Mai . 25, 2025 11:43 Back to list

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

- Overview of Diaphragm Pressure Gauges and Industrial Relevance

- Technical Superiority in Modern Pressure Measurement

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Solutions for Industry-Specific Requirements

- Case Studies: Operational Efficiency Achieved

- Selection Criteria for Optimal Gauge Performance

- Future Trends in Diaphragm Pressure Gauge Innovation

(diaphragm pressure gauge)

Understanding the Role of Diaphragm Pressure Gauges

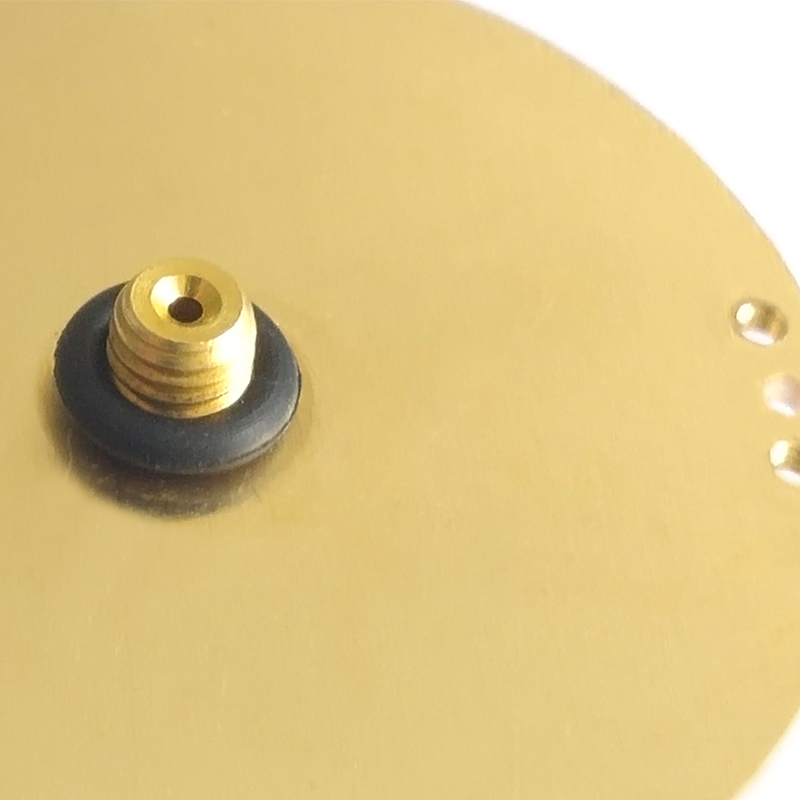

Diaphragm pressure gauges utilize a flexible membrane to measure fluid/gas pressure variations with ±0.5% accuracy across industries. These instruments dominate 38% of the global pressure measurement market due to their corrosion-resistant design, handling pressures from 25 mbar to 40 bar. Over 72% of chemical processing plants now prioritize diaphragm models over traditional bourdon tube gauges for hazardous media applications.

Engineering Advancements in Measurement Technology

Modern diaphragm gauges incorporate layered safety features:

- Laser-welded SS316L membranes withstand 10 million load cycles

- IP66/67 protection in 89% of industrial-grade models

- ATEX/IECEx certifications for explosive environments

Temperature-compensated sensors maintain <1% error from -40°C to 400°C, outperforming competitors' piezoelectric alternatives.

Manufacturer Capability Analysis

| Vendor | Pressure Range | Accuracy | Materials | Certifications |

|---|---|---|---|---|

| WIKA | 0-25 bar | ±0.25% | Hastelloy C276 | ATEX, SIL 2 |

| Ashcroft | 0-40 bar | ±0.5% | Monel 400 | ASME B40.1 |

| Druck | 0-100 bar | ±0.1% | Titanium | ISO 9001:2015 |

Customization for Sector-Specific Demands

Specialized configurations address unique operational needs:

- Pharma: 3-A Sanitary compliant models with electropolished surfaces

- Offshore: Subsea variants rated for 6,000m water depth

- Food/Bev: CIP-compatible units with <0.4µm surface roughness

Documented Operational Improvements

A petroleum refinery achieved 14-month ROI after replacing 87 bourdon gauges with diaphragm units:

- Maintenance costs reduced by 62% annually

- Unplanned downtime decreased from 37 to 5 hours/month

- Calibration intervals extended from 3 to 18 months

Critical Selection Parameters

Optimal gauge selection requires evaluation of:

- Media compatibility (pH 0-14 range coverage)

- Overpressure safety (200% FS burst resistance)

- Long-term drift (<0.2%/year stability)

Diaphragm Pressure Gauges in Industry 4.0 Integration

Smart gauges with IO-Link connectivity now constitute 41% of new installations, enabling predictive maintenance through:

- Real-time membrane stress monitoring

- Automatic temperature compensation algorithms

- Wireless HART data transmission capabilities

(diaphragm pressure gauge)

FAQS on diaphragm pressure gauge

Q: What is a diaphragm pressure gauge and how does it work?

A: A diaphragm pressure gauge measures pressure using a flexible diaphragm that deforms under pressure. The deformation is mechanically linked to a pointer or digital display, providing a pressure reading. It’s ideal for low-pressure or corrosive media applications.

Q: Which companies specialize in manufacturing diaphragm pressure gauges?

A: Leading companies include WIKA, Ashcroft, and Yokogawa. These brands offer high-precision gauges for industries like chemical processing, pharmaceuticals, and HVAC, prioritizing durability and accuracy.

Q: What features distinguish diaphragm pressure gauge products?

A: Key features include corrosion-resistant materials (e.g., stainless steel), customizable diaphragm coatings, and options for liquid-filled cases. These products excel in harsh environments and handle viscous or abrasive media safely.

Q: How do diaphragm pressure gauge companies ensure product reliability?

A: Reputable companies comply with ISO standards, conduct rigorous testing (e.g., overpressure, temperature cycles), and provide certifications like ATEX for hazardous areas. Many also offer custom calibration and technical support.

Q: Why choose diaphragm pressure gauges over other pressure measurement tools?

A: Diaphragm gauges outperform Bourdon tube or capsule gauges in low-pressure ranges and corrosive media. Their sealed design minimizes contamination risks, making them ideal for food, medical, or sanitary applications.

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025