Jan . 14, 2025 09:50 Back to list

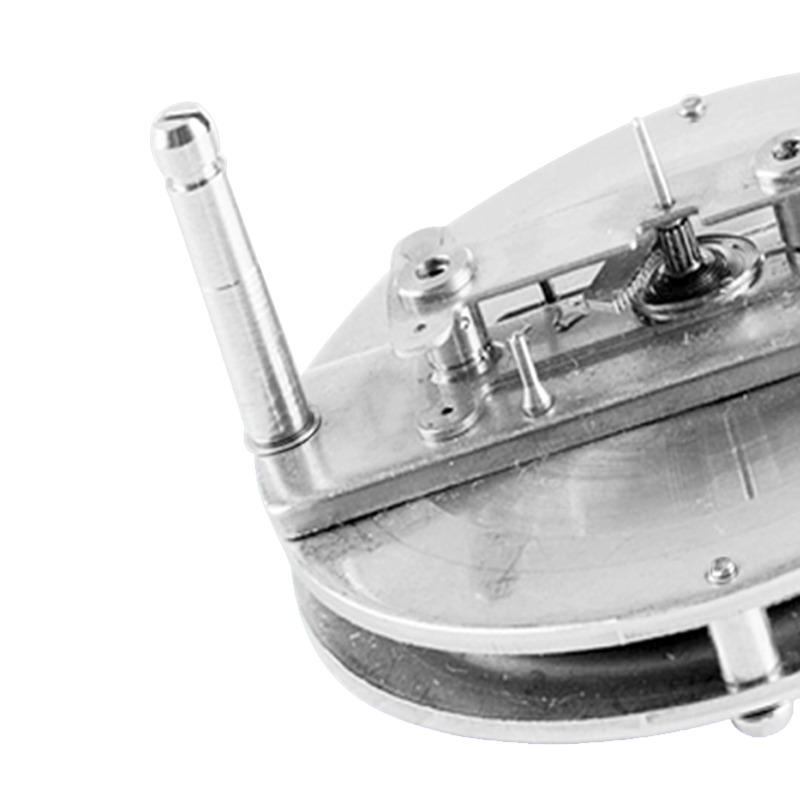

capacitance diaphragm pressure gauge

Capacitance Diaphragm Pressure Gauges Elevating Precision in Pressure Measurement

Innovation in capacitance diaphragm technology has also yielded advanced variants that incorporate smart features for real-time data transmission and remote monitoring. This digital integration plays a transformative role in industries pivoting towards automation and IoT, offering enhanced data analytics and a higher degree of process control. In pharmaceutical manufacturing, for instance, where precision and consistency are crucial, these smart features enable automated adjustments to maintain optimal production conditions, ensuring compliance with stringent regulatory standards. Capacitance diaphragm pressure gauges are supported by the expertise of manufacturers and engineers specialized in pressure measurement solutions. Their credibility and authoritative knowledge ensure that these devices not only meet but often exceed industry standards and regulatory requirements. The continuous advancement of this technology is backed by a foundation of rigorous testing, quality assurance, and field validation, bolstering trust among industry professionals. From a sustainability perspective, the precision offered by capacitance diaphragm pressure gauges contributes to environmentally responsible operations by optimizing resource use and minimizing waste. In industries with high environmental impact potential, such as petrochemical operations, these gauges support initiatives aimed at reducing emissions and energy consumption, in alignment with global sustainability goals. As businesses continue to navigate the complexities of modern industrial landscapes, the demand for reliable and accurate pressure measurement solutions remains robust. Capacitance diaphragm pressure gauges are not just instruments; they are strategic assets that empower engineers and operators to achieve excellence in process management. Their integration into complex systems reflects a commitment to operational excellence and sustainability, embodying the principles of experience, expertise, authoritativeness, and trustworthiness. In conclusion, the capacitance diaphragm pressure gauge stands out as a paragon of precision instrumentation. Its capacity to deliver consistent, accurate measurements under demanding conditions ensures its place as an essential component in a wide array of industrial applications. By embracing such advanced technology, industries not only safeguard their operations but also position themselves at the forefront of innovation and efficiency.

Innovation in capacitance diaphragm technology has also yielded advanced variants that incorporate smart features for real-time data transmission and remote monitoring. This digital integration plays a transformative role in industries pivoting towards automation and IoT, offering enhanced data analytics and a higher degree of process control. In pharmaceutical manufacturing, for instance, where precision and consistency are crucial, these smart features enable automated adjustments to maintain optimal production conditions, ensuring compliance with stringent regulatory standards. Capacitance diaphragm pressure gauges are supported by the expertise of manufacturers and engineers specialized in pressure measurement solutions. Their credibility and authoritative knowledge ensure that these devices not only meet but often exceed industry standards and regulatory requirements. The continuous advancement of this technology is backed by a foundation of rigorous testing, quality assurance, and field validation, bolstering trust among industry professionals. From a sustainability perspective, the precision offered by capacitance diaphragm pressure gauges contributes to environmentally responsible operations by optimizing resource use and minimizing waste. In industries with high environmental impact potential, such as petrochemical operations, these gauges support initiatives aimed at reducing emissions and energy consumption, in alignment with global sustainability goals. As businesses continue to navigate the complexities of modern industrial landscapes, the demand for reliable and accurate pressure measurement solutions remains robust. Capacitance diaphragm pressure gauges are not just instruments; they are strategic assets that empower engineers and operators to achieve excellence in process management. Their integration into complex systems reflects a commitment to operational excellence and sustainability, embodying the principles of experience, expertise, authoritativeness, and trustworthiness. In conclusion, the capacitance diaphragm pressure gauge stands out as a paragon of precision instrumentation. Its capacity to deliver consistent, accurate measurements under demanding conditions ensures its place as an essential component in a wide array of industrial applications. By embracing such advanced technology, industries not only safeguard their operations but also position themselves at the forefront of innovation and efficiency.

Share

Latest news

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025