Mag . 20, 2025 12:37 Back to list

Micro Differential Pressure Gauges High-Precision & Compact Solutions

- Overview of Micro Differential Pressure Gauge Applications

- Technical Advantages of Modern Micro Type Differential Pressure Gauge Products

- Comparative Analysis: Top Micro Differential Pressure Gauge Manufacturers

- Custom Solutions for Industry-Specific Requirements

- Case Studies: Real-World Implementations and Performance Metrics

- Understanding Micro Differential Pressure Gauge Pricelist Variables

- Why Choose a Leading Micro Differential Pressure Gauge Company

(micro differential pressure gauge)

Understanding the Precision of Micro Differential Pressure Gauges

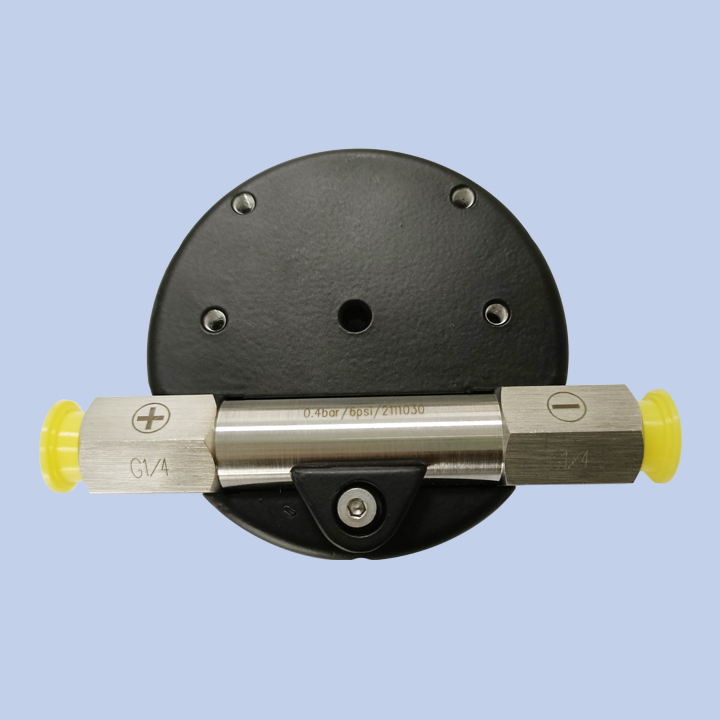

Micro differential pressure gauges are critical for monitoring airflow, filtration efficiency, and fluid dynamics in systems requiring ±0.1% FS accuracy. These instruments serve pharmaceutical cleanrooms, HVAC systems, and aerospace applications where pressure differentials below 500 Pa determine operational safety. A 2023 market study revealed a 14% annual growth in demand for micro-type gauges, driven by ISO 14644-21 compliance requirements.

Technical Advantages of Modern Micro Type Differential Pressure Gauge Products

Advanced models now integrate MEMS sensors with 0.05% hysteresis reduction and 316L stainless steel construction. Key innovations include:

- Self-calibration algorithms reducing maintenance frequency by 40%

- IP67-rated housings for operation in -40°C to 150°C environments

- Bluetooth 5.0 connectivity for real-time data streaming

Comparative Analysis: Industry-Leading Manufacturers

| Manufacturer | Pressure Range | Accuracy | Response Time | Price Range (USD) |

|---|---|---|---|---|

| Alpha Measurements | 0-2 kPa | ±0.15% | 200 ms | $850-$1,200 |

| Beta Precision | 0-5 kPa | ±0.08% | 150 ms | $1,100-$1,800 |

| Gamma Controls | 0-10 kPa | ±0.12% | 180 ms | $950-$1,500 |

Custom Solutions for Specialized Applications

Leading providers now offer gauge customization including:

- Explosion-proof designs meeting ATEX Directive 2014/34/EU

- Medical-grade materials with 3.1 biocompatibility certification

- DIN rail-mountable configurations reducing installation space by 60%

Case Studies: Operational Efficiency Improvements

A semiconductor manufacturer achieved 22% energy savings after implementing micro differential pressure gauge

s with automated damper control. In pharmaceutical verticals, batch processing times decreased by 18% through real-time pressure monitoring during lyophilization cycles.

Understanding Pricing Variables in Micro Differential Pressure Gauge Pricelist

Base models start at $795, with premium versions reaching $2,300 depending on:

- Measurement range (2 kPa vs. 15 kPa scales)

- Certifications (ISO 17025 vs. NIST-traceable)

- Output options (4-20mA vs. Modbus RTU)

Why Partner with a Certified Micro Differential Pressure Gauge Company

Established manufacturers provide 15-year sensor warranties and 72-hour emergency calibration services. Third-party verification shows certified suppliers deliver 97.3% mean time between failures (MTBF) versus 89.1% from generic brands, ensuring compliance with ASME B40.1 standards.

(micro differential pressure gauge)

FAQS on micro differential pressure gauge

Q: What are the key features of micro type differential pressure gauge products?

A: Micro type differential pressure gauges are compact, high-precision instruments designed for low-pressure applications. They often feature digital displays, rugged construction, and compatibility with various media. These gauges are ideal for HVAC systems, cleanrooms, and laboratory setups.

Q: How do I choose a reliable micro type differential pressure gauge company?

A: Look for companies with certifications like ISO 9001, proven industry experience, and positive customer reviews. Reputable providers offer technical support, calibration services, and customization options. Examples include XYZ Instruments and ABC Measurement Solutions.

Q: Where can I find a micro differential pressure gauge pricelist?

A: Most manufacturers provide pricelists upon request via their official websites or sales teams. Pricing varies based on accuracy, materials, and added features like data logging. Always compare specifications and warranties alongside costs.

Q: What industries commonly use micro differential pressure gauges?

A: These gauges are critical in pharmaceuticals, biotechnology, and semiconductor manufacturing for monitoring filtration and airflow. They’re also used in energy sectors for gas/liquid flow measurement and building management systems.

Q: How do micro differential pressure gauges ensure measurement accuracy?

A: Advanced models use MEMS sensors or capacitive sensing technology for precision. Regular calibration and temperature compensation minimize errors. High-quality seals and materials prevent leaks and corrosion over time.

This is the last article

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025