Ott . 30, 2024 23:23 Back to list

oem bellow type differential pressure gauge

Understanding OEM Bellow Type Differential Pressure Gauges

Differential pressure gauges are crucial instruments in various industrial applications, providing vital information about pressure differences in systems. Among these, the OEM bellow type differential pressure gauge stands out for its accuracy, reliability, and versatility. In this article, we will explore the features and applications of these gauges, highlighting their importance in process control and monitoring.

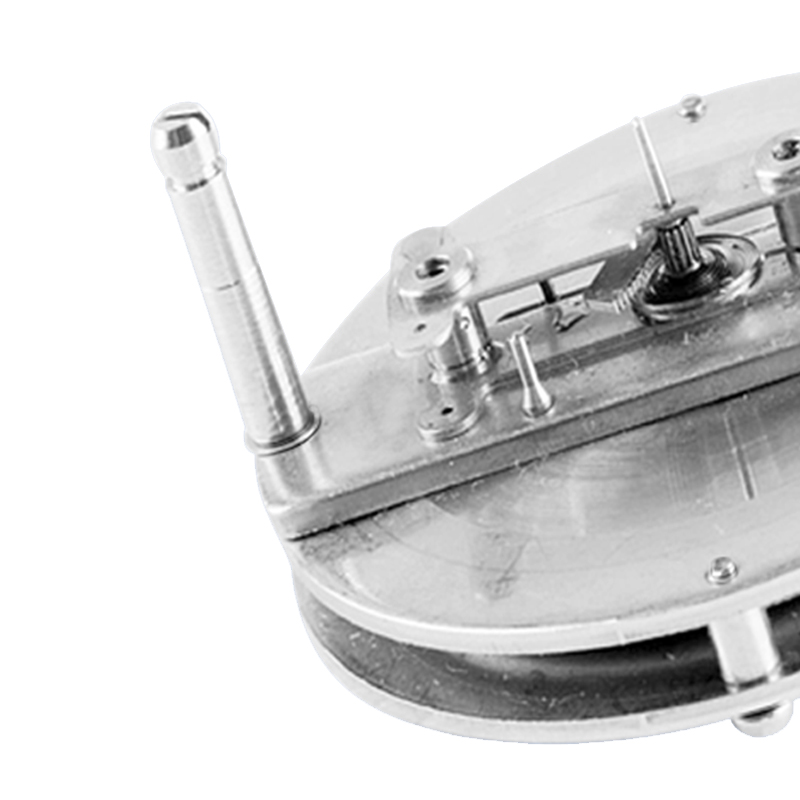

At its core, a differential pressure gauge measures the difference in pressure between two points within a system. The OEM bellow type gauge utilizes a bellow mechanism, which is sensitive to pressure variations. This type of gauge typically comprises two chambers separated by a flexible bellow. As pressure changes in either chamber, the bellow expands or contracts, enabling an accurate reading of the pressure difference. The movement of the bellow is translated into a rotational movement of the gauge’s needle, indicating the pressure difference on a dial.

One of the key advantages of OEM bellow type differential pressure gauges is their accuracy. They can provide precise readings even in low-pressure applications, making them suitable for various industries, including pharmaceuticals, food and beverage, and HVAC systems. Their design minimizes the effects of temperature variations and vibrations, ensuring that the readings remain stable and reliable under different operational conditions.

oem bellow type differential pressure gauge

Another notable feature of these gauges is their robustness. OEM manufacturers prioritize durability in their designs, often utilizing materials that resist corrosion and wear. This characteristic makes bellow type differential pressure gauges suitable for harsh environments where exposure to chemicals or extreme temperatures can compromise the performance of conventional gauges. By selecting the right materials, OEMs can tailor these pressure gauges for specific applications, ensuring their longevity and reliability.

The versatility of OEM bellow type differential pressure gauges is another reason for their popularity. They can be used in numerous applications, including filter monitoring, level measurement, and flow monitoring. For instance, in a filtration system, a differential pressure gauge can indicate when a filter is becoming clogged by measuring the pressure drop across the filter media. This information is critical for maintenance and helps to prevent unexpected system failures.

Moreover, the installation and maintenance of OEM bellow type differential pressure gauges are straightforward, which is essential in industrial settings where downtime can be costly. Most gauges come with easy-to-follow instructions, and regular maintenance typically involves simple checks to ensure they are functioning correctly.

In conclusion, OEM bellow type differential pressure gauges offer a reliable solution for measuring pressure differences in various industrial applications. Their accuracy, durability, and versatility make them a preferred choice for many sectors. By monitoring differential pressure, industries can enhance operational efficiency, ensure safety, and maintain equipment longevity. As technology continues to advance, we can expect further innovations in the design and functionality of these essential instruments, continuing to meet the evolving needs of modern industry.

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025