Oct . 19, 2024 12:11 Back to list

Enhanced Diaphragm Seal Pressure Gauge for Accurate Measurement and Durability

Understanding the Wika Diaphragm Seal Pressure Gauge

In various industries, pressure measurement is crucial for ensuring safe and efficient operations. One of the key instruments used for this purpose is the pressure gauge. Among the different types available, the Wika diaphragm seal pressure gauge stands out as an essential tool, particularly in challenging environments. This article will explore the features, benefits, and applications of the Wika diaphragm seal pressure gauge, highlighting why it is a preferred choice for engineers and technicians alike.

What is a Diaphragm Seal Pressure Gauge?

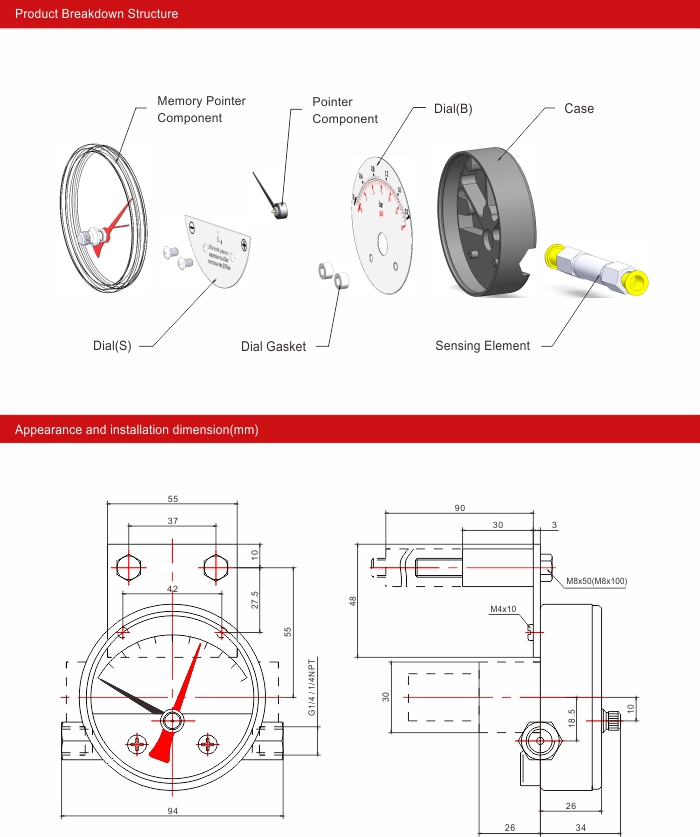

A diaphragm seal pressure gauge is designed to measure pressure in processes that involve corrosive, viscous, or high-temperature fluids. This gauge features a diaphragm that separates the measuring element from the process medium. The diaphragm is usually made from durable materials such as stainless steel or special alloys, allowing it to withstand harsh conditions. By using this design, the gauge protects the internal mechanisms from contamination and damage, thus ensuring accurate readings and extended service life.

Key Features of Wika Diaphragm Seal Pressure Gauges

1. Robust Construction Wika diaphragm seal pressure gauges are built with high-quality materials that can resist corrosion and abrasion. This makes them suitable for applications in chemical, oil and gas, and food industries where harsh substances are prevalent.

2. Flexible Design Wika offers a range of diaphragm seal gauges customizable to specific process requirements. Customers can choose different sizes, pressure ranges, and diaphragm materials to suit their particular applications.

3. High Accuracy These gauges are designed for high precision, providing reliable measurements even under fluctuating process conditions. The separation of the fluid from the mechanical parts enhances measurement accuracy, as any changes in fluid characteristics do not directly affect the gauge.

4. Wide Temperature Range Wika gauges are capable of operating effectively in both high and low-temperature environments. This versatility allows them to be used in a variety of processes, from cryogenic applications to those involving steam or hot gases.

wika diaphragm seal pressure gauge product

5. Easy Maintenance The design of Wika diaphragm seal pressure gauges allows for straightforward maintenance and calibration. This is particularly beneficial in industries where continuous operation is critical, allowing for quick service without significant downtime.

Benefits of Using Wika Diaphragm Seal Pressure Gauges

The advantages offered by Wika diaphragm seal pressure gauges extend beyond their construction. One of the most significant benefits is the enhanced safety they provide. By preventing hazardous process fluids from entering the gauge, they minimize the risk of leaks and potential accidents. Moreover, accurate pressure readings contribute to better control of process parameters, leading to improved efficiency and reduced operational costs.

Another considerable benefit is their adaptability in various applications. Whether monitoring pressure in a chemical reactor, ensuring the safe transit of fluids in pipelines, or controlling systems in food processing, these gauges are versatile enough to meet a wide array of industry needs.

Applications

Wika diaphragm seal pressure gauges are widely used across multiple sectors, including

- Chemical Processing For monitoring corrosive fluids and ensuring safe operation. - Oil and Gas Used in drilling and pipeline applications where fluids can be both viscous and hazardous. - Pharmaceuticals Essential for maintaining the integrity of sensitive processes. - Food and Beverage Ensures compliance with hygiene standards while measuring important process parameters.

Conclusion

In conclusion, Wika diaphragm seal pressure gauges represent a significant advancement in pressure measurement technology. Their robust design, high accuracy, and adaptability make them invaluable tools in industries where process integrity is paramount. By choosing Wika products, businesses can enhance their operational safety, efficiency, and reliability, making these gauges a wise investment for the future. Whether dealing with high-corrosion environments or extreme temperatures, Wika diaphragm seal pressure gauges deliver performance and peace of mind.

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025

-

Pressure Gauges with Diaphragm Seals High-Accuracy & Corrosion-Resistant

NewsMay.20,2025

-

Capillary Type Differential Pressure Gauge Precision Measurement Solutions

NewsMay.19,2025

-

Diaphragm Seal Pressure Gauges High Accuracy & Corrosion Resistance

NewsMay.19,2025