Oct . 30, 2024 15:32 Back to list

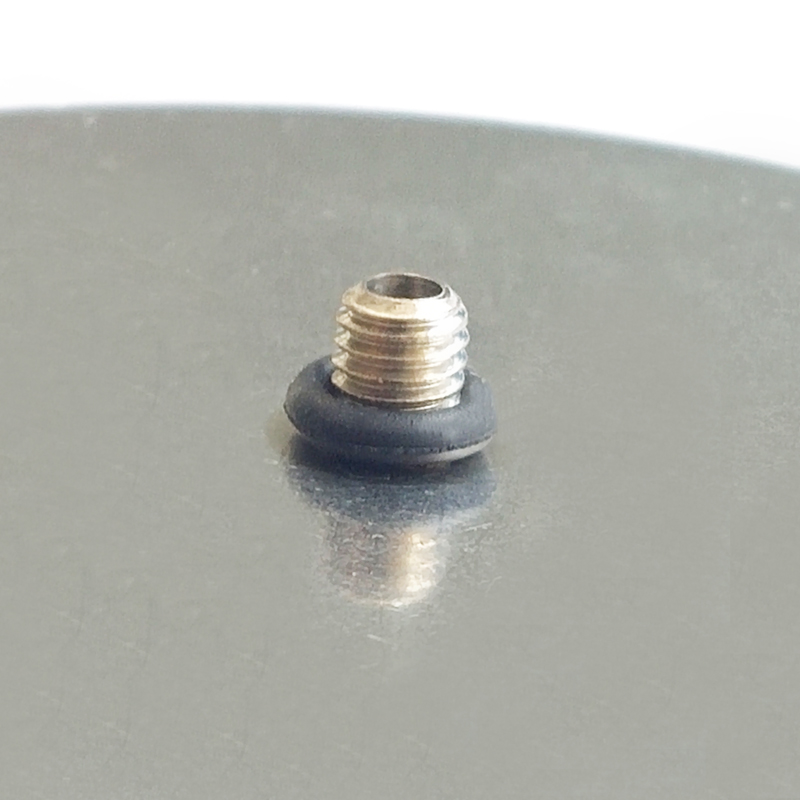

custom double diaphragm differential pressure gauge

Understanding Custom Double Diaphragm Differential Pressure Gauges

In various industrial applications, pressure measurement is crucial for ensuring safety, efficiency, and precision. Among the tools available for this purpose, custom double diaphragm differential pressure gauges stand out due to their unique design and operational benefits. These devices are engineered to offer highly accurate measurements of pressure differentials, making them indispensable in fields such as process engineering, HVAC systems, and fluid management.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points. This type of gauge is particularly vital in applications where pressure changes within a system can indicate potential issues, such as clogs, leaks, or pressure imbalances. The double diaphragm design enhances the accuracy and reliability of these measurements by using two flexible diaphragms that respond to the pressure differences more effectively than single diaphragm gauges.

The Design of Custom Double Diaphragm Gauges

The custom double diaphragm differential pressure gauge features two separate cavities separated by diaphragms. When there is a pressure difference, the diaphragms move accordingly, creating a mechanical movement that drives a needle or digital readout to provide a real-time measurement. The custom aspect allows for specific alterations in design, materials, and size to meet the unique requirements of various industries.

These gauges are often constructed using durable materials resistant to harsh environments, enabling them to withstand extreme temperatures, corrosive fluids, and high-pressure scenarios. The ability to customize these gauges means that they can be fitted with various options such as electrical outputs, visual alarms, or special calibrations, tailored to specific operational needs.

Benefits of Using Custom Double Diaphragm Gauges

custom double diaphragm differential pressure gauge

1. Enhanced Accuracy The dual diaphragm system significantly reduces the likelihood of errors in measurement caused by external factors and provides improved precision.

2. Durability and Reliability Custom designs allow for the use of robust materials that can withstand challenging environments, leading to longer service life and reduced maintenance needs.

3. Versatility These gauges can be customized for various fluids and gases, including those that are corrosive or viscous. Their adaptability makes them suitable for diverse applications in oil and gas, water treatment, pharmaceuticals, and more.

4. Safety Accurate pressure readings are essential for maintaining safe operating conditions. By using a double diaphragm system, the risk of catastrophic failure due to pressure mismanagement is significantly minimized.

5. Easy Integration Custom double diaphragm differential pressure gauges can be designed to integrate seamlessly into existing systems, enhancing functionality without requiring significant overhauls.

Conclusion

The importance of accurate differential pressure measurement in industrial applications cannot be overstated. Custom double diaphragm differential pressure gauges provide a reliable and flexible solution for a variety of pressure measurement needs. Their enhanced design facilitates precise measurements while offering durability and adaptability for various environments. Investing in these high-quality gauges ensures operational efficiency and safety, solidifying their place as a go-to instrument in pressure monitoring systems. As industries continue to evolve, the role of such advanced measurement tools will undoubtedly grow, supporting innovations and improvements across multiple sectors.

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025