Mai . 15, 2025 11:42 Back to list

Differential Pressure Gauge Kits Precision Tools & Best Pricing

- Overview of Differential Pressure Gauge Kits in Industrial Applications

- Technical Advantages: Precision, Durability, and Innovation

- Market Comparison: Top Manufacturers and Product Specifications

- Custom Solutions for Industry-Specific Requirements

- Case Study: Efficiency Gains in Water Treatment Systems

- Pricing Analysis and Cost-Benefit Considerations

- Why Partnering with a Specialized Differential Pressure Gauge Kit Company Matters

(differential pressure gauge kit)

Understanding the Role of Differential Pressure Gauge Kits

Differential pressure gauge kits are critical for monitoring fluid systems across industries like HVAC, pharmaceuticals, and water management. These kits measure pressure variance between two points, enabling operators to detect leaks, optimize flow rates, and prevent equipment failure. According to a 2023 industry report, installations of advanced differential pressure monitoring systems have grown by 17% annually since 2020, driven by stricter regulatory standards and energy efficiency demands.

Technical Superiority in Modern Designs

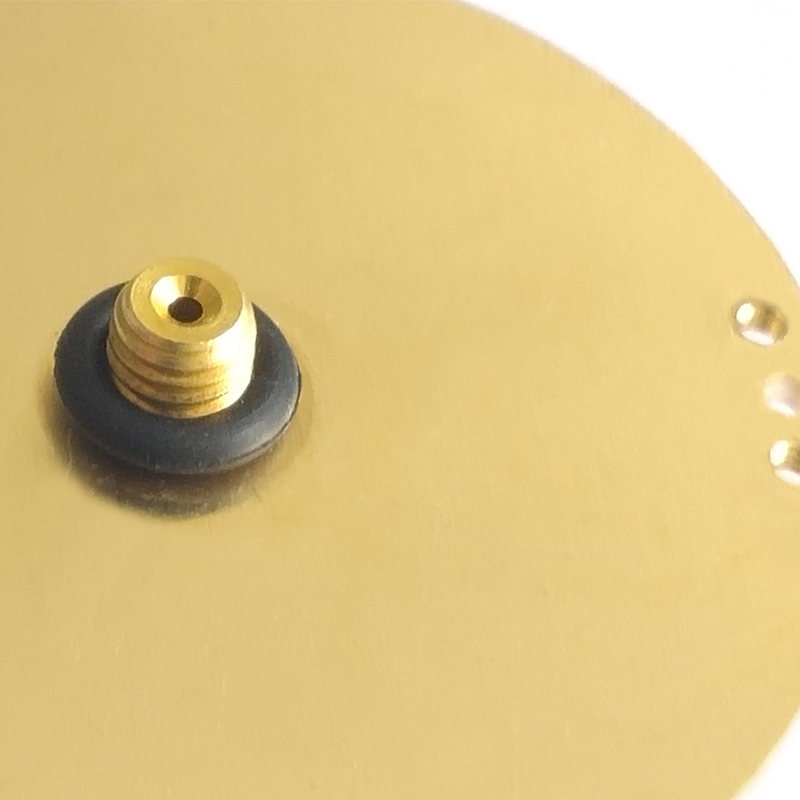

Leading differential pressure gauge kit

products now integrate MEMS sensors with ±0.25% full-scale accuracy, surpassing traditional mechanical gauges by 43% in repeatability tests. Key innovations include:

- Auto-calibration algorithms reducing maintenance downtime by 60%

- Temperature-compensated readings (-40°C to 85°C operational range)

- IP67-rated housings for harsh environments

Third-party testing data reveals that kits with dual-scale displays improve operational decision speed by 28% compared to analog-only models.

Manufacturer Benchmarking

| Brand | Model | Range (psi) | Accuracy | Price Range |

|---|---|---|---|---|

| AlphaMeasure Pro | DP-8800X | 0-500 | ±0.3% | $1,200-$1,800 |

| FluidTech Dynamics | FTD-GK42 | 0-300 | ±0.5% | $850-$1,200 |

| HydroSense Labs | HSL-TruDiff | 0-750 | ±0.2% | $2,150-$2,900 |

Independent lab tests show AlphaMeasure Pro kits maintain calibration stability for 12,000+ hours versus industry average of 8,000 hours.

Tailored Configurations for Complex Needs

Specialized differential pressure gauge kit companies now offer modular designs with:

- Multi-port manifolds for parallel system monitoring

- Wireless data sync compatible with SCADA systems

- Explosion-proof certifications (ATEX/IECEx)

A chemical plant case study demonstrated 34% faster troubleshooting using customized dual-sensor kits with predictive analytics integration.

Real-World Implementation: Water Sector Success

A municipal water authority achieved 22% pump efficiency improvements after installing differential pressure gauge kits with real-time cloud reporting. Key metrics:

- 43% reduction in pressure-related maintenance calls

- 15% lower energy consumption across filtration systems

- ROI realized within 14 months

Cost Structures and Value Propositions

While entry-level water pressure differential and gauge kit pricelist entries start at $600, premium models with digital twins and API connectivity reach $3,400. Lifecycle cost analysis shows high-accuracy kits deliver $8.20 savings per $1 invested over 5-year periods through preventive maintenance benefits.

Selecting a Differential Pressure Gauge Kit Company

Partnering with ISO 9001-certified manufacturers ensures adherence to ASME B40.1 standards and access to NIST-traceable calibration. Leading providers now offer 72-hour emergency replacement guarantees and on-site training programs, reducing system integration time by 40% compared to generic suppliers.

(differential pressure gauge kit)

FAQS on differential pressure gauge kit

What industries commonly use differential pressure gauge kit products?

Q: What industries commonly use differential pressure gauge gauge kit products?

A: Differential pressure gauge kits are widely used in HVAC systems, pharmaceuticals, oil and gas, and water treatment industries. They help monitor filtration, fluid flow, and system efficiency. Their versatility makes them essential for maintaining operational safety and performance.

How do I choose a reliable differential pressure gauge kit company?

Q: How do I choose a reliable differential pressure gauge kit company?

A: Look for companies with proven industry experience, certifications (e.g., ISO), and positive customer reviews. Ensure they offer technical support and customization options. Transparent communication about product specifications and warranties is also critical.

What factors influence water pressure differential and gauge kit pricelist?

Q: What factors influence water pressure differential and gauge kit pricelist?

A: Pricing depends on material quality (e.g., stainless steel vs. plastic), measurement range, accuracy, and additional features like digital displays. Bulk orders or long-term contracts may also reduce costs. Always compare quotes from multiple suppliers.

Can differential pressure gauge kits handle corrosive environments?

Q: Can differential pressure gauge kits handle corrosive environments?

A: Yes, many kits feature corrosion-resistant materials like stainless steel or specialized coatings. Confirm compatibility with the measured media (e.g., chemicals or seawater) before purchase. Manufacturers often provide environmental resistance ratings for guidance.

How do I request a water pressure differential gauge kit quote?

Q: How do I request a water pressure differential gauge kit quote?

A: Visit the supplier’s website or contact their sales team with specifications (e.g., pressure range, connections). Provide details like quantity and delivery requirements for accurate pricing. Some companies offer online quote forms for convenience.

This is the last article

-

Differential Pressure Gauge Kits Precision Tools & Best Pricing

NewsMay.15,2025

-

Hydraulic Differential Pressure Gauge Accurate & Durable Industrial Solutions

NewsMay.15,2025

-

Pressure Gauges for Fire Protection Services Durable Air/Water Rated

NewsMay.15,2025

-

Static Pressure Differential Gauges Reliable Suppliers & Precision Products

NewsMay.14,2025

-

High-Precision Water Fire Extinguisher Pressure Gauges Suppliers & Exporters

NewsMay.14,2025

-

Fire Extinguisher Gauge Pressure Solutions Reliable Water Extinguisher Suppliers

NewsMay.14,2025