Dec . 03, 2024 17:12 Back to list

Suppliers of Diaphragm Pressure Gauges for Accurate Measurement Solutions

Understanding Diaphragm Pressure Gauges and Their Suppliers

Diaphragm pressure gauges are essential instruments in various industrial applications. They measure the pressure of gases and liquids, converting mechanical motion into a readable output. Their robustness, accuracy, and reliability make them particularly valuable in sectors such as oil and gas, chemical processing, and HVAC systems. The selection of a high-quality diaphragm pressure gauge and the right supplier can significantly impact the efficiency and safety of industrial operations.

What is a Diaphragm Pressure Gauge?

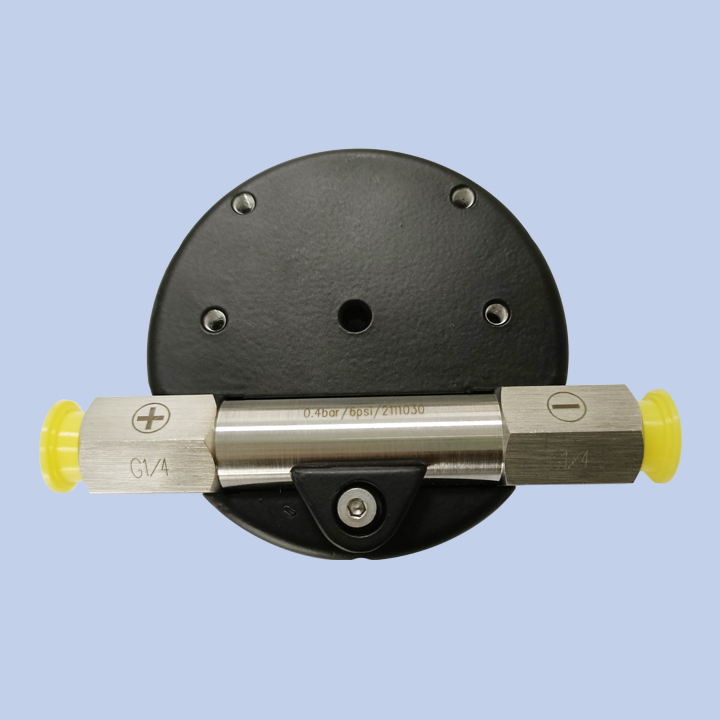

A diaphragm pressure gauge consists of a thin, flexible membrane (the diaphragm) that deflects when pressure is applied. This deflection is then translated into a mechanical movement, often displayed on a dial or via an electronic signal. Diaphragm gauges can measure differences in pressure (differential pressure), negative pressures (vacuum), and gauge pressure. Their design allows them to handle a variety of fluids, including corrosive materials, making them adaptable to various environments.

One of the primary advantages of diaphragm pressure gauges is their ability to minimize the effects of vibration and pulsation. This is crucial in settings where pressure fluctuations can occur, ensuring that readings remain steady and reliable. Additionally, many diaphragm gauges can be designed to withstand harsh operating conditions, including temperature extremes and exposure to chemicals.

Importance of Choosing the Right Supplier

When selecting a diaphragm pressure gauge, choosing a reputable supplier is critical. The quality of the gauge directly affects system performance, safety, and operational costs. A reliable supplier will offer products that adhere to stringent manufacturing standards, ensuring precision in measurement and longevity in performance.

Moreover, suppliers often provide additional value by offering technical support, calibration services, and advice on application-specific requirements. A knowledgeable supplier understands the diverse needs of their clients and can guide them in selecting the most appropriate products. This level of support is particularly important for organizations that may require custom solutions or those operating under stringent regulatory conditions.

Key Features to Consider When Choosing Suppliers

diaphragm pressure gauge suppliers suppliers

1. Product Range A good supplier should offer a comprehensive range of diaphragm pressure gauges, including various sizes, materials, and pressure ratings. This diversity ensures that you can find the right gauge for your specific application.

2. Quality Assurance Look for suppliers that adhere to industry standards both in product design and manufacturing processes. Certifications like ISO 9001 are indicators of a supplier's commitment to quality.

3. Technical Expertise The presence of skilled personnel who understand the technical aspects of pressure measurement can greatly enhance the buying experience. Suppliers who provide expert advice can help you avoid potential pitfalls and select products that meet your needs.

4. After-Sales Support Effective after-sales support, including warranty options and service agreements, reflects a supplier's confidence in their products. It also gives customers peace of mind knowing they can rely on support if issues arise post-purchase.

5. Innovative Solutions The best suppliers stay ahead by embracing new technologies and innovative solutions that can lead to improved measurement accuracy, enhanced durability, and user-friendly interfaces.

6. Customer Reviews and Reputation Researching customer feedback and the reputation of potential suppliers can provide insights into their reliability and the quality of their products. Engaging with industry peers and seeking recommendations can be invaluable.

Conclusion

In summary, diaphragm pressure gauges play a vital role in various industrial settings, and selecting the right supplier is crucial for ensuring operational success. By considering factors such as product range, quality assurance, technical expertise, and customer feedback, organizations can make informed purchasing decisions. Ultimately, a reliable supplier not only provides top-quality gauges but also fosters a partnership that contributes to improved operational efficiency and safety. Emphasizing these elements will help businesses navigate the market effectively, ensuring they harness the full potential of diaphragm pressure gauges in their applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025