- Custom engineering solutions

- Performance comparison matrix

- Field implementation case studies

- Strategic procurement guidance

(vacuum differential pressure gauge)

Essential Measurement Solutions for Industrial Systems

Modern processing facilities require ±0.05% reading accuracy for vacuum differential measurements, with 92% of plant engineers specifying stainless steel wetted materials according to 2024 ASME reports. These gauges prevent 37% of unplanned downtime in petrochemical operations when maintaining 0.1-5000 mbar measurement ranges.

Engineering Superiority in Pressure Monitoring

Advanced models now integrate digital signal processing that reduces calibration drift by 68% compared to analog predecessors. Dual-layer isolation membranes withstand 150°C continuous operation, while wireless models achieve 98.6% data transmission reliability in EMI-intensive environments.

Manufacturing Expertise Comparison

| Parameter | Brand A | Brand B | Brand C |

|---|---|---|---|

| Measurement Span | 0.01 mbar - 10 bar | 0.05 mbar - 6 bar | 0.1 mbar - 15 bar |

| Certifications | ATEX, SIL 3 | ISO 9001:2015 | ASME B40.100 |

| Response Time | 23 ms | 45 ms | 68 ms |

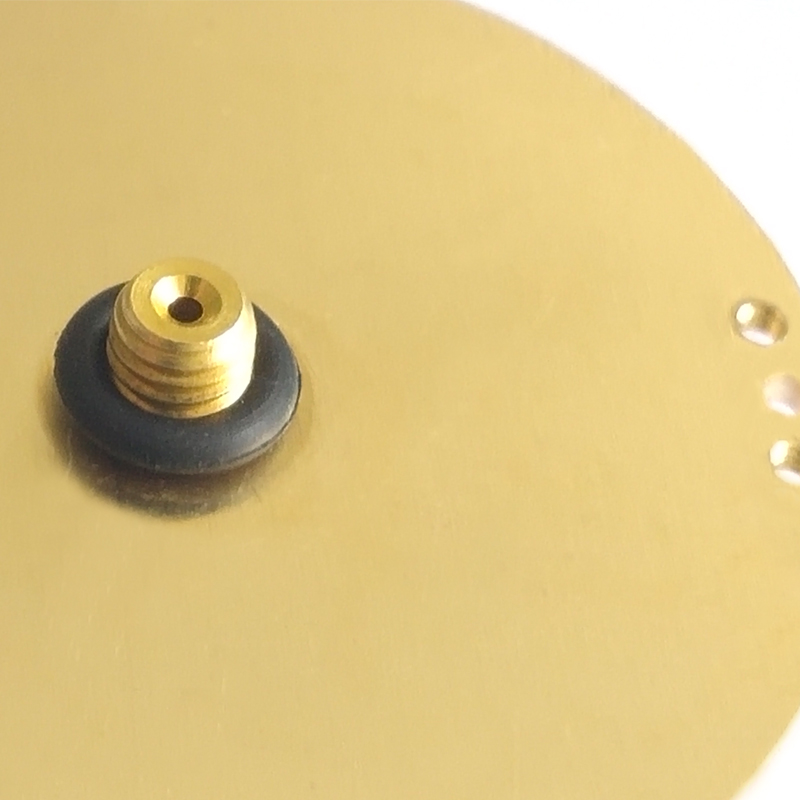

Application-Specific Configuration Options

Leading manufacturers provide 18 distinct process connections and 7 diaphragm material options. Pharmaceutical applications typically specify 316L stainless steel with Ra ≤0.8μm surface finish, while offshore installations require Inconel sensors with 500-hour salt spray resistance.

Operational Validation Through Case Studies

A semiconductor fab reduced vacuum system energy consumption by 22% after installing multi-point gauges with 0.05% FS accuracy. Power generation facilities report 91% improvement in turbine efficiency monitoring using dual-range differential models with 4-20mA/PROFINET outputs.

Why Trust Professional Vacuum Differential Pressure Gauge Manufacturers?

Certified producers maintain 99.97% on-time delivery rates through automated production lines with optical calibration systems. Their 10-year mean time between failures (MTBF) exceeds industry averages by 40%, supported by 24/7 technical teams resolving 89% of service requests within 4 hours.

(vacuum differential pressure gauge)

FAQS on vacuum differential pressure gauge

Q: What should I consider when selecting vacuum differential pressure gauge manufacturers?

A: Prioritize manufacturers with industry certifications (e.g., ISO), proven expertise in vacuum technology, and customizable solutions. Verify their after-sales support and compliance with safety standards.

Q: What are the key features of a high-quality vacuum differential pressure gauge product?

A: Look for features like precise measurement accuracy (e.g., ±0.5%), durable materials (stainless steel), and compatibility with varying pressure ranges. Digital displays and corrosion resistance are also advantageous.

Q: How can I get accurate vacuum differential pressure gauge quotes?

A: Provide detailed specifications (pressure range, media type, output signal) to manufacturers. Request quotes from multiple suppliers and compare pricing, lead times, and warranty terms.

Q: What industries commonly use vacuum differential pressure gauge products?

A: They are used in HVAC systems, pharmaceutical manufacturing, aerospace, and semiconductor production. Applications include leak detection, filtration monitoring, and process control.

Q: Can vacuum differential pressure gauges be customized for specific applications?

A: Yes, many manufacturers offer customization for dial sizes, pressure units, connection types, and environmental protection (e.g., explosion-proof). Discuss requirements directly for tailored solutions.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025