May . 20, 2025 12:35 Back to list

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

- Overview of Pressure Gauges with Diaphragm Seals

- Technical Advantages and Performance Data

- Comparison of Leading Manufacturers

- Customization Options for Specific Applications

- Industry Use Cases and Success Stories

- Cost Analysis and Quotation Guidance

- Future Trends in Diaphragm Seal Pressure Measurement

(pressure gauges with diaphragm seals)

Understanding Pressure Gauges with Diaphragm Seals

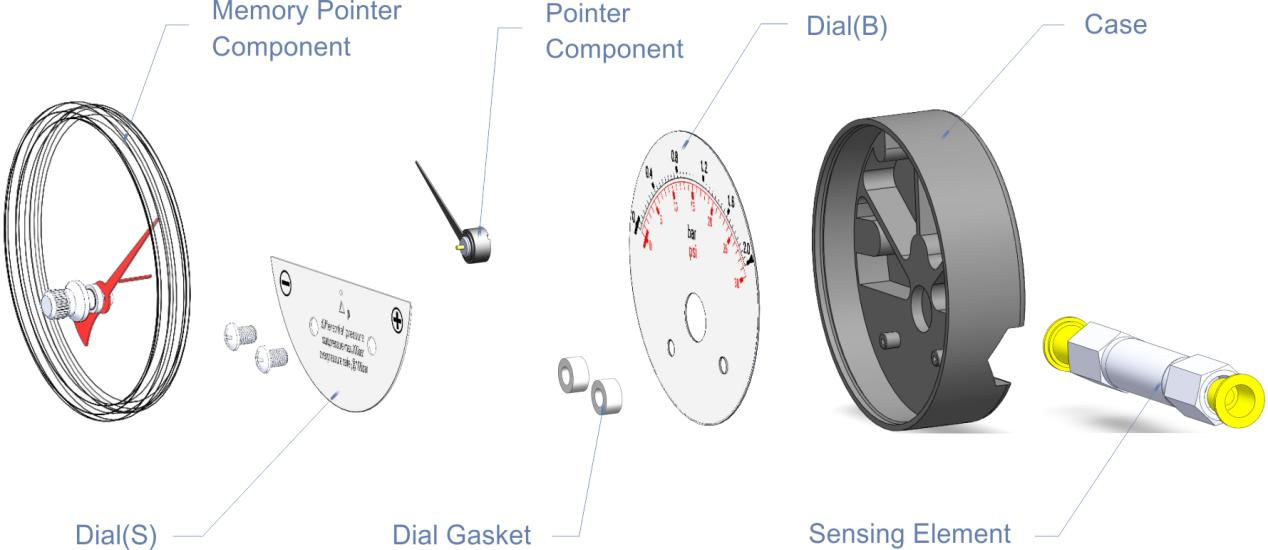

Pressure gauges with diaphragm seals are critical instruments designed for demanding industrial environments where corrosive, viscous, or high-temperature media require isolation from sensitive gauge components. These systems combine a stainless-steel diaphragm with a fill fluid to transmit pressure while protecting the gauge mechanism. Industries such as chemical processing, pharmaceuticals, and oil & gas rely on these devices for accurate, long-lasting measurements in aggressive conditions.

Technical Advantages and Performance Data

Modern diaphragm seal pressure gauges deliver ±0.5% accuracy even at extreme temperatures (-40°C to 400°C). Key innovations include:

- Hygienic designs with 3-A Sanitary Certification for food/pharma

- Flush-mounted diaphragms preventing media buildup

- Advanced fill fluids (silicone, glycerin, or halocarbon) for thermal stability

| Manufacturer | Accuracy | Max Pressure | Certifications |

|---|---|---|---|

| WIKA | ±0.25% | 16,000 psi | ATEX, ASME |

| Ashcroft | ±0.5% | 10,000 psi | ISO 9001 |

Customization Options for Specific Applications

Top pressure gauges with diaphragm seals

manufacturers offer:

- Material flexibility: 316L stainless steel, Hastelloy, or Monel diaphragms

- Connection types: Clamp, threaded, or flanged process connections

- Specialized configurations: Capsule-type seals for differential pressure measurement

Industry Use Cases and Success Stories

A refinery recently reduced maintenance costs by 40% after switching to diaphragm seal gauges with PTFE-coated diaphragms for HF alkylation units. Pharmaceutical clients report 99.8% reliability in CIP/SIP processes using electropolished seals meeting FDA standards.

Cost Analysis and Quotation Guidance

Standard pressure gauges with diaphragm seals product lines range from $350-$1,200 per unit. Premium models with silver-alloy fill fluid and wireless connectivity average $2,500. Request quotes specifying:

- Process media compatibility requirements

- Required certifications (PED, CRN)

- Ambient temperature ranges

Innovations in Diaphragm Seal Pressure Measurement

Leading pressure gauges with diaphragm seals manufacturers now integrate IoT capabilities, enabling real-time monitoring of seal integrity. Recent field tests show a 60% reduction in unplanned downtime when using predictive maintenance-enabled gauges. Emerging materials like graphene-enhanced diaphragms promise 3x longer service life in abrasive media applications.

(pressure gauges with diaphragm seals)

FAQS on pressure gauges with diaphragm seals

Q: What are the key benefits of using pressure gauges with diaphragm seals?

A: Pressure gauges with diaphragm seals prevent direct contact between the process media and the gauge, ensuring longevity. They are ideal for corrosive, viscous, or high-temperature media. This design also minimizes maintenance needs.

Q: How do I select reliable pressure gauges with diaphragm seals manufacturers?

A: Look for manufacturers with certifications like ISO 9001 and industry-specific compliance. Check for proven expertise in diaphragm seal technology and read customer reviews. Request product samples or case studies to assess quality.

Q: What factors influence pressure gauges with diaphragm seals quotes?

A: Quotes depend on materials (e.g., stainless steel, Hastelloy), diaphragm seal type, and customization. Order volume and additional features like certifications also affect pricing. Always compare quotes from multiple manufacturers.

Q: Can pressure gauges with diaphragm seals handle high-pressure applications?

A: Yes, these gauges are designed for high-pressure environments when paired with compatible diaphragm seals. Ensure the seal material and pressure range match your application. Consult manufacturers for specific requirements.

Q: How do I maintain pressure gauges with diaphragm seals?

A: Regularly inspect seals for damage or clogging, especially with viscous media. Clean the diaphragm surface using compatible solvents. Calibrate gauges periodically to ensure accuracy.

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025

-

Pressure Gauge with Diaphragm Seal & Manifold Reliable Industrial Solutions

NewsMay.18,2025

-

Digital Differential Pressure Gauge Price Precision Sensors & Best Deals

NewsMay.18,2025